Work control method and device of cleaning equipment and cleaning equipment

A technology for cleaning equipment and work control, applied in the direction of cleaning action control, cleaning equipment, cleaning machinery, etc., can solve problems such as poor manual adjustment, and achieve the effect of solving poor manual adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

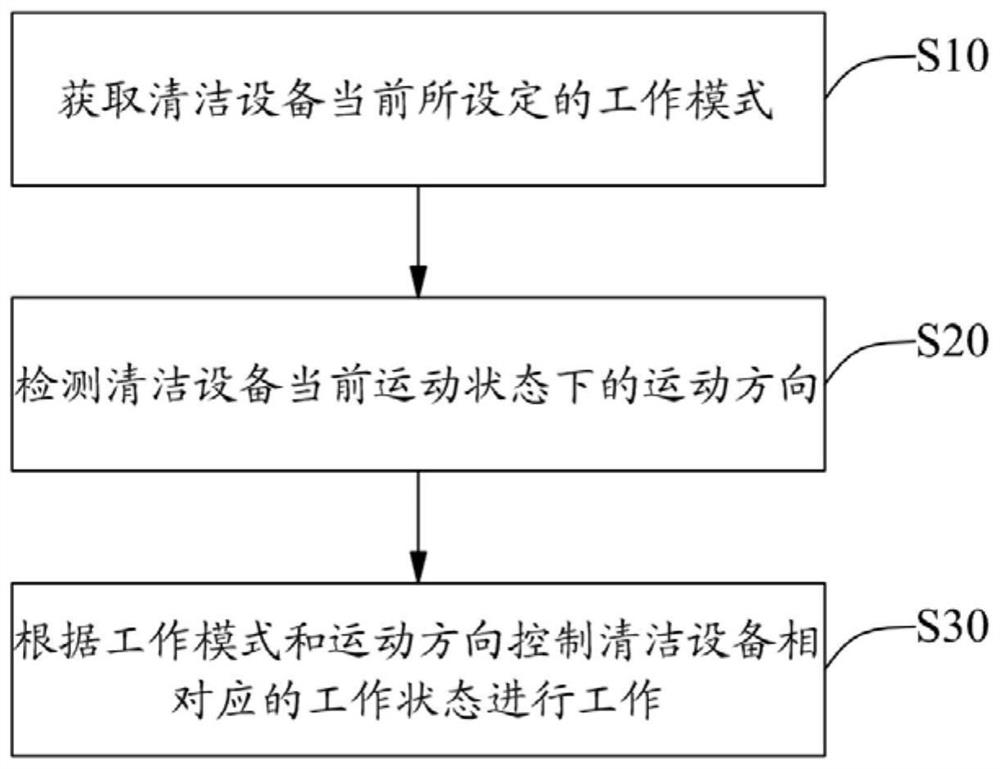

[0054] see figure 1 , is a schematic flowchart of the operation control method of the cleaning equipment provided by the first embodiment of the present invention. For the convenience of description, only the parts related to the embodiment of the present invention are shown. The operation control method of the cleaning equipment includes:

[0055] Step S10, obtaining the working mode currently set by the cleaning device;

[0056]Wherein, the work control method is applied to cleaning equipment, specifically, in this embodiment, the cleaning equipment is a washing machine, and the method is used to control the work of the washing machine. Wherein, the floor washing machine is provided with a traveling motor, a brush motor, a water absorbing motor and a lifting motor. Among them, the walking motor is used to drive the washing machine to move forward and backward; its brush motor is used to control the brush disc or brush head connected to it to work, so as to realize the scrub...

