Manufacturing method of red mud ceramic product

A production method and ceramic technology, applied in ceramic products, ceramic material production, clay products, etc., can solve the problems of consuming manpower and material resources, red mud occupying storage space, etc., to avoid pollution, avoid waste of manpower and material resources, and realize the utilization of waste materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

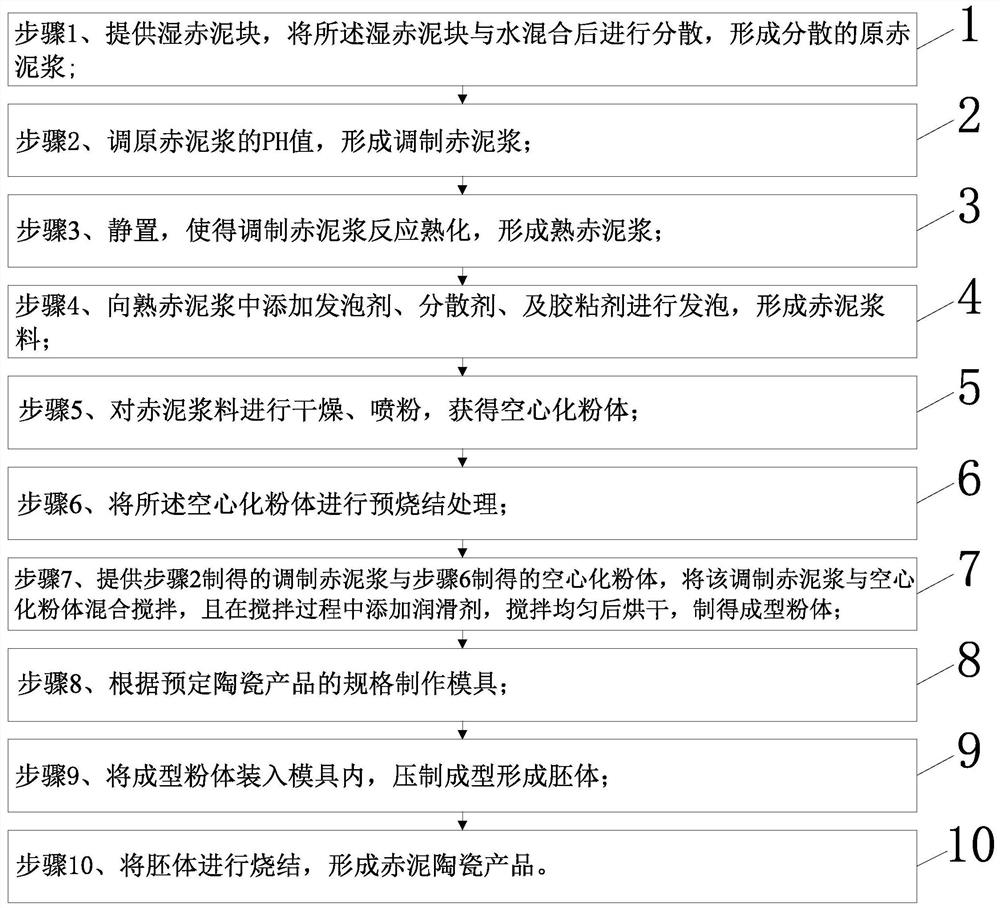

[0029] see figure 1 , the invention provides a method for making a red mud ceramic product, comprising the steps of:

[0030] Step 1, providing wet red mud lumps, mixing the wet red mud lumps with water and then dispersing to form dispersed raw red mud slurry;

[0031] Specifically, in the wet red mud lump, the particle size of the red mud powder is below 200 nanometers; the weight ratio of the wet red mud lump to water is 1:1˜0.5:1.

[0032] Specifically, in the step 1, ball milling is used to disperse the mixed wet red mud lumps and water to obtain raw red mud slurry.

[0033] Specifically, the pH value of the raw red mud slurry is 9-12.

[0034] Step 2, adjusting the pH value of the original red mud slurry to form a modulated red mud slu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com