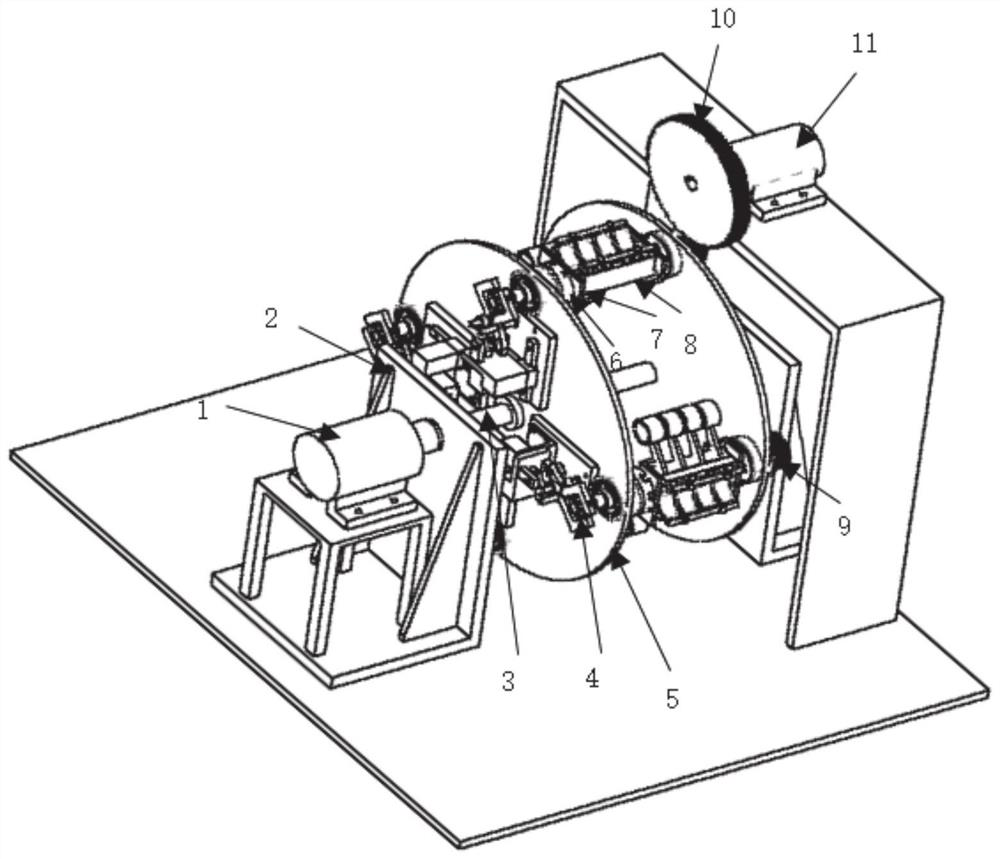

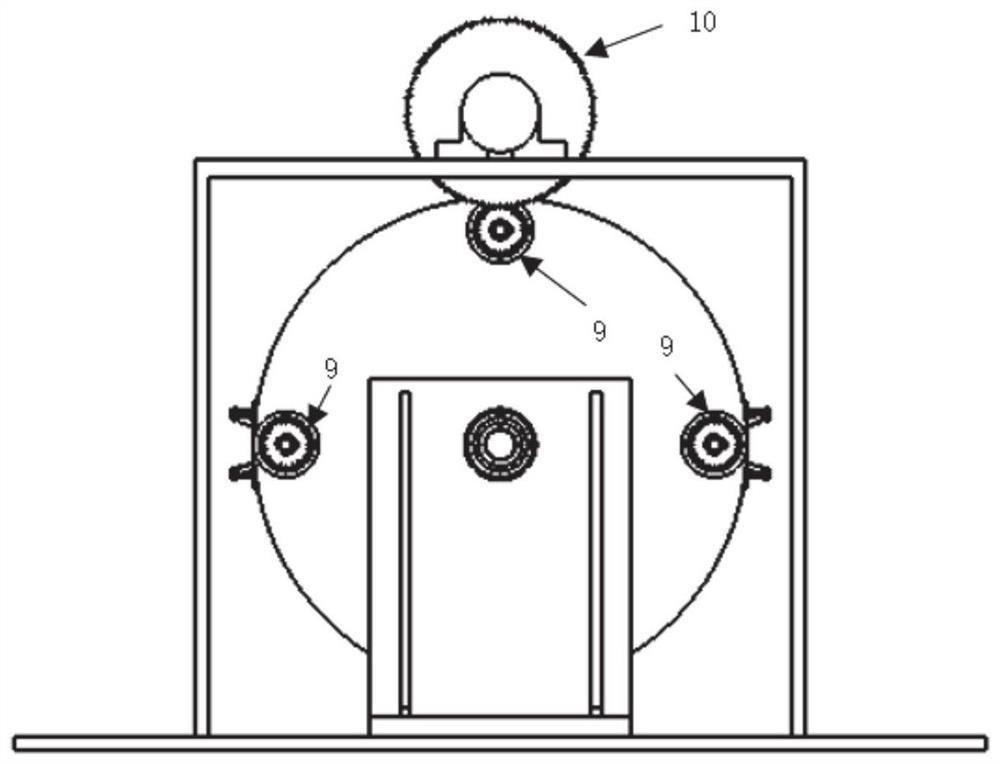

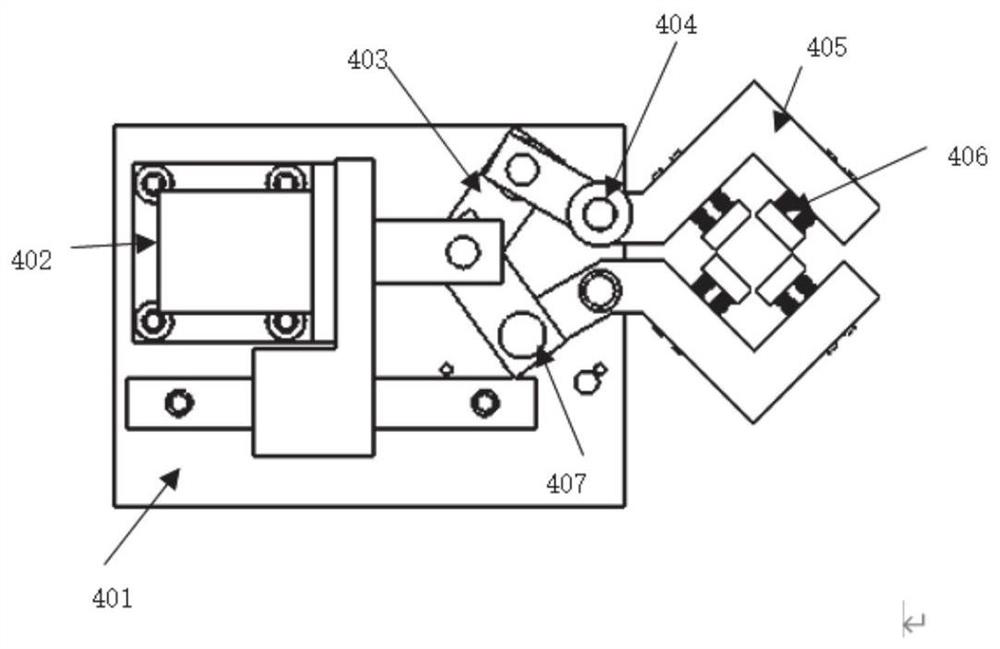

A jig and method for high-speed laser cladding remanufacturing of engine connecting rods

A technology of engine connecting rod and laser cladding, which is applied in the direction of manufacturing tools, laser welding equipment, metal processing equipment, etc., can solve the problems of difficult to control the surface roughness and dimensional accuracy of the coating, the weakening of the strength of parts, and the deformation and loss of the inner hole of the big end of the connecting rod. Problems such as roundness can be solved, and the motion transmission can be stable and reliable, the position of the connecting rod can be accurate, and the follow-up processing can be simplified.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] It should be pointed out that the following detailed description is exemplary and intended to provide further explanation to the present application. Unless defined otherwise, all technical and scientific terms used herein have the same meaning as commonly understood by one of ordinary skill in the art to which this application belongs.

[0043] For the convenience of description, if the words "up", "down", "front" and "rear" appear in the present invention, it only means that it is consistent with the directions of up, down, front and back of the drawings themselves, and does not limit the structure. It is for the convenience of describing the present invention and simplifying the description, but does not indicate or imply that the referred device or element must have a specific orientation, be constructed and operated in a specific orientation, and thus should not be construed as limiting the present invention.

[0044] As introduced in the background technology, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com