Concrete pumping pipeline blockage part detection device

A concrete pump and detection device technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of cumbersome operation, poor detection accuracy, and small application range, and achieve simplified operation and high accuracy High, the effect of improving the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

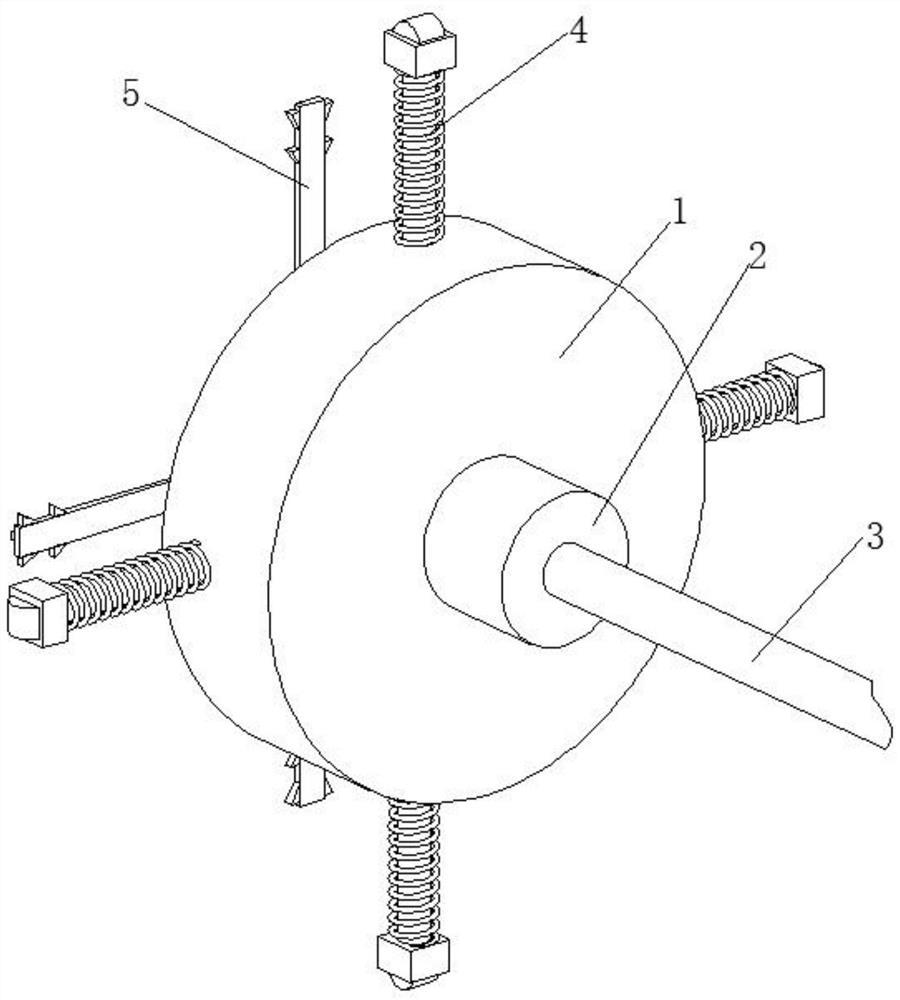

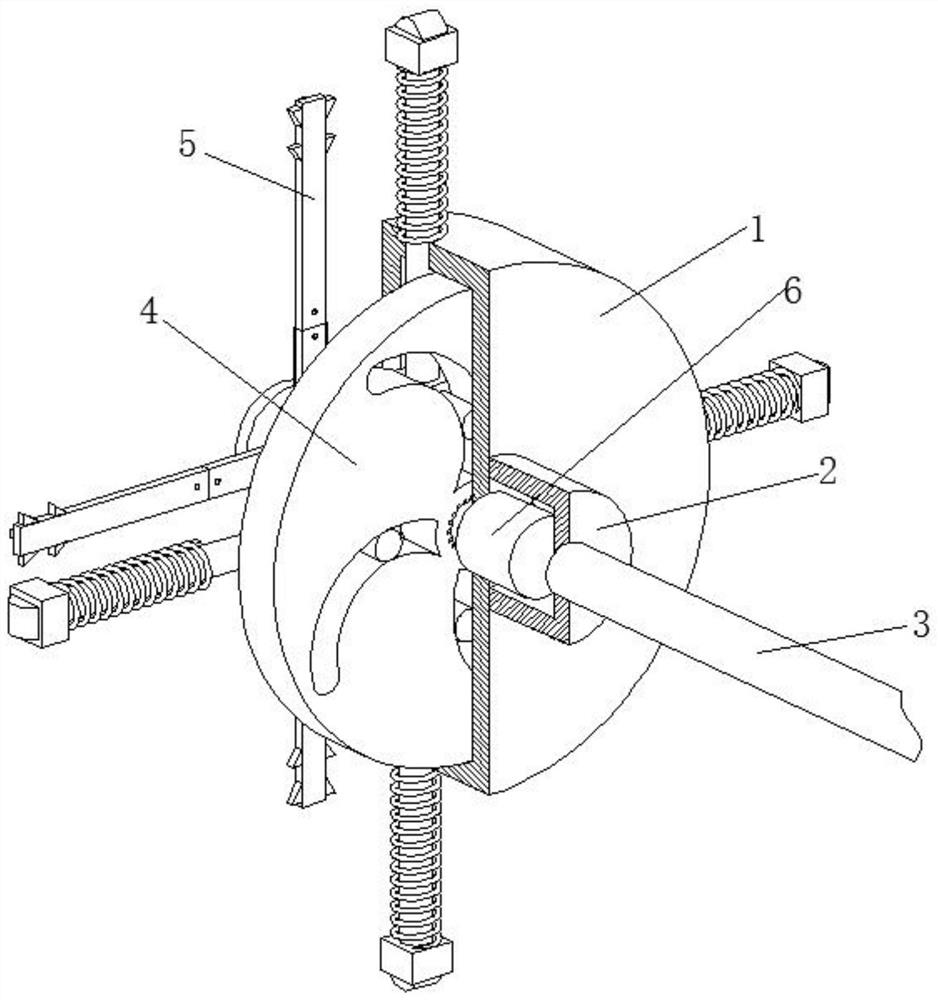

[0031] A concrete pumping pipeline blockage detection device, such as Figure 1-Figure 6 As shown, it includes a fixed plate 1, the right side of the fixed plate 1 is connected with a protective shell 2 by bolts, the right side of the protective shell 2 is connected with a connecting rod 3 by bolts, the inside of the fixed plate 1 is provided with an adjustment mechanism 4, and the fixed plate 1 A dredging mechanism 5 is provided on the left side of the plate, and a motor 6 is connected to the right side of the fixed plate 1 by bolts, and the motor 6 is located inside the protective shell 2 .

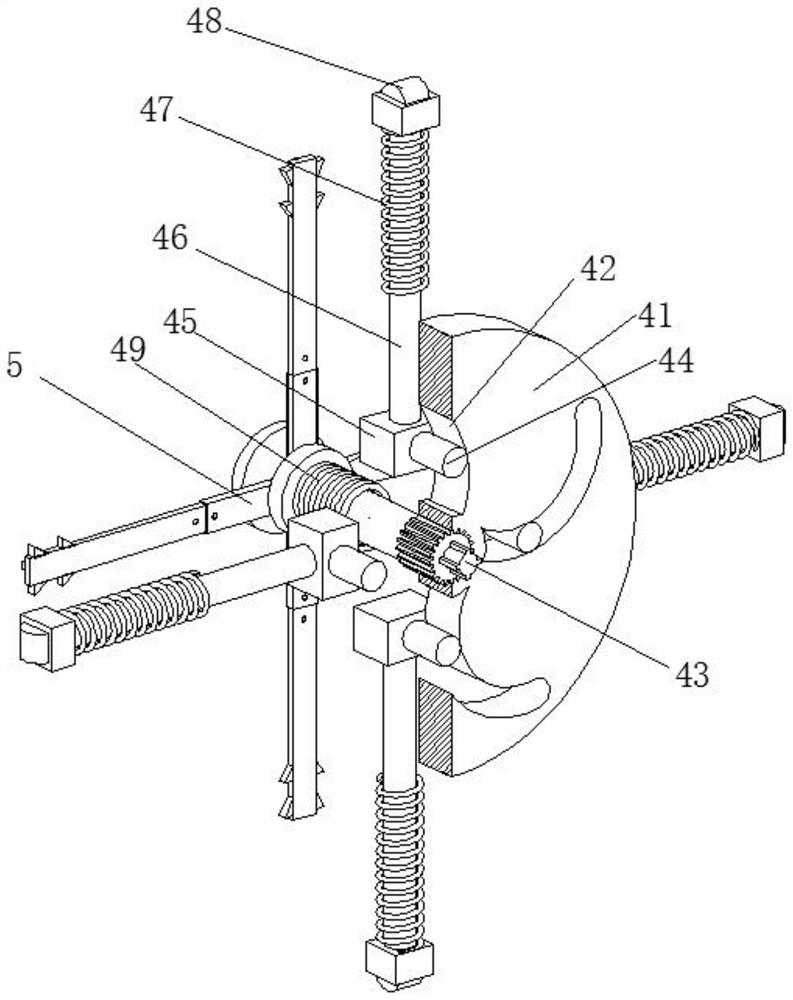

[0032] In this embodiment, the adjustment mechanism 4 includes a turntable 41, and four chutes 42 are arranged inside the turntable 41, and a transmission device 43 is arranged at the axis of the turntable 41, and the inner wall of the chute 42 is movably connected with a clamping rod 44, which The left end of bar 44 is welded with slide block 45, and the top of slide block 45 is welded...

Embodiment 2

[0042] Such as Figure 5-Figure 7As shown, on the basis of Embodiment 1, in this embodiment, the axis of the chuck 51 is welded and fixed to the left end of the sleeve 431, the right side of the chuck 51 is in contact with the left side of the supporting spring 49, and the supporting spring 49 will help the chuck 51 and the shaft sleeve 431 to reset after detecting the blocked part, preventing the motor 6 from driving the turntable 41 to rotate, and then causing the pulley block 48 to rotate inside the pipeline, causing damage to the device and causing the device to fail to continue to operate. Sex is greatly reduced.

[0043] It is worth noting that the crushing device 53 includes a fixed plate 531. Several positioning holes 532 are arranged inside the fixed plate 531. The inner walls of the positioning holes 532 are movably connected with screws 533. The crushing device 53 can remove smaller blockages in the pipeline. By crushing, it is possible to directly dredge the place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com