Fabricated vertical shaft barrel structure and design and construction method

A construction method and assembled technology, which is applied in shaft equipment, shaft lining, mining equipment, etc., can solve the problems of complex scaffolding system construction, large construction safety hazards, and many construction procedures, so as to achieve easy product quality assurance and high production efficiency , a high degree of standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

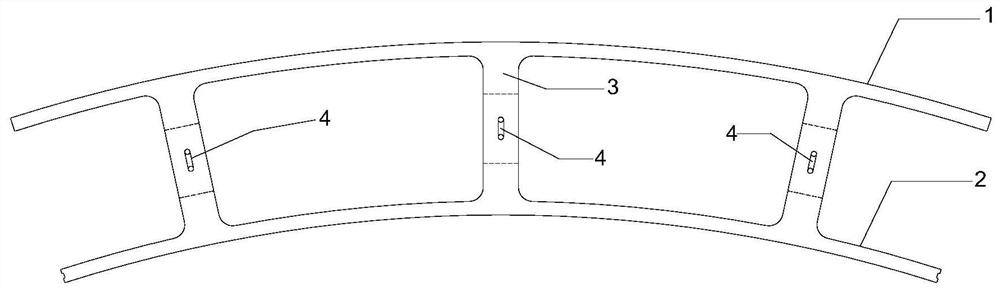

[0044] The shaft shell is assembled by multiple double-walled standard components, such as figure 1 with figure 2 As shown, it is a top plan view and a cross-sectional view of the double-wall panel standard component of the present invention. A single double-wall panel standard component is a "dumb bell" formed by an outer formwork wall 1, an inner formwork wall 2, and three inner and outer wall connecting beams 3. structure, the upper part of the single internal and external wall connecting beam 3 is pre-embedded with a lifting point 4, and a square hole 5 is reserved in the middle position. The vertically distributed steel bars 7, the horizontal circumferentially distributed steel bars 6 and the vertically distributed steel bars 7 are cross-welded together and distributed in a network structure.

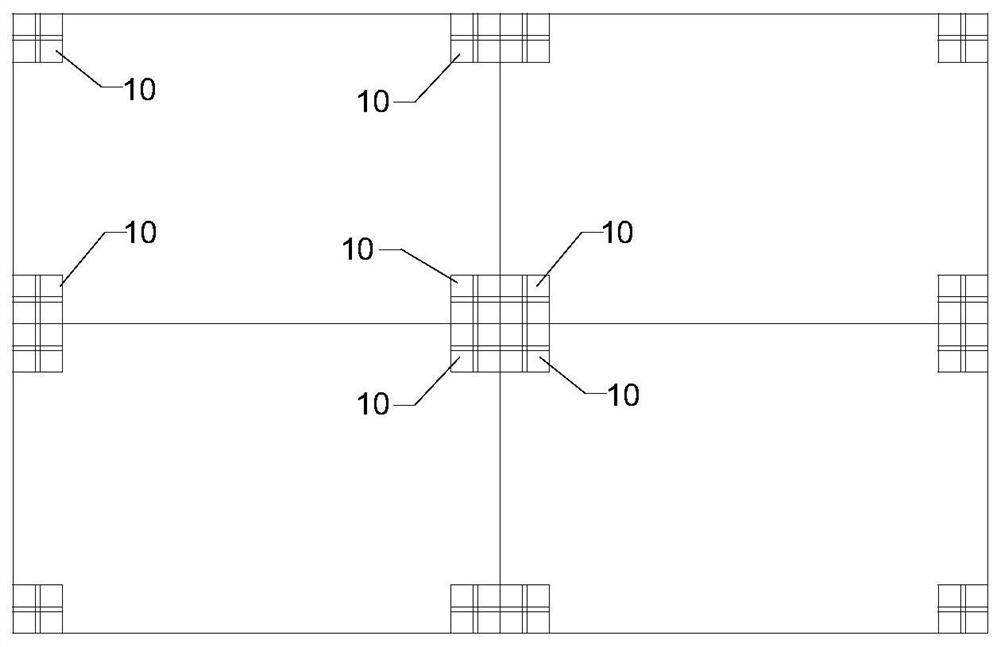

[0045] Each double-wall panel standard component is welded with the double-wall panel standard component in the adjacent direction through the corner pre-embedded connector 10 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com