Detection equipment for cable processing

A technology for testing equipment and cables, which is applied in the direction of testing material strength by applying stable bending force, testing material strength by applying stable tension/pressure, and measuring devices, which can solve problems such as poor practicability, low detection efficiency, and non-continuous use. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

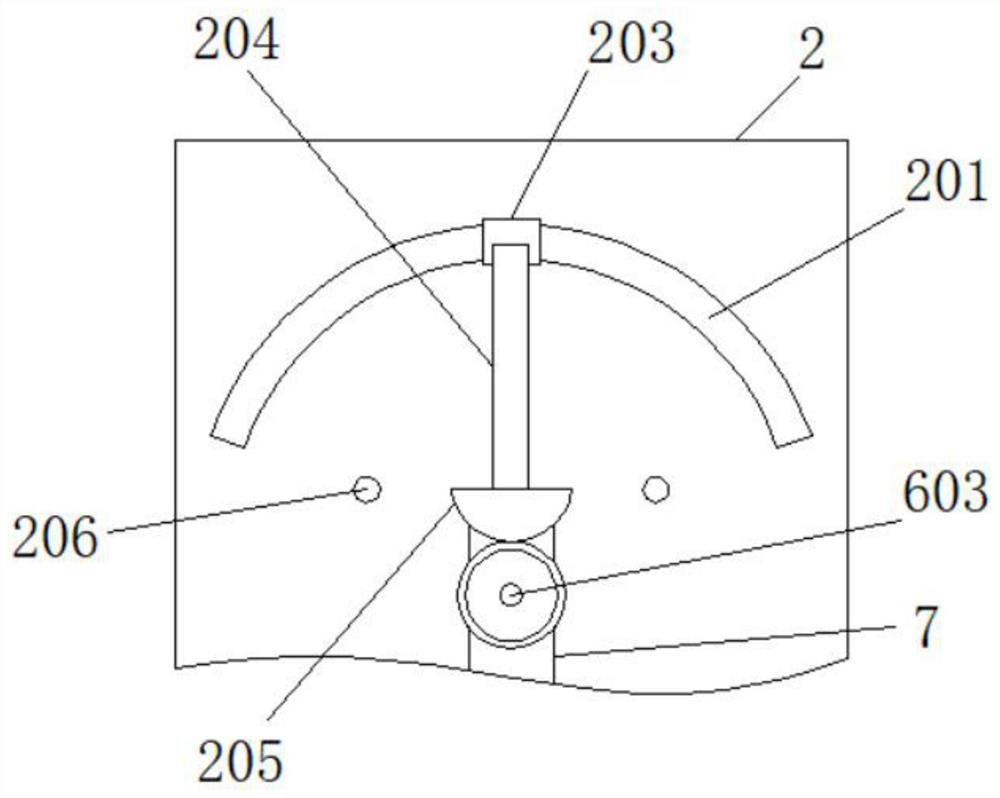

[0031] see Figure 1-6 , a detection device for cable processing, comprising a base 1, including a base 1 and a cable body 8, the top of the base 1 is respectively provided with a workbench 2 and a pay-off device 3, and the workbench 2 body is respectively provided with a No. 1 bushing 4, The top of the casing 5 and the No. 2 casing 6, the top of the pay-off device 3 is provided with a No. 1 fixed rod 301, the top of the No. 2 casing 6 is provided with a No. 2 fixed rod 601, and the top of the No. 1 fixed rod 301 is provided with a No. 1 gear 302, and the top of No. 2 fixed rod 601 is provided with No. 2 gear 602, No. 1 gear 302 and No. There is an arc-shaped chute 201, and the inside of the arc-shaped chute 201 is slidably connected with a slider 202, the top of the slider 202 is fixedly connected with a limit tube 203, and the top of the limit tube 203 is provided with an L-shaped plate 204, L-shaped The other end of the plate 204 is welded with a sector gear 205, and the s...

Embodiment 2

[0041] On the basis of Example 1, please refer to Figure 1-6 , a detection method for cable processing detection equipment, its use steps are as follows:

[0042] S1. First place the cable roller 305 on the base 304, pass the cable body 8 through the No. 1 casing 4, and use the laser sensor 406 to detect the surface smoothness and flatness of the cable body 8.

[0043] S2. Then the cable body 8 passes through the No. 2 through groove 503 on the left side of the box body 5 and enters the inside of the box body 5, so that the cable body 8 is covered on the surface of the guide wheel 502. By turning the No. 1 threaded rod 506, the pressure plate 507 compresses and limits the cable body 8 , and adjusts the height of the guide wheel 502 through the telescopic rod 501 , so as to detect the tensile capacity of the cable body 8 .

[0044] S3. When it is necessary to perform a breaking test on the cable body 8, move the cable body 8 from the inside of the box body 5 through the No. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com