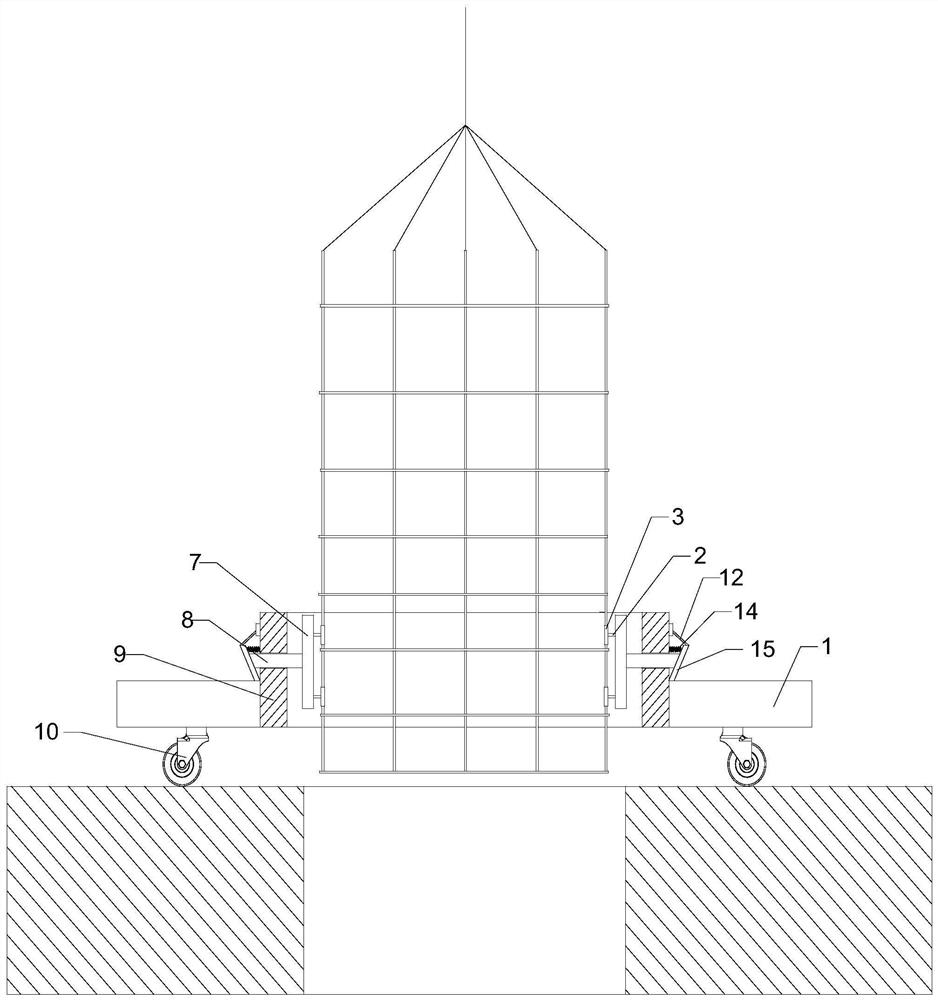

Hoisting device for prefabricated reinforcement cage

A hoisting device and steel cage technology, which is applied in transportation and packaging, load hanging components, construction, etc., can solve problems such as collapsed holes, long construction period, and deformation of the steel cage size, and achieve the effect of increasing the bearing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

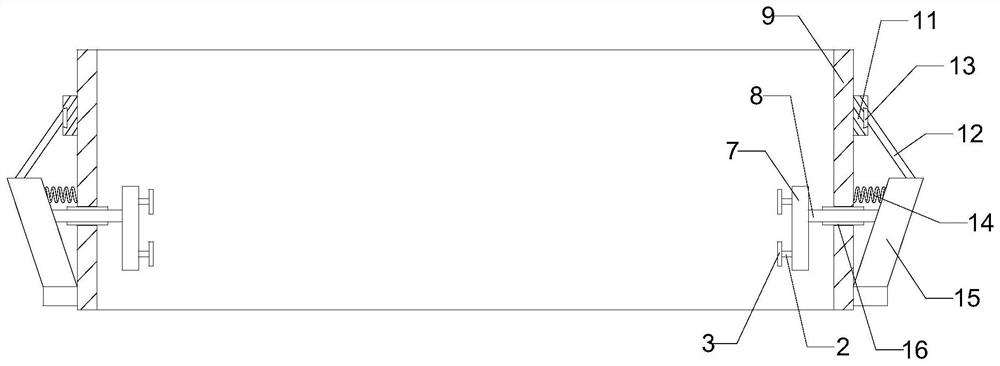

[0033] Such as Figure 1-8 As shown, this embodiment includes a sleeve I9, a plurality of bearing plates 1 are provided on the outer peripheral wall of the sleeve I9 along the circumferential direction of the sleeve I9, There are a plurality of vertical plates 7 on the inner wall of the vertical plate 7, and a rectangular groove I17 is opened on the side wall of each vertical plate 7 away from the sleeve I9, and a rectangular groove I17 is provided on the bottom of the rectangular groove I17 along the axial direction of the sleeve I9. There are two baffles 23, and the upper and lower ends of each baffle 23 are provided with ribs 20 with a semicircular cross section, and the arc-shaped surface of each rib 20 is opposite to the inner wall of the rectangular groove I17 , arc-shaped slots I are provided on the arc-shaped surfaces of the upper and lower ends of each rib 20 along the horizontal direction, and rectangular slots II are provided on the two side walls of each baffle p...

Embodiment 2

[0036] Such as Figure 1-8 As shown, this embodiment makes the following further limitations on the basis of Embodiment 1: This embodiment includes a plurality of limit rings I27 in the clamping assembly, and the groove bottom of the slider 21 away from the rectangular groove I17 There is a through hole I on the end surface of the upper part, and a push rod 28 is movable in the through hole I, and both ends of the push rod 28 are movable through the through hole I and then protrude from the through hole I. 21 A sleeve II30 is provided on the end surface of the groove bottom away from the rectangular groove I17, and the sleeve II30 is coaxial with the through hole I, and a spring is arranged on the inner wall of the through hole I near the bottom of the rectangular groove I17. I37, a limit ring I27 is connected to the outer wall of the extension end of a push rod 28, the limit ring I27 is connected to the spring I37, and a rotating shaft 36 is provided to rotate in the sleeve I...

Embodiment 3

[0041] Such as Figure 1-8 As shown, this embodiment makes the following further limitations on the basis of Embodiment 1: In this embodiment, along the circumferential direction of the sleeve I9, on the outer wall of the sleeve I9, there are a plurality of vertical plates 7 corresponding to each other. There are through holes II in each through hole II, and a push rod 8 is movable in each through hole II. Along the circumferential direction of the sleeve I9, on the outer wall of the lower end of the sleeve I9, a plurality of limiters corresponding to the through holes II are hinged. The position plate 15 is provided with a spring II14 on the outer wall of each push rod 8, one end of the spring II14 is connected to the outer wall of the sleeve I9, and the other end of the spring II14 is connected to the side of the limit plate 15 One end of the push rod 8 is connected to the vertical plate 7, the other end of the push rod 8 is hinged to the side wall of the limit plate 15, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com