Transfer device for reactor in power transformation system and method

A technology of transfer device and reactor, which is applied in the direction of winch device, transportation and packaging, lifting equipment braking device, etc., can solve the problems of saving transfer device and manpower, disadvantages, etc., and achieve high support and fixation accuracy, high transfer efficiency, The effect of ensuring the stability of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

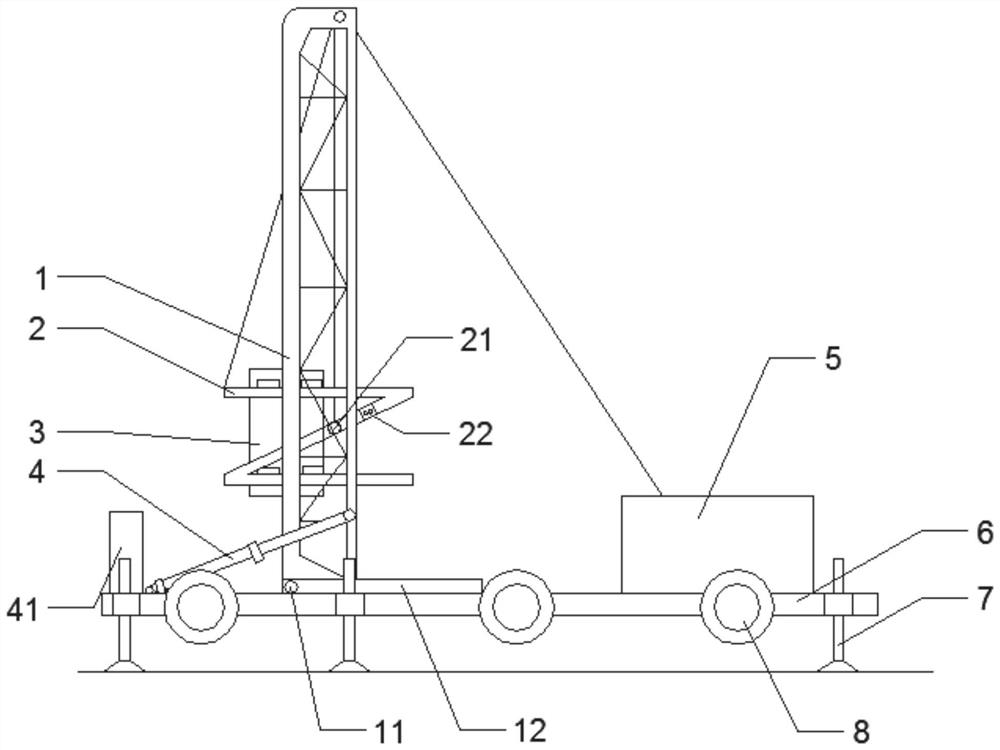

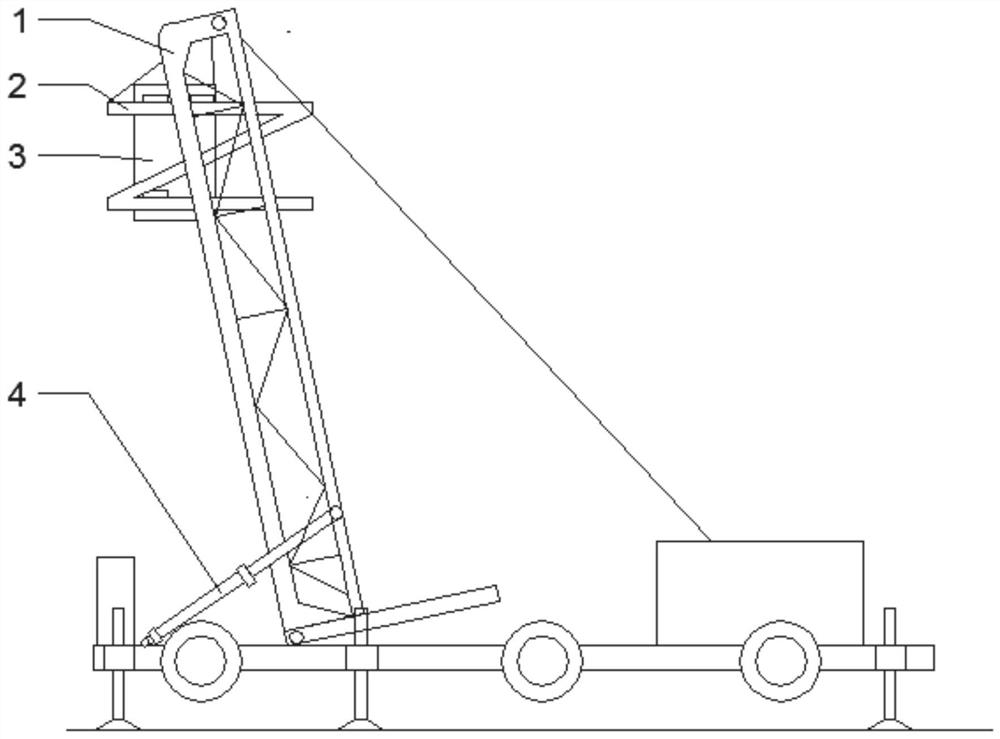

[0030] A transfer device for a reactor in a substation system, characterized in that it includes a support connected to a base, an overturning system and a lifting system;

[0031] The support 1 is slidingly connected to the rotating shaft of the Z-shaped bracket 2. The Z-shaped bracket 2 includes an upper strut and a lower strut, and the two struts can support the supporting part on the side of the reactor. The Z-shaped bracket The frame 2 supports the reactor 3 to move up and down and rotate in the chute of the bracket 1; the lifting system includes a winch 5 machine and a steel wire rope, and the steel wire rope goes around the top of the bracket to connect with the Z-shaped bracket; the turning system includes a turning shaft 11, the The support 1 is rotationally connected with the base 6 through the turning shaft 11, the turning shaft 11 passes through the bottom of the support 1 and is located on one side of the support 1, and the other side of the support 1 is rotational...

Embodiment 2

[0037] The support 1 is slidingly connected to the rotating shaft of the Z-shaped bracket 2. The Z-shaped bracket 2 includes an upper strut and a lower strut, and the two struts can support the supporting part on the side of the reactor. The Z-shaped bracket The frame 2 supports the reactor 3 to move up and down and rotate in the chute of the bracket 1; the lifting system includes a winch 5 machine and a steel wire rope, and the steel wire rope goes around the top of the bracket to connect with the Z-shaped bracket; the turning system includes a turning shaft 11, the The support 1 is rotationally connected with the base 6 through the turning shaft 11, the turning shaft 11 passes through the bottom of the support 1 and is located on one side of the support 1, and the other side of the support 1 is rotationally connected with one end of the hydraulic push rod 4, and the hydraulic push rod 4 The other end is rotatably connected with the base 6 .

[0038]It also includes a walking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com