Method for preparing NH4PbIxCl3-x perovskite photoelectric material by grinding

An optoelectronic material, perovskite technology, applied in chemical instruments and methods, lead compounds, inorganic chemistry, etc., can solve the problems of complex process, hinder the commercialization of perovskite solar cells, etc., and achieve a simple process and reduce the preparation cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

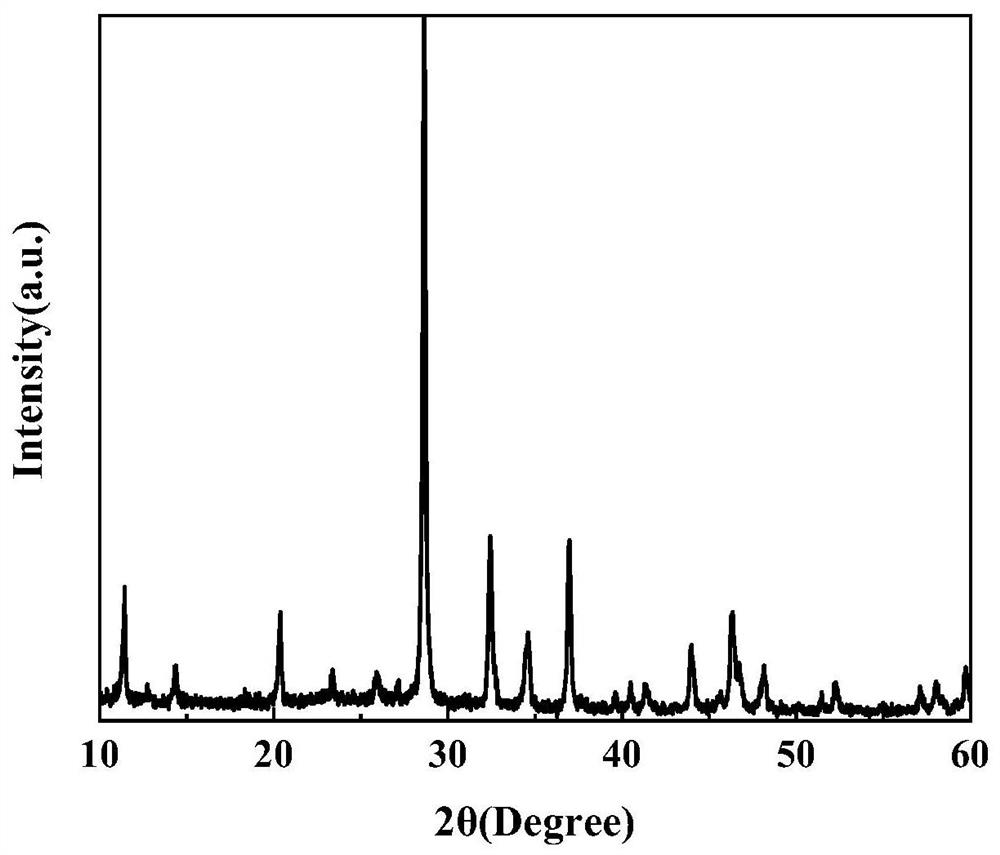

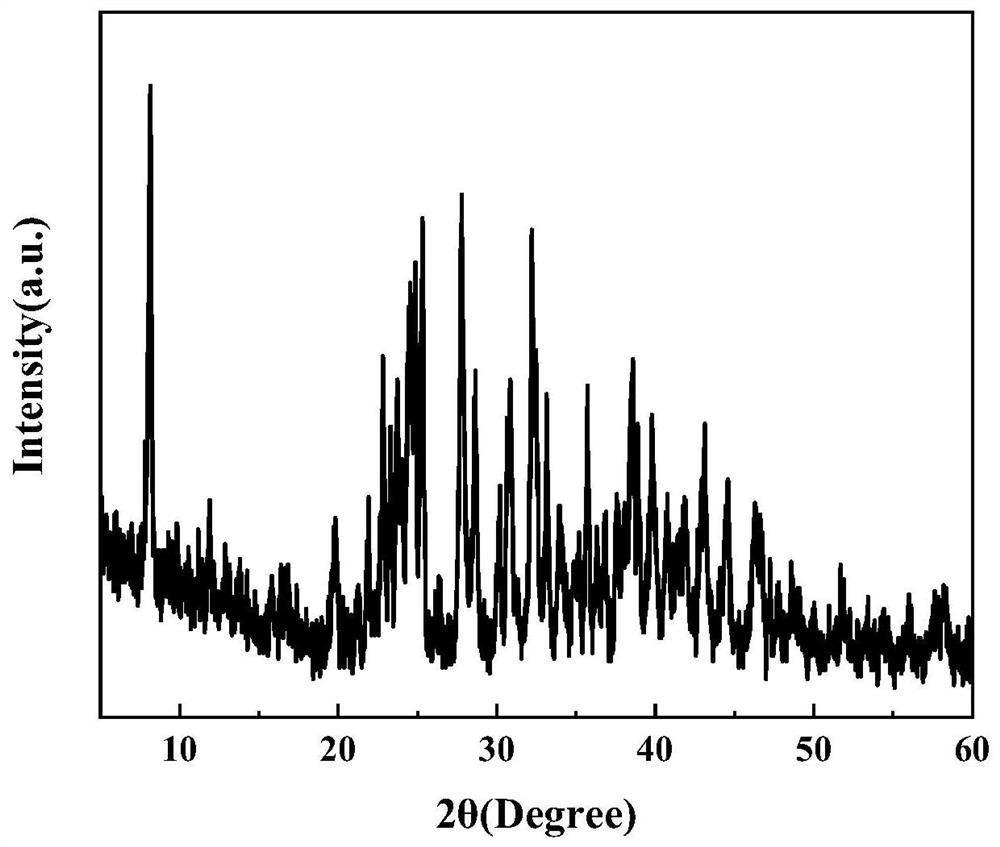

[0032] Step 1: Mix ammonium chloride and lead iodide in a molar ratio of 1:1 and put them into a ball mill for full grinding for 1 hour;

[0033] Step 2: Put the fully ground mixture into a vacuum oven and heat at 100°C for 1 hour, then cool to room temperature to obtain NH 4 PB x Cl 3-x Perovskite optoelectronic materials.

Embodiment 2

