Internal expansion type automatic clamping device for yarn feeding pipe processing

A technology of clamping device and yarn feeding tube, which is applied in the direction of workpiece clamping device, manufacturing tool, chuck, etc., can solve the problems such as surface damage of yarn feeding tube, avoid damage, adjust the internal expansion force, ensure The effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

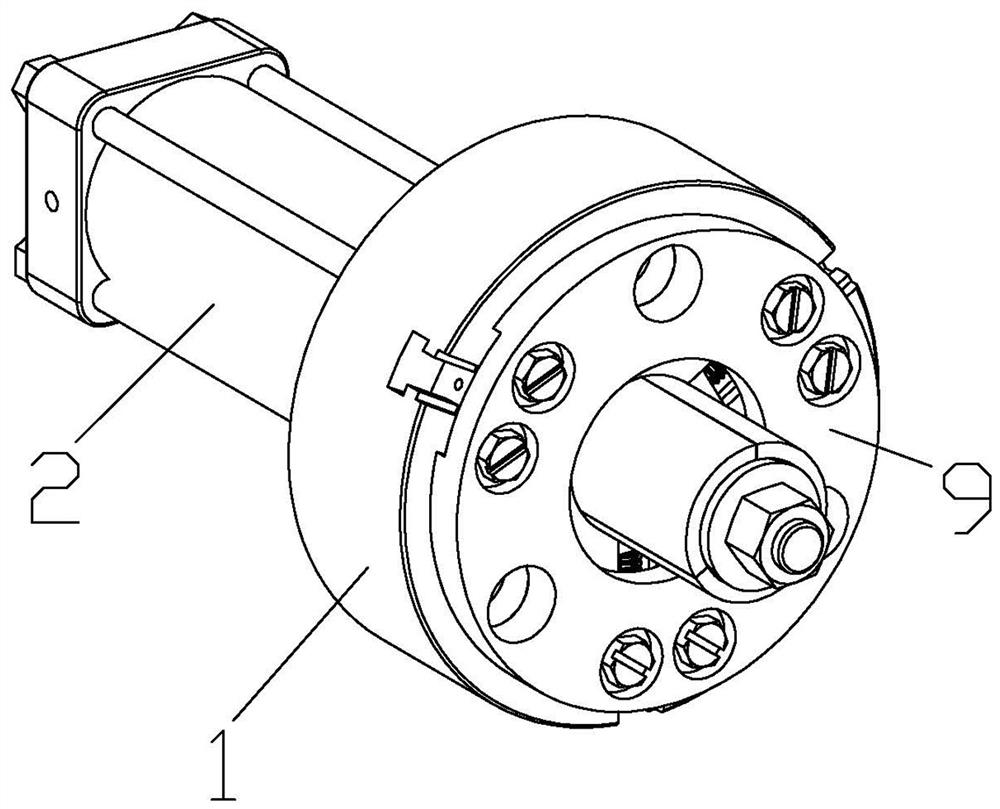

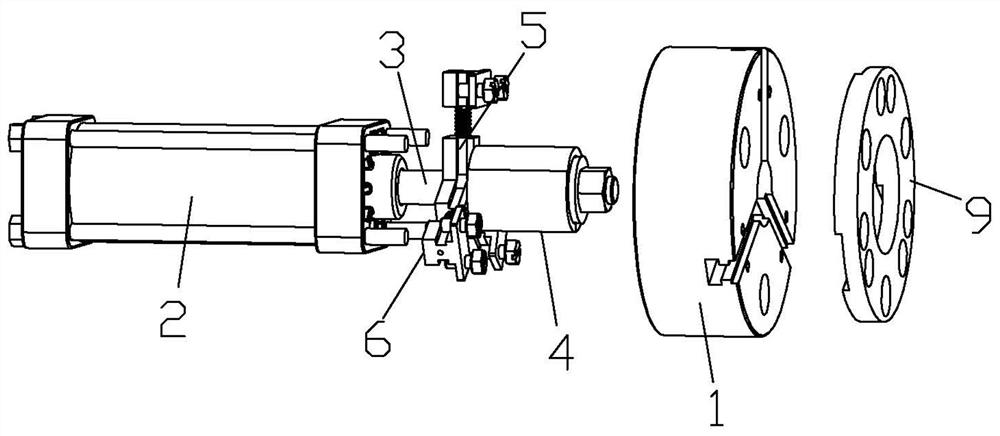

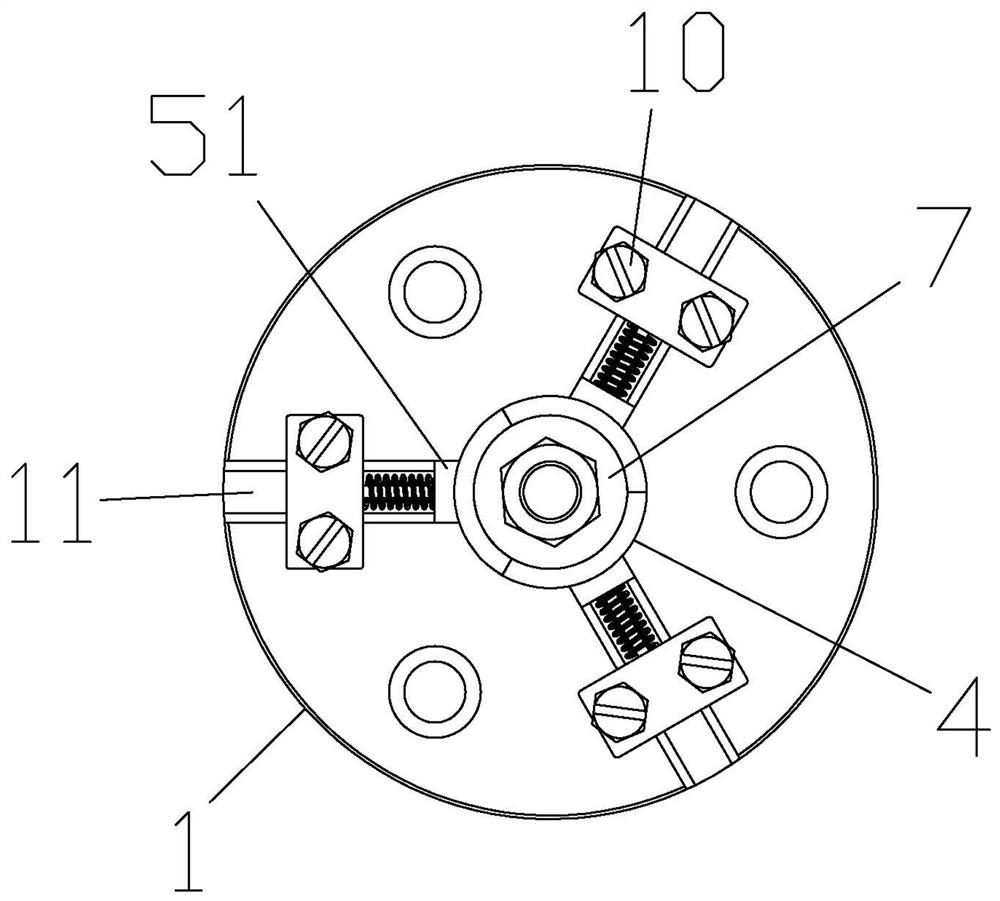

[0030] Refer to attached Figure 1-7 : This internal expansion type yarn feeding tube processing automatic clamping device includes a chuck 1, a driver 2, a guide rod 3, a clamping unit 4, a moving unit 5 and a limiting unit 6, a moving unit 5 and a limiting unit 6 The number of the three is equal and there are at least three. The driving member 2 is arranged on the chuck 1 and is used to drive the guide rod 3 to move linearly along its axis. One end of the guide rod 3 has a top-opening member 7, and the clamping unit 4 is located The upper surface is also for the opening part 7 to be placed inside, and the clamping unit 4 is opened or closed by the opening part 7 when the guide rod 3 moves linearly, the moving unit 5 connects the clamping unit 4 and the chuck 1, and can be moved along the The radial linear movement of the chuck 1, the limit unit 6 connects the mobile unit 5 and the chuck 1, and exists in the path of the mobile unit 5 when the chuck 1 makes a radial linear mot...

Embodiment 2

