Multiple-part inner housing for a steam turbine

A technology of inner shell and shell, which is applied in the direction of engine components, mechanical equipment, machines/engines, etc., can solve the problems of low tonnage and castability, heavy inner shell parts, expensive nickel-based materials, etc., and achieve cost savings , expand the supplier system, expand the effect of production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

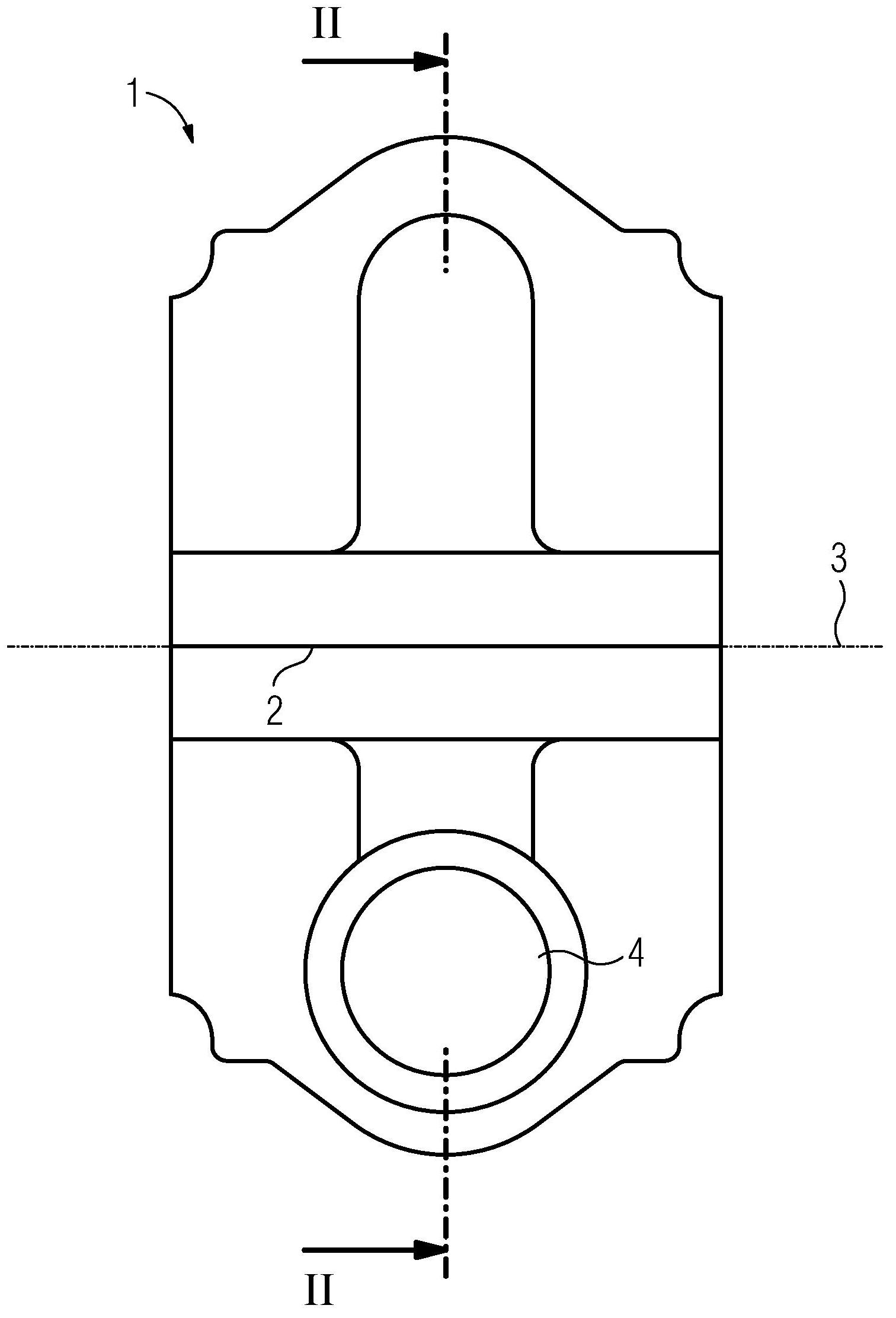

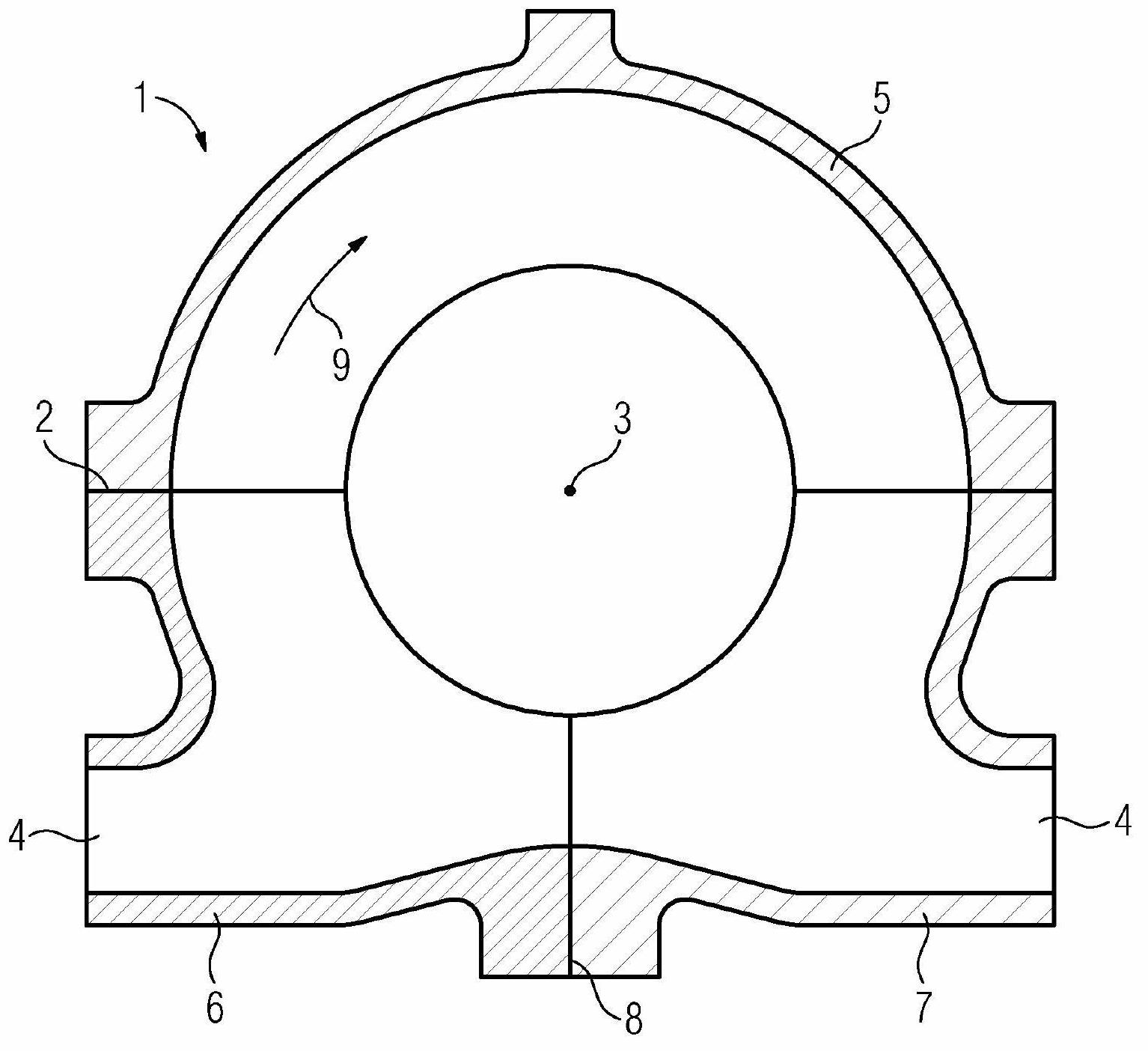