Embodiment 2

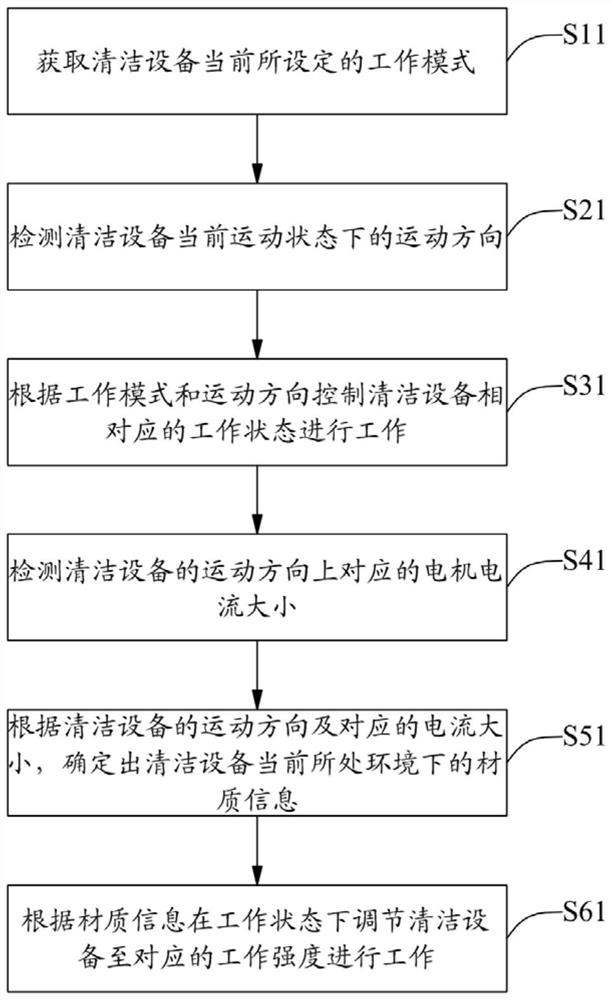

[0067] see figure 2 , is a schematic flow chart of a cleaning equipment operation control method provided by the second embodiment of the present invention. For the convenience of description, only the parts related to the embodiment of the present invention are shown. The operation control method includes:

[0068] Step S11, obtaining the working mode currently set by the cleaning device;

[0069] Wherein, in the embodiment of the present invention, the working mode includes a first working mode and a second working mode.

[0070] Step S21, detecting the movement direction of the cleaning device under the current movement state;

[0071] Wherein, in the embodiment of the present invention, the above-mentioned step of detecting the movement direction of the cleaning device under the current movement state includes:

[0072] The direction of movement of the cleaning device is determined according to the magnitude, direction and change trend of the acceleration detected by th...

Embodiment 3

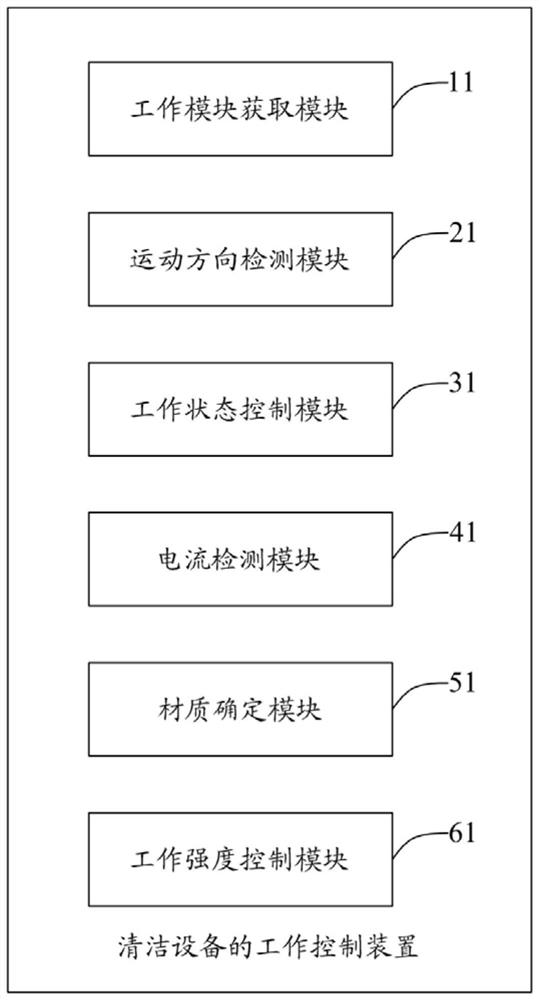

[0103] see image 3 , is a schematic structural diagram of the working control device of the cleaning equipment provided by the third embodiment of the present invention. For the convenience of description, only the parts related to the embodiment of the present invention are shown. The working control device of the cleaning equipment includes:

[0104] The working mode acquiring module 11 is used to acquire the working mode currently set by the cleaning device;

[0105] A motion direction detection module 21, configured to detect the motion direction of the cleaning device in its current motion state;

[0106] The working state control module 31 is configured to control the corresponding working state of the cleaning device to work according to the working mode and the moving direction.

[0107] Further, the working mode includes a first working mode and a second working mode;

[0108] Working state control module 31 comprises:

[0109] The first work control unit is confi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com