An intelligent dust-removing double-sided knitting machine and double-sided knitting process that automatically stops when the thread is broken

A knitting machine, double-sided technology, applied in knitting, weft knitting, warp knitting and other directions, can solve the problems of increasing production costs of enterprises, poor dust removal effect, defective cloth and other problems, so as to prevent thread loss and avoid material loss, the effect of expanding the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

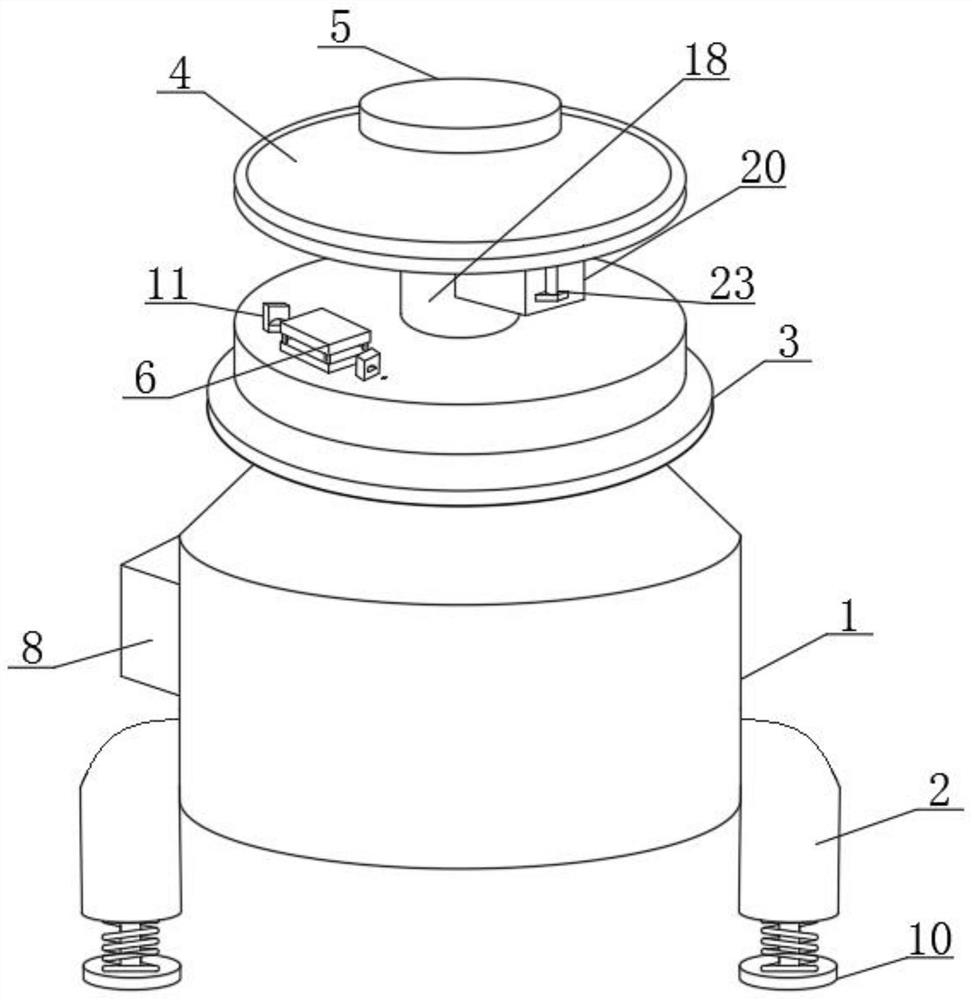

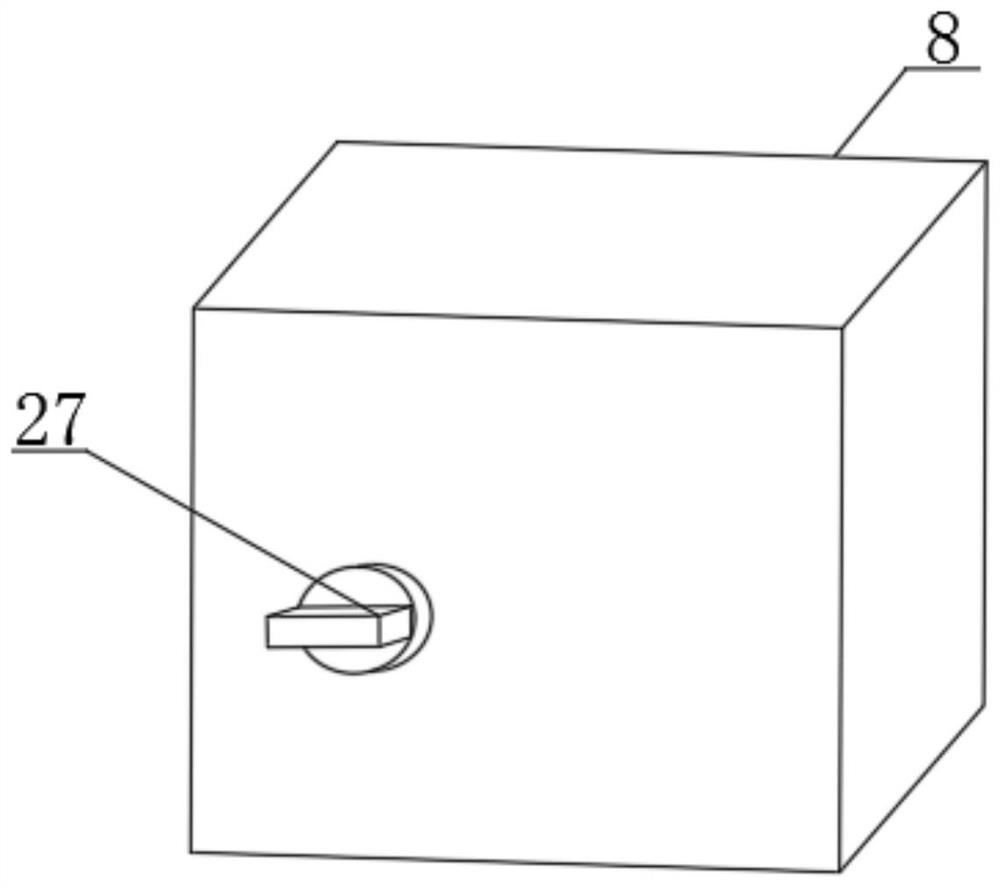

[0045] see figure 1 , an intelligent dust-removing double-knitting machine that automatically stops when the thread is broken, comprising a casing 1, the lower end of the casing 1 is fixedly connected with a stabilizing leg 2, and the lower end of the stabilizing leg 2 is fixedly connected with a vibration-reducing mechanism 10, The outer side of the casing 1 is fixedly connected with a power supply box 8, the upper end of the casing 1 is fixedly connected with a wire reel 3, the upper end of the wire reel 3 is fixedly connected with an induction box 6, and the upper end of the wire reel 3 is fixedly connected There is a main beam 18, the outer side of the main beam 18 is rotatably connected with a collar 19, the other end of the collar 19 is fixedly connected with a box body 20, and a shaft moving mechanism is arranged between the main beam 18 and the box body 20 26, the inside of the box 20 is provided with a dust removal mechanism 21, the upper end of the box 20 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com