Microwave heating resin sand core forming device and microwave heating resin sand core forming method

A resin sand core and microwave heating technology, which is applied to casting molding equipment, molds, cores, etc., can solve the problems of only 5-20 boxes/hour, core shooting failure, and low scrap rate, so as to improve the turnover rate and production efficiency, uniform heat curing, and shortened molding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

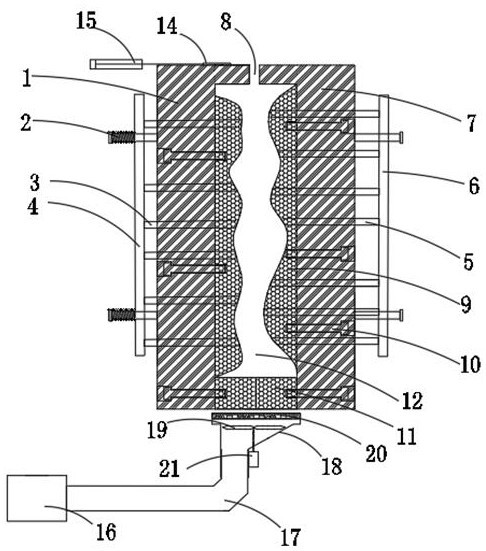

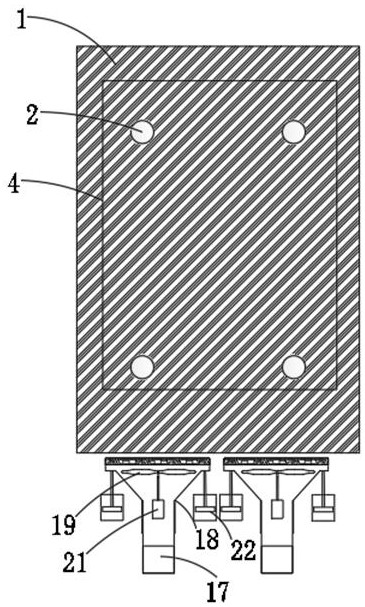

[0018] Embodiment: a kind of microwave heating resin sand core molding device, such as Figure 1-2 As shown, it includes fixed mold outer frame 1, fixed mold top plate 4, spring 2, fixed mold thimble 3, fixed mold top plate 4, movable mold ejector pin 5, movable mold ejector pin 5 plates, movable mold outer frame 7 and sand inlet hole 8 , the inner wall of the fixed mold outer frame 1 and the inner wall of the movable mold outer frame 7 are respectively provided with mold blocks 9 which form a cavity 12 with each other, and the mold blocks 9 have different shapes according to the different types of core boxes. The lower end of the inner wall of the fixed mold outer frame 1 and the lower end of the inner wall of the movable mold outer frame 7 are respectively provided with bottom movable blocks 11 that form a flat bottom surface with each other; the material of the mold movable block 9 and the bottom movable block 11 is ceramics The mold block 9 and the bottom block 11 made of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com