Automatic detection method and device for cold finish extrusion machining of screw shaft

An automatic detection device and automatic detection technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of lack of processing and automatic production line technology for quality inspection, and achieve the effects of stabilizing processing quality, reducing costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

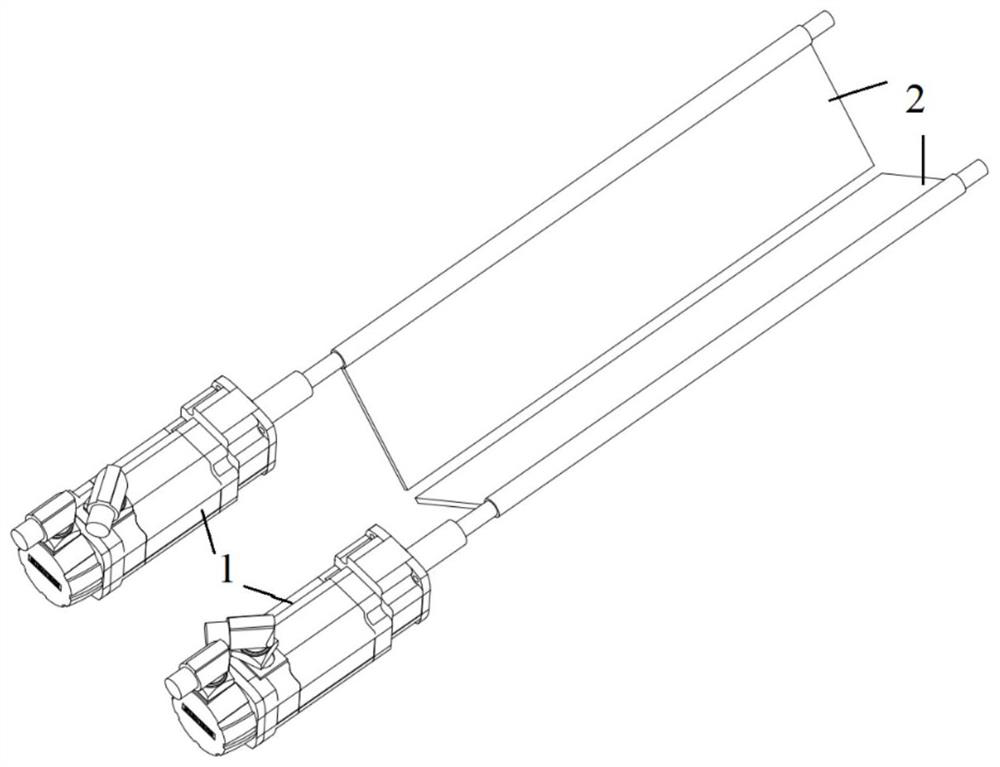

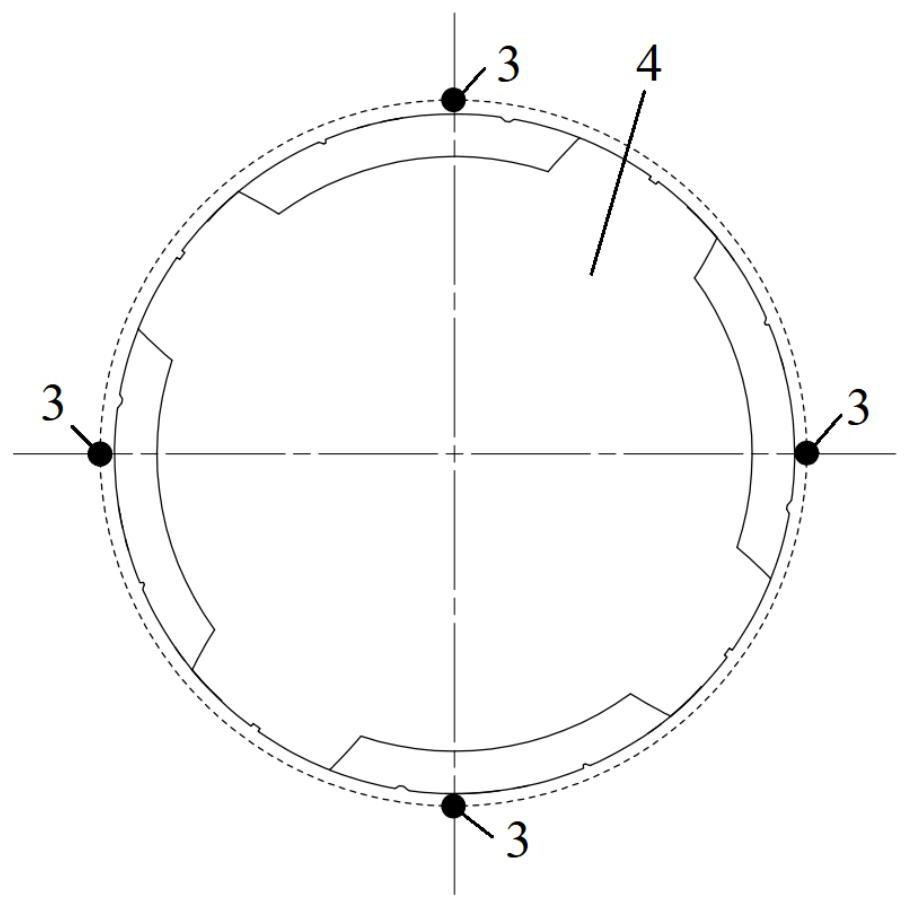

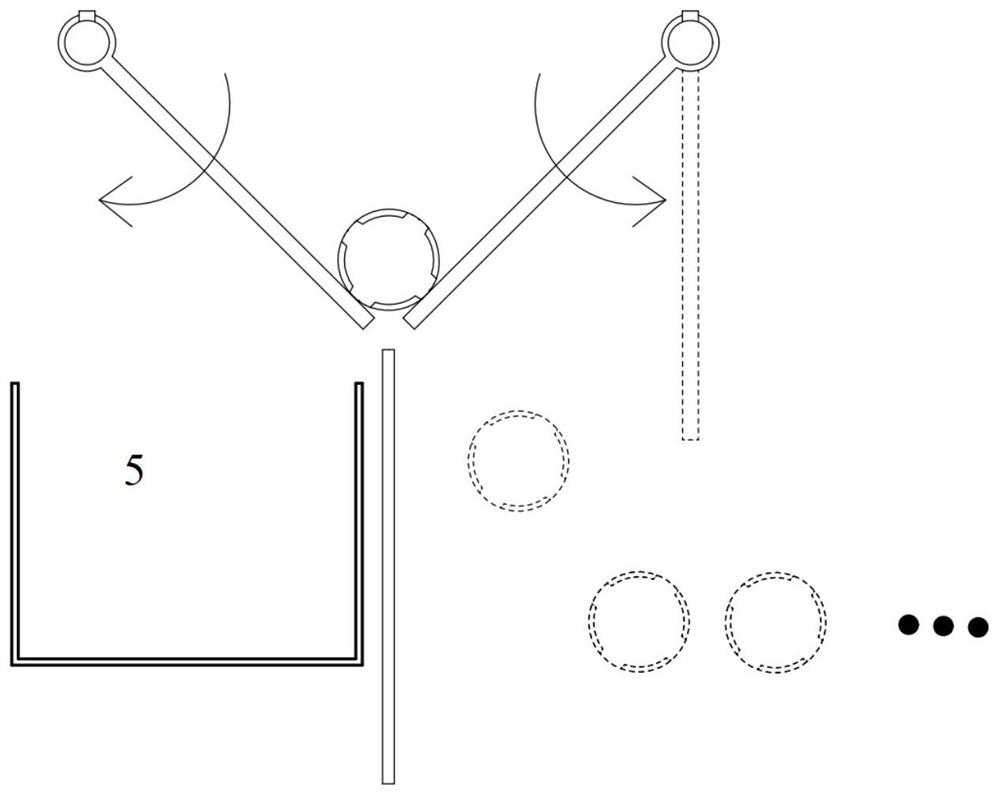

[0028] exist figure 1 and Figure 4 In the schematic diagram of the present invention shown, two servo motors 1 are respectively connected to the corresponding side plates 2, there is a gap between the lower parts of the two side plates, and the two side plates form a V-shaped groove. The rotation angle of the side plates is controlled by the servo motor to ensure that the two side plates can reach the same position after each rotation. The laser beam emitting device 6 and the laser beam receiving device 7 are placed at both ends of the screw shaft. The laser beam emitting device is composed of four uniformly distributed laser beam emitters, and the laser beam receiving device is composed of uniformly distributed four laser beam receivers. The front end of the laser beam receiver of the laser beam receiving device is provided with a nut 8, and the aperture of the central hole of the nut can be smaller than the laser spot diameter of the laser beam receiver of the laser beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com