[0035] Step 1: Mix ammonium chloride and lead iodide in a molar ratio of 2:1 and put them into a ball mill for full grinding for 1 hour;

[0036] Step 2: Put the fully ground mixture into a vacuum oven and heat at 150°C for 3 hours, then cool to room temperature to obtain NH 4 PB x Cl 3-x Perovskite optoelectronic materials.

Embodiment 3

[0038] Step 1: Mix ammonium chloride and lead iodide in a molar ratio of 3:1 and put them into a ball mill for full grinding for 1 hour;

[0039] Step 2: Put the fully ground mixture into a vacuum oven and heat at 200°C for 1 hour, then cool to room temperature to obtain NH 4 PB x Cl 3-x Perovskite optoelectronic materials.

PUM

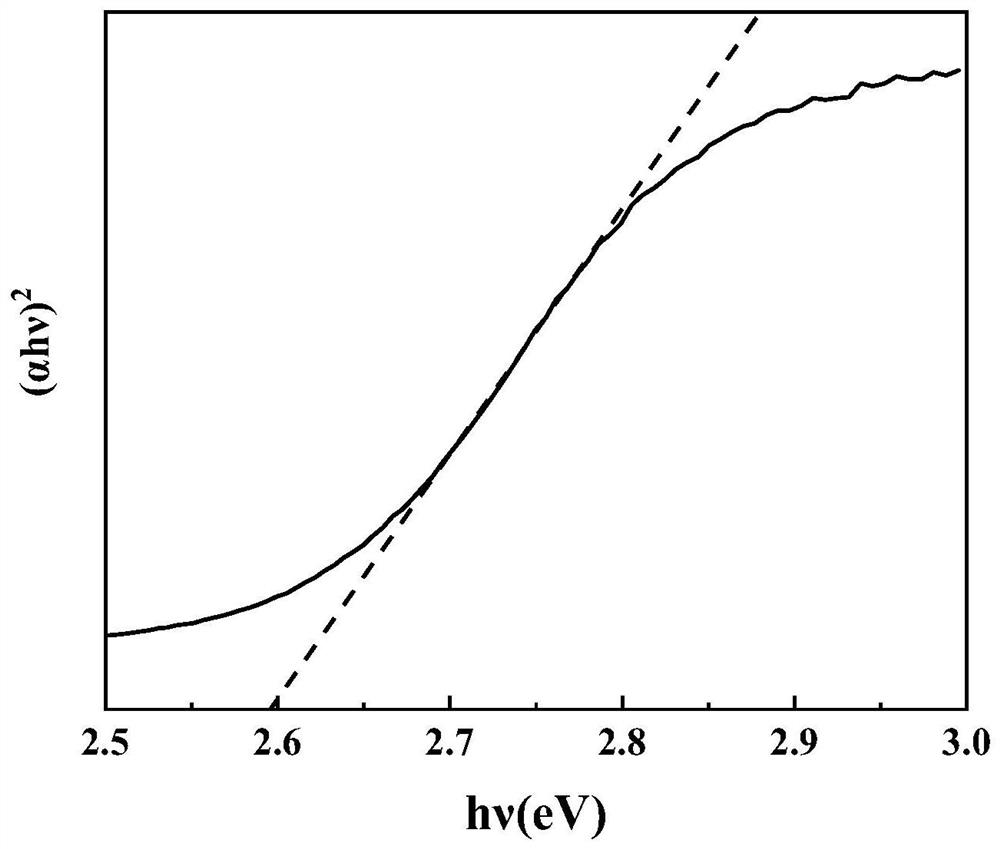

| Property | Measurement | Unit |

|---|---|---|

| optical band gap | aaaaa | aaaaa |

| optical band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com