Ore stoping method for reducing mining and cutting work amount of VCR method

A technology of engineering quantity and ore, which is applied in surface mining, underground mining, special mining, etc., can solve the problems that are not conducive to strong excavation of mines, continuous mining of strong mining, large mining and cutting engineering volume, and low operating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

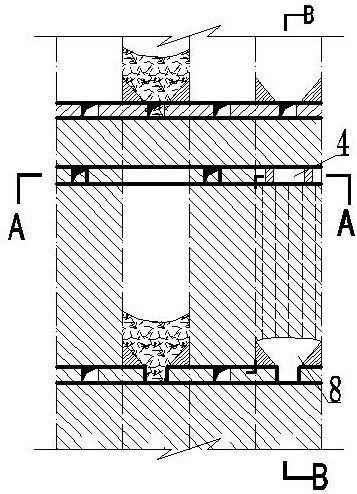

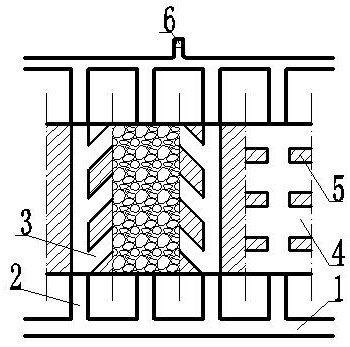

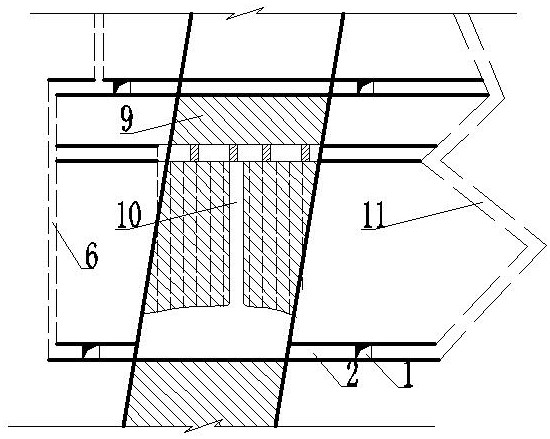

[0016] Combine below Figure 1 to Figure 6 , to further illustrate the present invention.

[0017] As shown in the figure, a method of ore recovery that reduces the amount of mining and cutting work by the "VCR" method includes the following steps: Step 1, digging the ramp to the layered depth of the ore body mining; Step 2, according to mine geology and ground pressure The management plan determines the number of multiple middle sections; step 3, construct the bottom structure in the lowermost middle section, and multiple middle sections share a bottom structure; step 4, excavate rock drilling chambers in the upper part of each middle section; step 5, according to each middle section Large-diameter deep-hole rock drilling is carried out at a high altitude; step six, ore mining, the stope adopts the mining method of "every three mining one" and mining from bottom to top.

[0018] Conventional "VCR" mining method mining quasi-engineering layout is as follows: Figures 1 to 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com