Transmission structure of mulching film recycling machine and mulching film recycling machine

A technology of transmission structure and recycling machine, which is applied in the field of agricultural machinery, can solve the problems of affecting agricultural production efficiency, affecting the service life of the machine, straw crushing and insufficient transmission efficiency, and shortens the power transmission distance, realizes long-distance transmission and transformation Direction, the effect of reducing the cost of manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

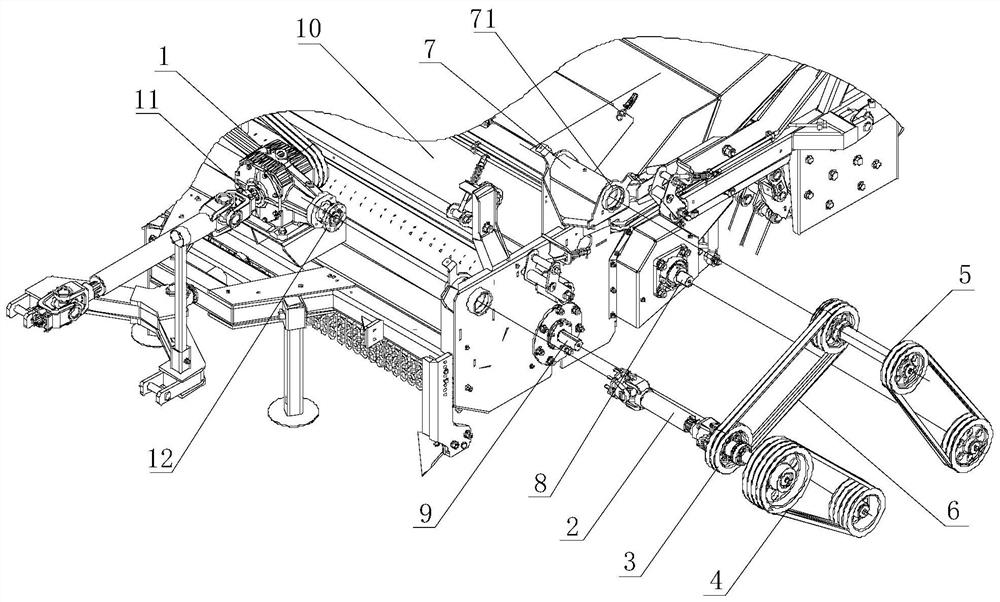

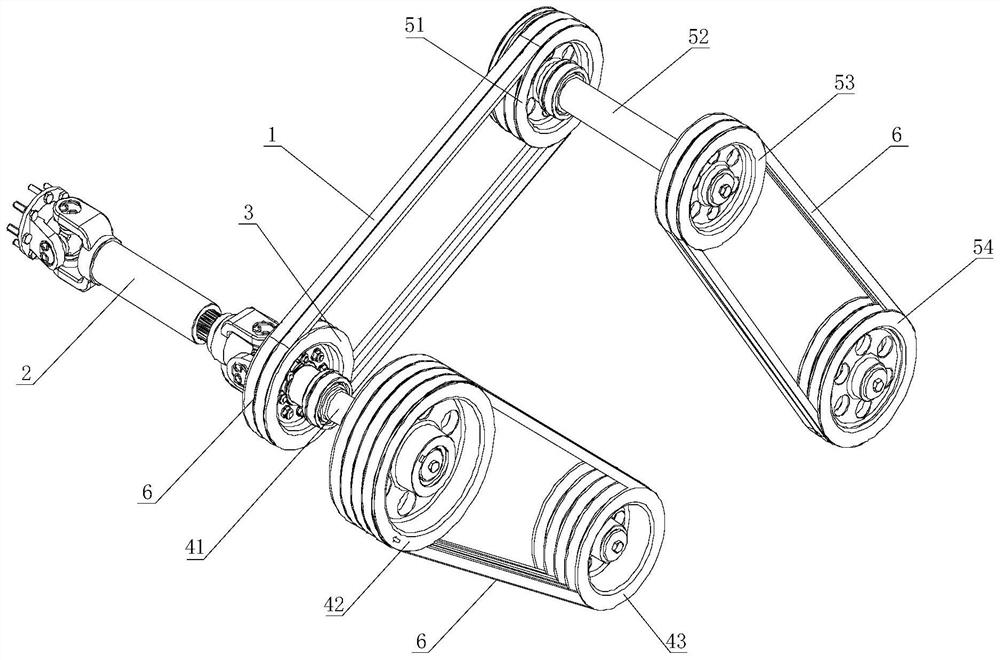

[0018] Such as figure 1 and figure 2 As shown, a transmission structure of a mulch recovery machine, the transmission structure is applied to the flailing drum mechanism 8 and the auger drum 9, including a bevel gear box 1 and a universal coupling 2, and the bevel gear box 1 includes a power input end 11 and a power output end 12, the power input end 11 is connected to the power source of the plastic film recycling machine 10, the power output end 12 is connected to one end of the universal coupling 2, and the universal coupling 2 The other end is provided with a first pulley 3, and the first pulley 3 is connected with a first transmission assembly 4 that drives the rotation of the auger drum 9, and a second transmission assembly 5 that drives the rotation of the knife drum mechanism 8, and The direction of rotation of the auger drum 9 and the knife drum mechanism 8 is the same.

[0019] The first transmission assembly 4 and the second transmission assembly 5 that are provi...

Embodiment 2

[0023] Such as figure 1 As shown, this embodiment also discloses a mulch recovery machine, which includes a knife throwing roller mechanism 8, an auger roller 9 and a transmission structure arranged between the knife throwing roller mechanism 8 and the auger roller 9, and the transmission structure adopts The transmission structure described in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com