Engineering bacterium, treatment method of ornithine-containing solution and kit

A treatment method, ornithine technology, is applied in the biological field to achieve the effects of high product added value, high catalytic activity, and reduced separation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Embodiment 1 Construction of Ornithine Racemase Engineering Bacteria

[0076] Construction of genetically engineered bacteria expressing ornithine racemase: according to the amino acid sequence (NCBI accession number: CBH21408.1) of the reported ornithine racemase orr derived from Clostridium sticklandii (ATCC12662), after codon optimization, the obtained Such as the nucleotide sequence of SEQ ID: NO.1.

[0077] The whole gene was synthesized, and restriction sites NcoI and XhoI were designed at both ends, and subcloned into the vector pET28a to obtain the recombinant plasmid pET28a-orr.

[0078] The constructed recombinant plasmid pET28a-orr was transformed into the Escherichia coli expression host BL21(DE3) by the calcium chloride method to obtain the ornithine racemase expression strain E.coli BL21(DE3) / pET28a-orr.

[0079] The transformation step of the recombinant plasmid can be,

[0080] S1. Add kanamycin (50 μg / ml) to the LB solid medium, the day before the tra...

Embodiment 2

[0087] The construction of embodiment 2 ornithine decarboxylase engineering bacteria

[0088] Construction of genetically engineered bacteria expressing ornithine decarboxylase: select primers, replicate ornithine decarboxylase on Escherichia coli MG1655 by PCR, and obtain the nucleotide sequence containing SEQ ID: NO.2.

[0089] The nucleotide sequence containing SEQ ID: NO.2 was connected to the vector pET28a to obtain the recombinant plasmid pET28a-speC.

[0090] The constructed recombinant plasmid pET28a-speC was transformed into Escherichia coli expression host BL21(DE3) by calcium chloride method to obtain ornithine racemase expression strain E.coli BL21(DE3) / pET28a-speC.

[0091] The transformation step of the recombinant plasmid can be,

[0092] S1. Add kanamycin (50 μg / ml) to the LB solid medium, the day before the transformation reaction, invert the plate and save;

[0093] S2, prepare two experimental groups respectively,

[0094] The first group, plasmid DNA gro...

