Guide vane opening analog quantity segmented open-loop control and speed regulator PID closed-loop control combined control method and system

A technology of guide vane opening and control method, which is applied in the direction of control system type, control algorithm type, engine control, etc., and can solve the problem of being easily affected by water hammer reaction and unit inertia, opening control has static deviation, active power Problems such as slow adjustment speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

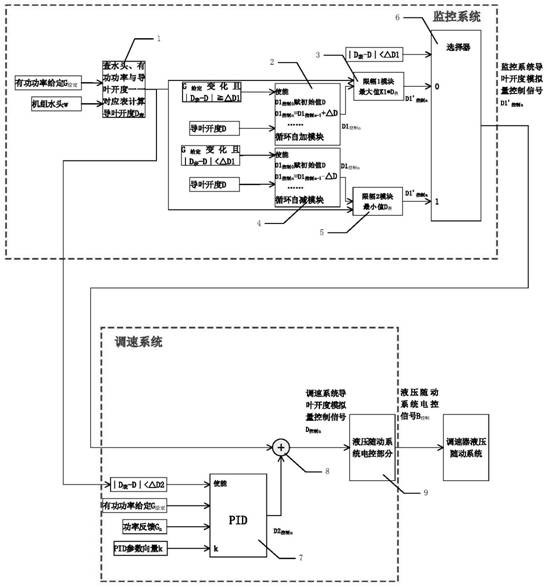

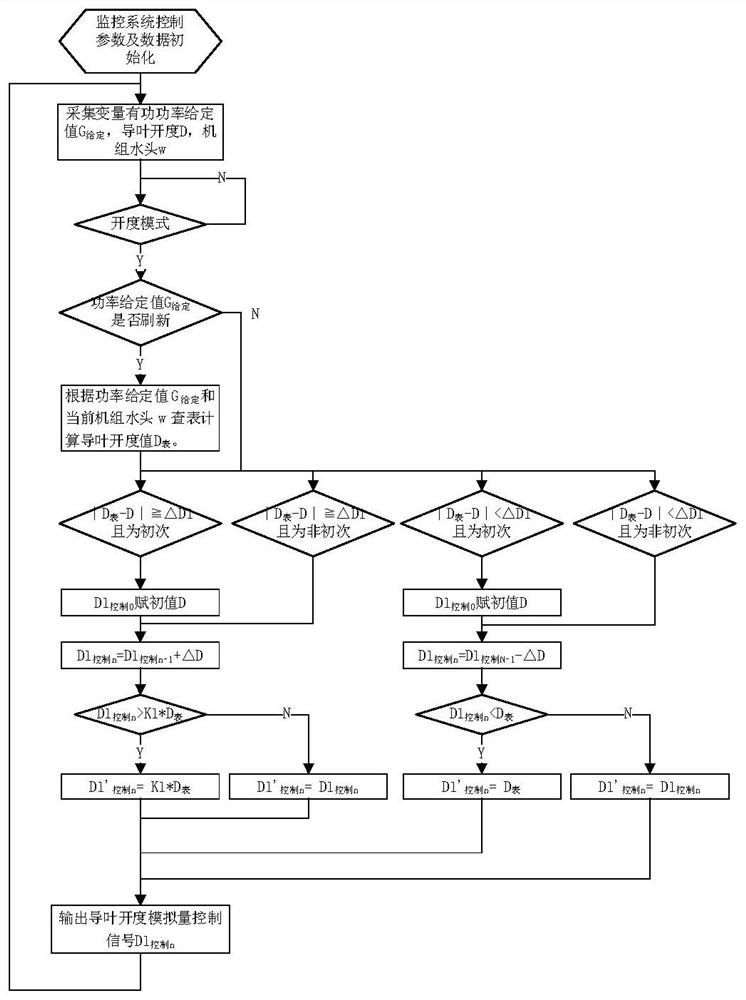

[0116] The invention belongs to the field of computer electric control systems of hydropower stations, and relates to a brand-new control method and structure of a monitoring system and a speed regulation system of a hydropower station. The control method and structure of the combination of governor PID closed-loop control. This method is based on the corresponding data table of water head, active power and guide vane opening. The PID closed-loop control method outputs the control signal of the hydraulic servo system. The combination of the two is a new method for fast and precise adjustment of the active power of the unit, aiming at solving the problem of slow active power adjustment in the opening mode when the power closed-loop conventional pulse adjustment method is adopted. , the adjustment process is easily affected by the water hammer reaction and the inertia of the unit, and under the pure open-loop control mode, there is a deviation in the data table corresponding to ...

Embodiment 2

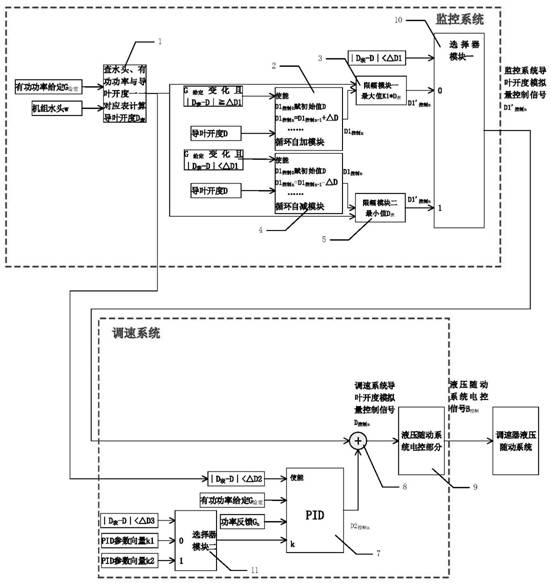

[0167] In order to further improve the performance and quality of the small-range or terminal adjustment of the guide vane opening and active power of the unit, in a hydropower station monitoring system opening mode guide vane opening analog segmented open-loop control combined with governor PID closed-loop control Based on the optimization and improvement of the control method and structure, the variable parameter PID closed-loop control is realized, and a control method combining the segmented open-loop control of the opening mode guide vane opening analog value of the monitoring system of the hydropower station and the variable parameter PID closed-loop control of the governor is formed. structure.

[0168] This method is based on the corresponding data table of water head, active power and guide vane opening. The variable parameter PID closed-loop control method outputs the control signal of the hydraulic servo system. The combination of the two provides a new method for q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com