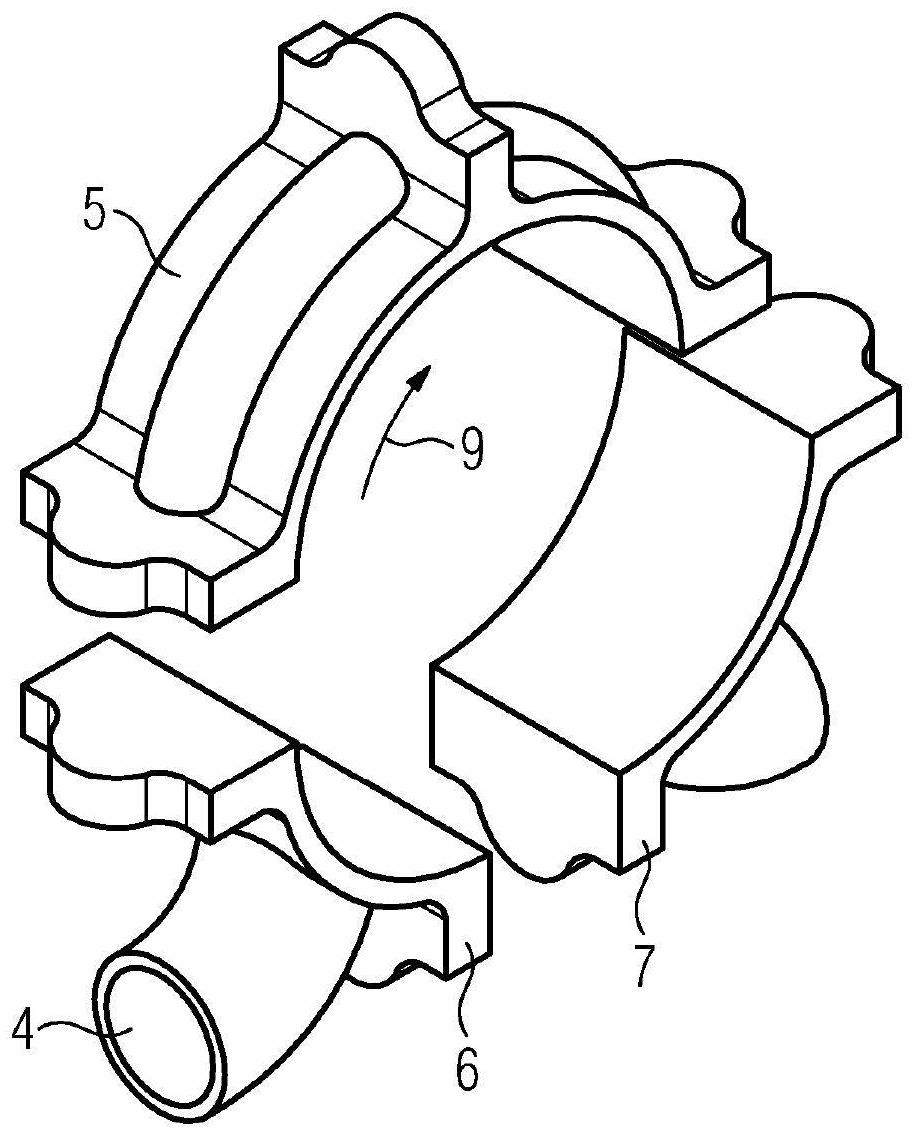

[0026] figure 1 A side view of the inner housing 1 of the fluid machine is shown. Such a fluid machine can be, for example, a steam turbine or a gas turbine. The following embodiments relate to steam turbines. The inner housing 1 includes a horizontal joint surface 2 and is substantially symmetrical about an axis of rotation 3 . A rotor, not shown in detail, is mounted rotatably about an axis of rotation 3 within the inner housing 1 .

[0027] The upper inner housing parts 5 , 10 , 11 are formed above the horizontal joint surface 3 and the lower inner housing parts 6 , 7 are formed below the horizontal joint plane 2 . The lower inner housing parts 6 , 7 below the horizontal joint surface 2 essentially have the inflow connection 4 . figure 1 Both an inner housing consisting of three inner housing parts and an inner housing consisting of four inner housing parts are shown.

[0028] figure 2 show figure 1 The section along the line A of the inner housing 1 in . The inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com