Embodiment 3

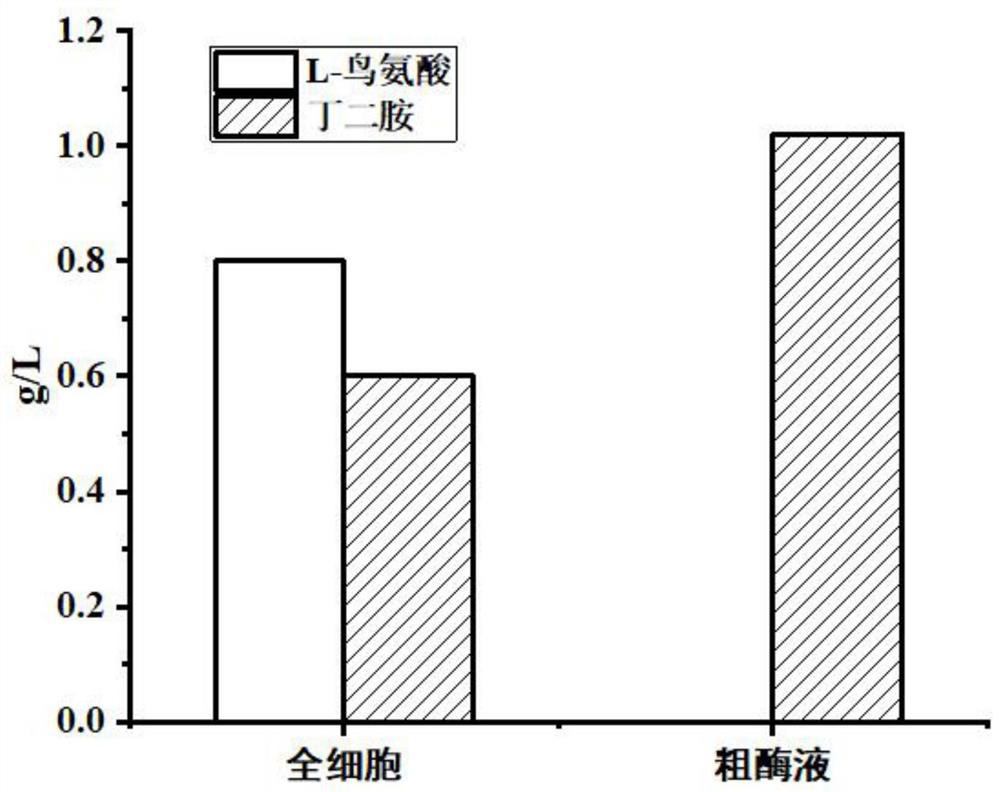

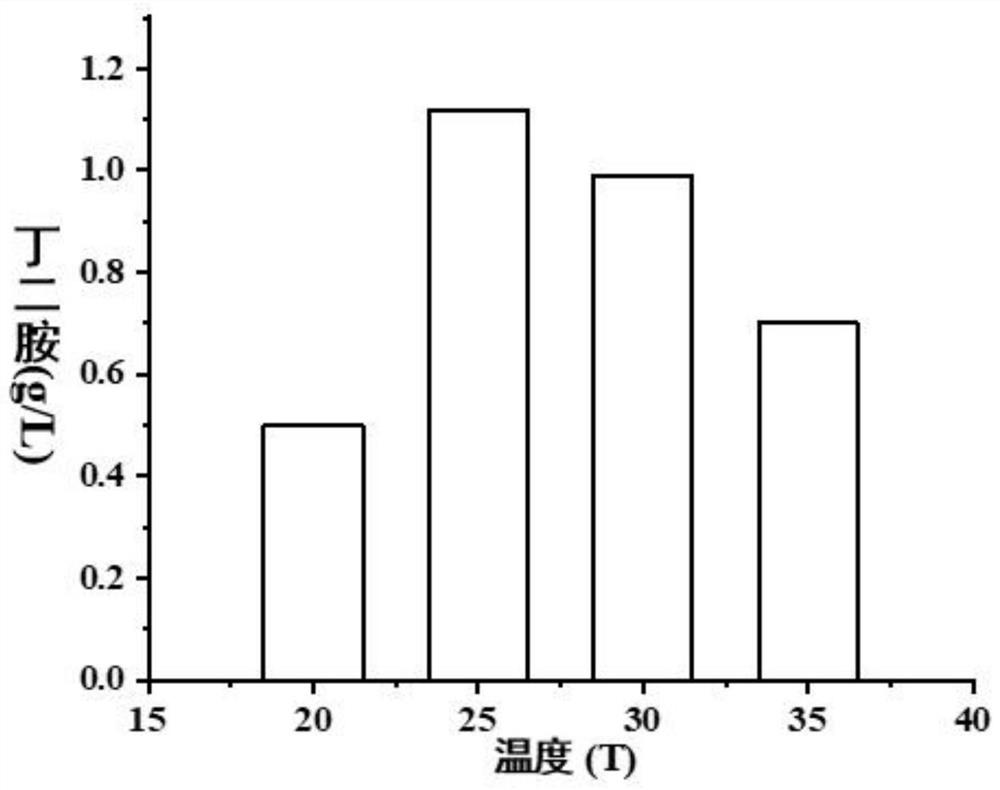

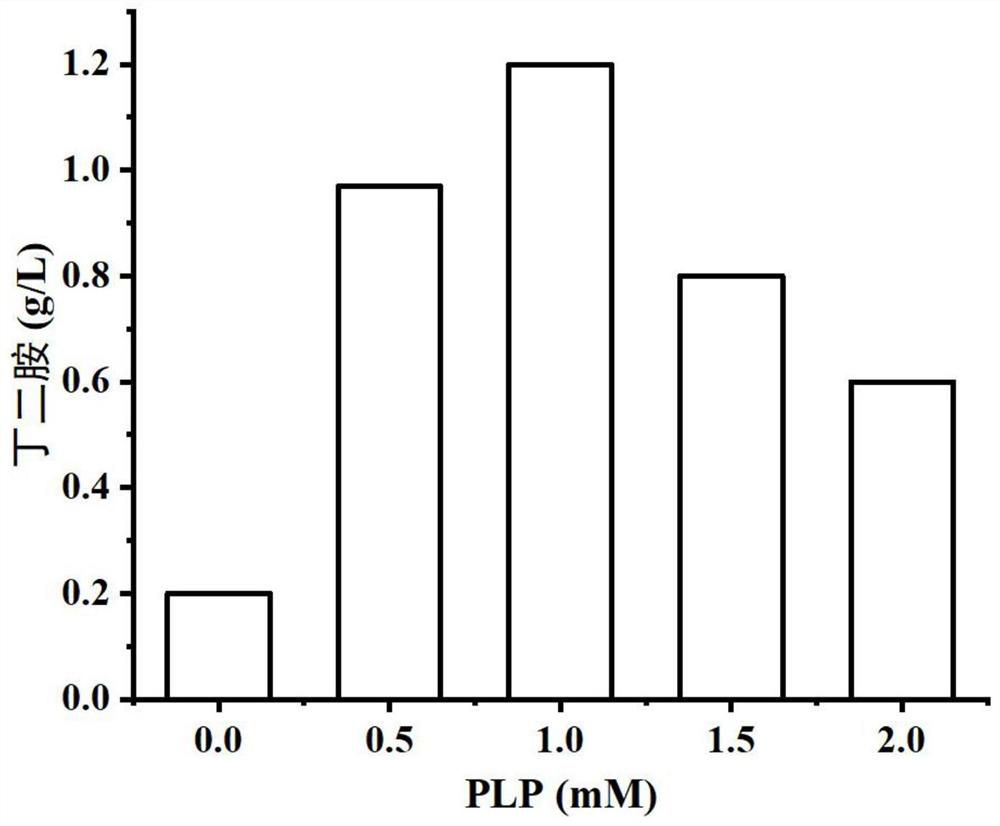

[0099] Embodiment 3 cultivates ornithine decarboxylase engineering bacteria

[0100] Cultivate genetically engineered bacteria expressing ornithine decarboxylase: pick a single colony of genetically engineered bacteria expressing ornithine decarboxylase, inoculate it in LB medium, and culture it overnight at 37°C; then transfer the bacteria to LB medium, The inoculum size is 1% of the volume of LB medium, cultured to OD at 37°C 600 When the concentration is 0.4, add IPTG to a final concentration of 0.8mmol / L, culture overnight at 25°C, collect the bacteria by centrifugation and crush to obtain a crude enzyme solution of ornithine decarboxylase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com