Automatic detection method for continuous increase of vibration of mechanical equipment

An automatic detection and mechanical equipment technology, applied in measuring devices, computer components, measuring ultrasonic/sonic/infrasonic waves, etc., can solve equipment abnormalities, and it is difficult to solve the problems of continuous growth detection and impact of mechanical equipment vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is further described below in conjunction with accompanying drawing:

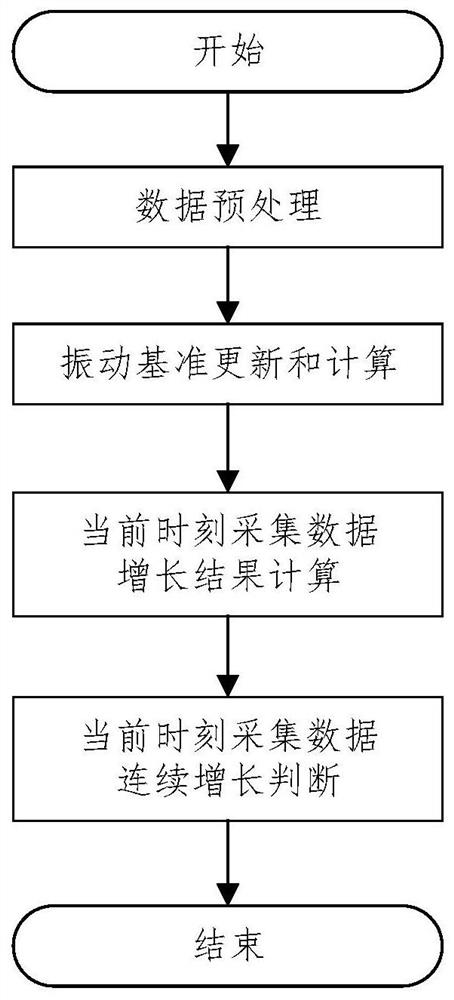

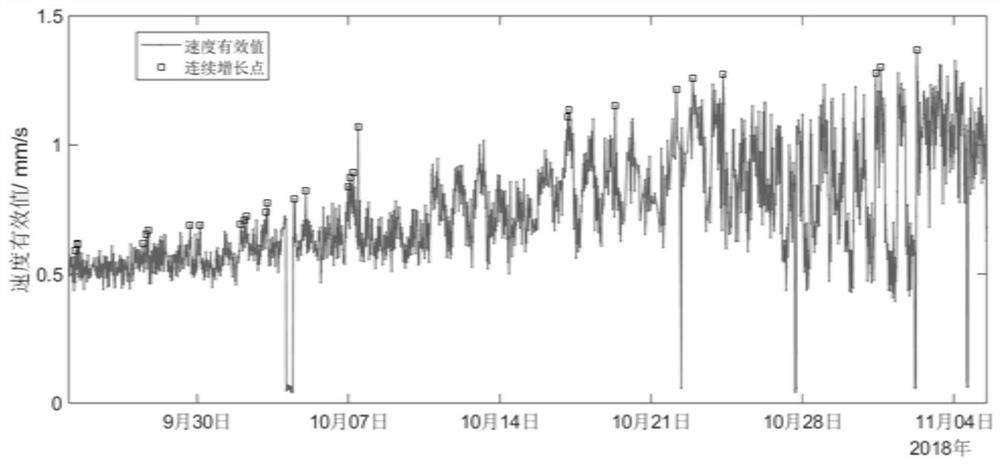

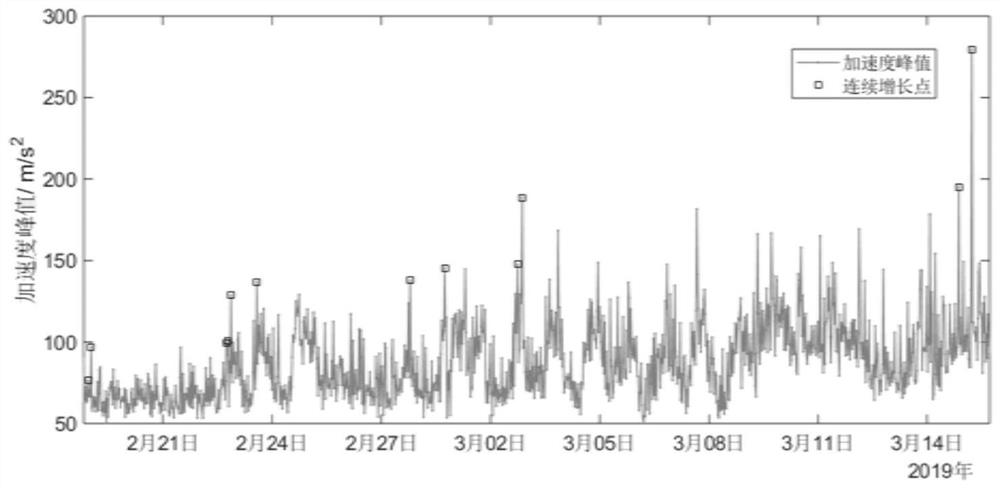

[0032] see Figure 1 to Figure 3 , an automatic detection technology for continuous growth of mechanical equipment vibration, comprising the following steps:

[0033] Step 1: Preprocessing the collected data at the current moment.

[0034] The vibration signal waveform data collected at the current moment of equipment vibration monitoring is subjected to feature extraction, and the extracted eigenvalue V is subjected to over-limit data cleaning and shutdown data cleaning preprocessing.

[0035] Over-limit cleaning: According to the measurable range of the vibration sensor of the equipment, judge whether the vibration characteristic value V collected at the current moment exceeds the range. If it exceeds the range, the vibration collected at the current moment is not available, and no follow-up analysis is required! Otherwise, you need to continue to the subsequent analysis ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com