Rotary kiln spray gun gas supply device

A technology of gas supply device and rotary kiln, which is applied in the direction of rotary drum furnace, furnace, lighting and heating equipment, etc. It can solve the problems of calcining defects of finished products and differences in gas components, achieve gas concentration balance, improve gas components, The effect of balanced air distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

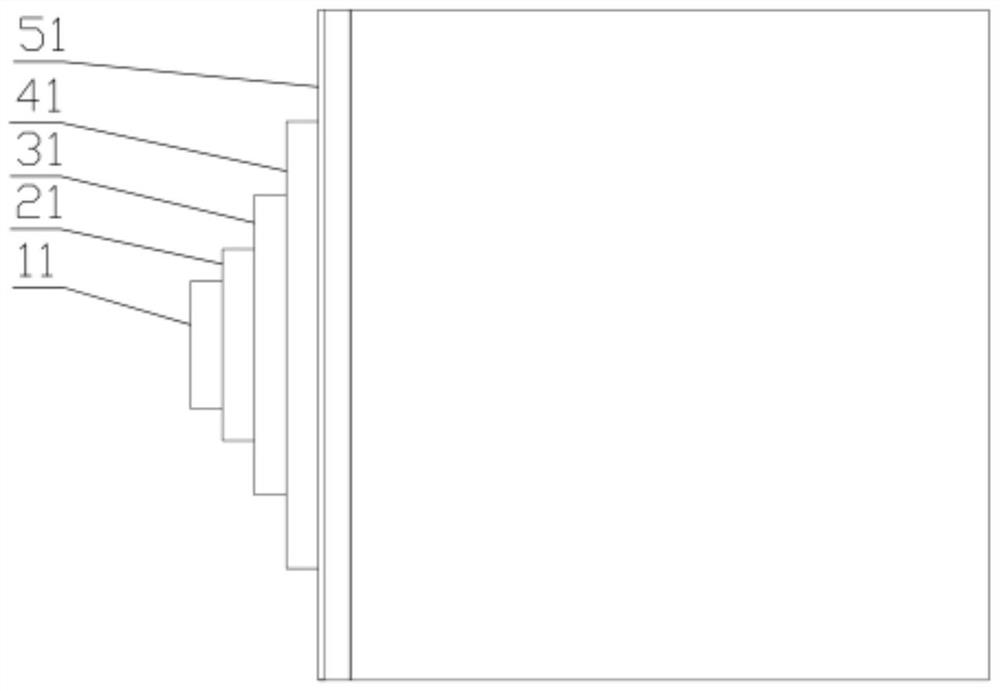

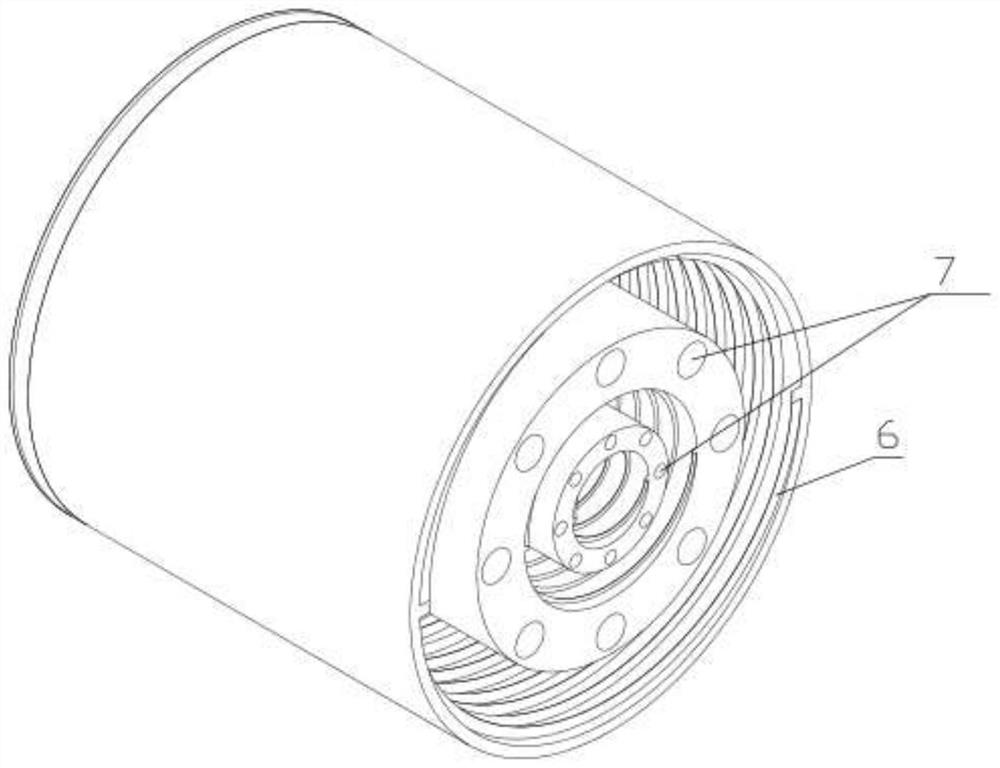

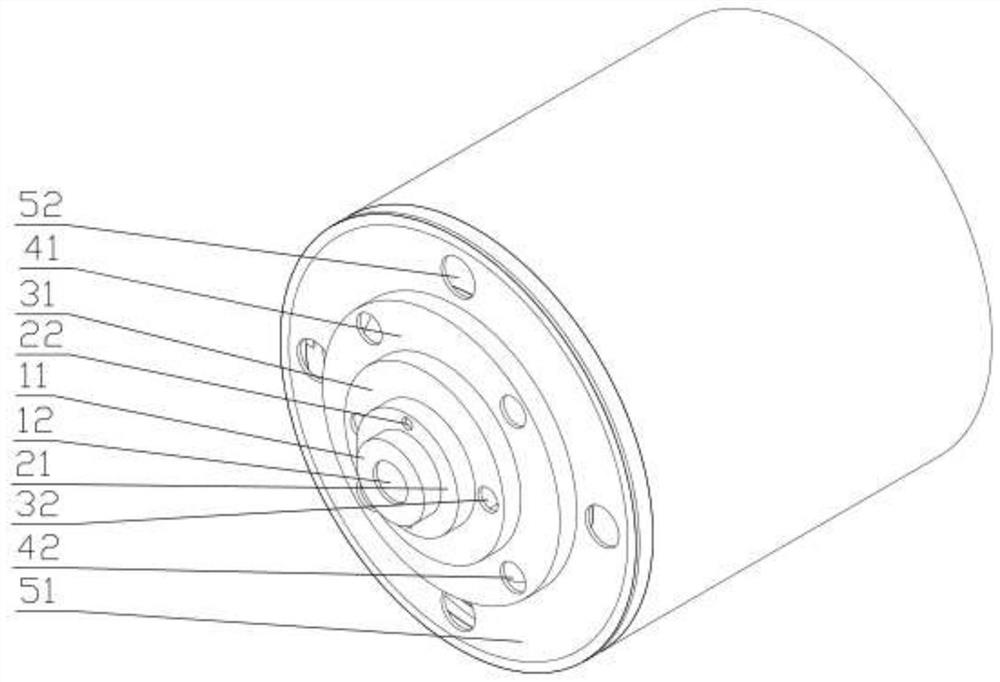

[0037] The air supply device for the spray gun of the rotary kiln in this embodiment includes a multi-layer ring-shaped air supply layer, which is the central ventilation layer 1, the gas flow layer 1, the outer ring ventilation layer 3, and the gas flow layer 2 4 from the inside to the outside. 1. Outer ring ventilation layer two 5; the inner surfaces of the central ventilation layer 1, the outer ring ventilation layer one 3, and the outer ring ventilation layer two 5 are all provided with air guide strips 6 extending helically along the annular surface; the gas flow layer Both the first 2 and the gas flow layer 2 4 are set as a plurality of gas flow vents 7 for gas supply along the circumference; the tail end of the gas supply layer is provided with a tail end connecting plate, and the tail end connecting plate is sequentially arranged with a center Ventilation layer sealing circular plate 11, gas flow layer one sealing ring plate 21, outer ring ventilation layer one sealing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com