Improved formed part sheet machining technology

A processing technology and improved technology, applied in the field of improved forming parts sheet processing technology, can solve problems such as affecting production quality and production efficiency, forming shapes easily damaged and collapsed edges, and difficult to control processing quality, so as to increase product competitiveness. , The effect of improving product profit and stable processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with examples and specific implementation methods.

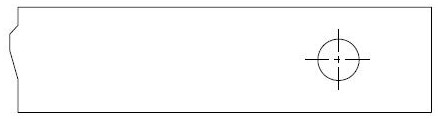

[0027] Such as Figure 2-1~2-3 As shown, the improved processing technology for forming thin slices, the processing technology includes the following process steps:

[0028] 1) Combine and process the formed part 1, use Mitsui surface grinder, select SDC-120 grinding wheel, the speed of the grinding wheel is 3000mm / min, the feed rate is 0.002, and carry out rough grinding of the shape; according to the design size, the width of the shape of the formed part 1 is 3 Grinding and finishing with length 4, use Mitsui surface grinder, select SDC-500 grinding wheel, grinding wheel speed 3000mm / min, feed rate 0.001; process positioning hole 5, use Charmilles 2030 wire cutting discharge, discharge in five times Electric discharge cutting, the speed is 0.3mm / min, 0.5mm / min, 0.7mm / min, 5mm / min, 5mm / min;

[0029] 2) Process the head forming part 2 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com