Eccentric shaft composite size detection tool clamp and detection method

A dimension detection and tooling fixture technology, which is applied in the direction of measuring devices, manufacturing tools, workpiece clamping devices, etc., can solve problems such as clamping errors, reduced detection efficiency, and eccentric shaft amount detection errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

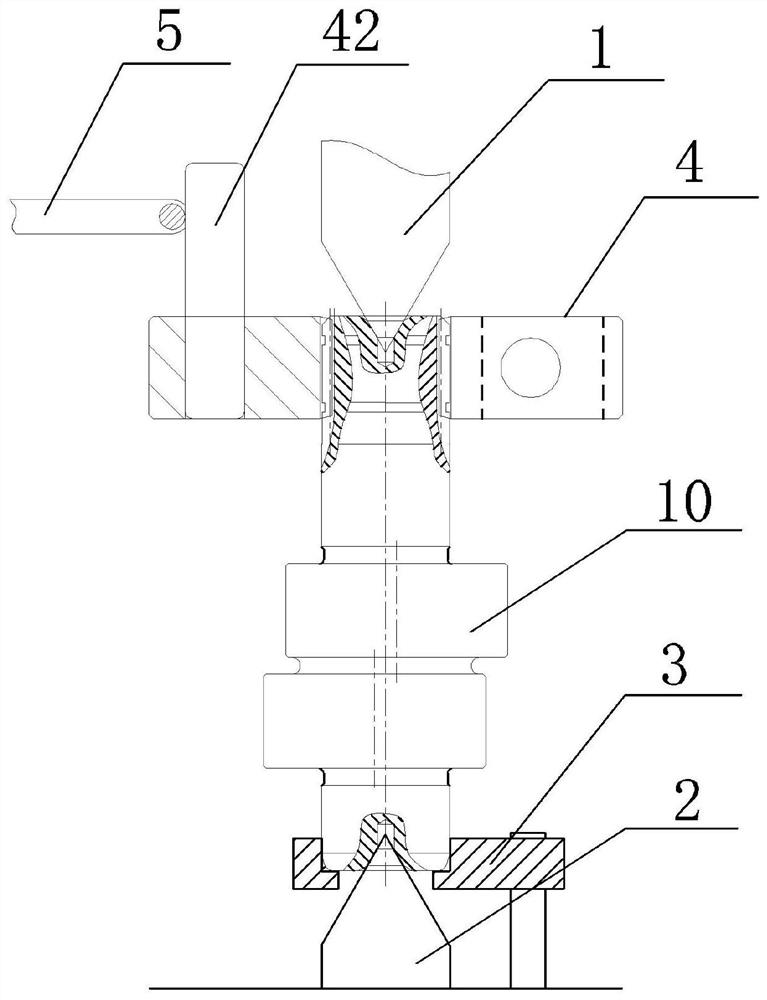

[0043] see figure 1 , figure 1 It is a structural schematic diagram of an eccentric shaft composite dimension detection fixture disclosed in the present invention.

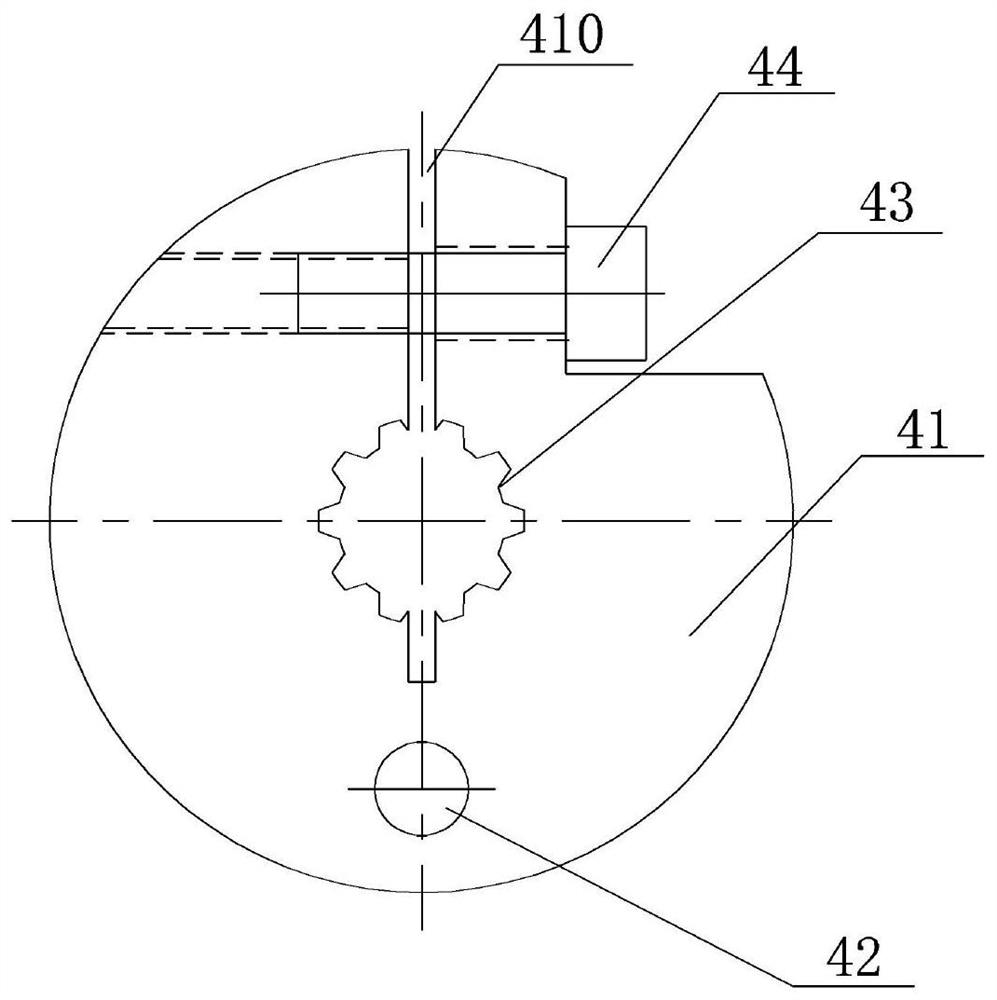

[0044] An eccentric shaft compound size detection fixture, comprising an upper positioning center 1, a lower positioning center 2, a driving clamp 3, a spline angle detection device 4, and a detection head 5, and an eccentric shaft 10 is placed on the upper positioning center 1 and the lower positioning center 2 for positioning, the driving clamp 3 is set above the lower positioning center 2, which is used to hold the eccentric shaft and drive it to make a circular motion, the spline angle detection device 4 is located under the upper positioning center 1, and is meshed and connected to the eccentric On the shaft 10, the detection head 5 is used to measure the composite dimension of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com