Intelligent production scheduling method and device and computer storage medium

An intelligent, production line technology, applied in computing, manufacturing computing systems, instruments, etc., can solve problems such as time lag, mismatch between planning and execution, and inability to fully optimize business goals, so as to ensure matching and realize intelligent production scheduling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

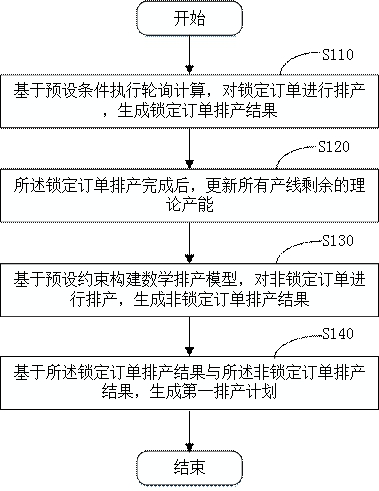

[0076] refer to figure 2 , figure 2 For the first embodiment of the intelligent production scheduling method of the present application, the method includes:

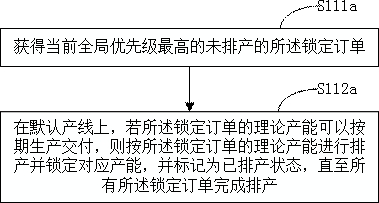

[0077] Step S110: Perform polling calculation based on preset conditions, schedule locked orders, and generate locked order scheduling results.

[0078] The preset condition can be that the theoretical capacity of the locked order meets production delivery, the theoretical capacity of the locked order cannot be produced and delivered on schedule, and the limit capacity of the locked order can be produced and delivered on schedule, if the theoretical capacity of the locked order and the limit capacity None of them can be produced and delivered on schedule, and the production line of the locked order can be replaced, if neither the theoretical capacity nor the limit capacity of the locked order can be produced and delivered on schedule, and the production line of the locked order cannot be replaced, etc. Wherein, the ...

no. 2 example

[0155] refer to Figure 9 , Figure 9 For the second embodiment of the intelligent production scheduling method of the present application, the method further includes:

[0156] Step S210: Perform polling calculation based on preset conditions, schedule locked orders, and generate locked order scheduling results.

[0157] Step S220: After the locked order scheduling is completed, update the remaining theoretical production capacity of all production lines.

[0158] Step S230: Construct a mathematical scheduling model based on preset constraints, schedule non-locked orders, and generate non-locked order scheduling results.

[0159] Step S240: Based on the scheduling result of the locked order and the scheduling result of the non-locked order, generate a first scheduling plan.

[0160] Step S250: Based on the first production scheduling plan, perform batch calculation to obtain a second production scheduling plan.

[0161] Compared with the first embodiment, the second embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com