A two-stage intensive roasting process that highlights the style of cinnabar smoke

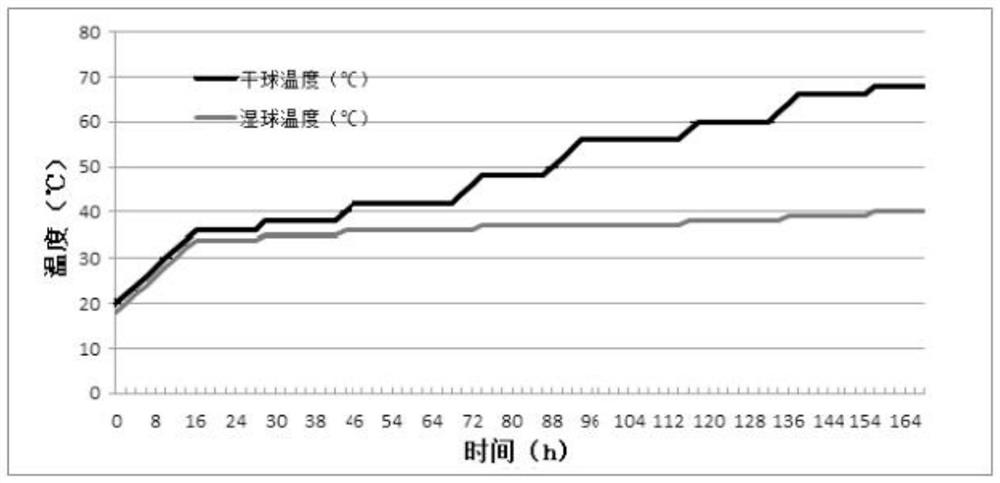

An intensive roasting, two-stage technology, applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of difficult to show the mellow aroma of cinnabar tobacco, large deviation of temperature and humidity control, and less sensory glutinous rice aroma. , to achieve the synchronization of dry leaves and aroma, pure smoke, and reduce the effect of moldy smoke rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] At the Yuxi Research and Experimental Base of Yunnan Tobacco Agricultural Science Research Institute, the lower, middle and fully ripe tobacco leaves of Yunyan 87 cinnabar tobacco were mixed and cured for experiments, of which about 40% were suitable for ripening tobacco leaves and about 60% were fully ripe tobacco leaves.

[0040] 1. Preparation before roasting: The roasting room used in the test is a coal-fired airflow ascending intensive roasting room. Overhaul the intensive barn for test roasting to ensure that the heating system and mechanical equipment are operating normally, the smoke chamber and walls are in good condition, and the temperature and humidity sensors are normal; one temperature and humidity sensor is hung on the ceiling of the barn and the other is hung In the bottom shed of the barn, the temperature sensing head is 5-10cm above the leaf tip.

[0041] 2. Tobacco weaving: the density of weaving smoke is 7 kg / rod, and the reasonable smoke density is ...

Embodiment 2

[0045] In the experimental base of Yunnan Tobacco Agricultural Science Research Institute, the upper part of Yunyan 87 cinnabar tobacco leaves transported from Chengjiang City was roasted for a mixed curing test, in which the first-ripe tobacco leaves accounted for 85%, and the appropriate-ripe tobacco leaves accounted for 15%.

[0046] 1. Preparation before roasting: The oven used in the test is a dense oven with electric heating and air flow descending. Overhaul the intensive barn for test roasting to ensure that the heating system and mechanical equipment are operating normally, the smoke chamber and walls are in good condition, and the temperature and humidity sensors are normal. Two temperature and humidity sensors are used. One hangs on the top floor of the oven, and the other hangs on the bottom floor of the oven. The temperature sensing head is 5-10cm away from the leaf tip.

[0047] 2. Compiled smoke: the density of compiled smoke is 6.5 kg / rod, and the reasonable s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com