[0039] Refer to attached Figure 8 , 9 : the first matching structure 51 is slidingly matched with the first guiding structure 11, and the first guiding structure 11 protrudes / recesses laterally along the left and right sides of the first matching structure 51, and the first matching structure 51 moves along the left and right sides of the first guiding structure 11. The lateral surface is concave / convex laterally. Considering that when the mobile unit 5 slides on the first guiding structure 11 through the first matching structure 51, the connection of the first matching structure 51 cannot be guaranteed by only relying on the friction force of the two, that is, it is easy to escape from the first guiding structure 11, Therefore, both of them realize anti-off by setting protrusion / depression or depression / protrusion structure on themselves. The protrusion here can be a round bump, and the depression can be a rectangular groove, so that the protrusion can be inserted into the ...

Embodiment 3

[0041] Refer to attached Figure 10 , 11 : the first matching structure 51 is slidingly matched with the first guiding structure 11, and the first guiding structure 11 protrudes / recesses laterally along the left and right sides of the first matching structure 51, and the first matching structure 51 moves along the left and right sides of the first guiding structure 11. The lateral surface is concave / convex laterally. Based on the purpose of Embodiment 2, the protrusion here can be a rectangular bump, and the depression can be a rectangular groove. Compared with the structure of Embodiment 2, the difference between the rectangular bump and the rectangular groove The contact surface between them is larger, so that the cooperation degree is higher, and the mobile unit 5 has a higher smoothness of movement like this.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com