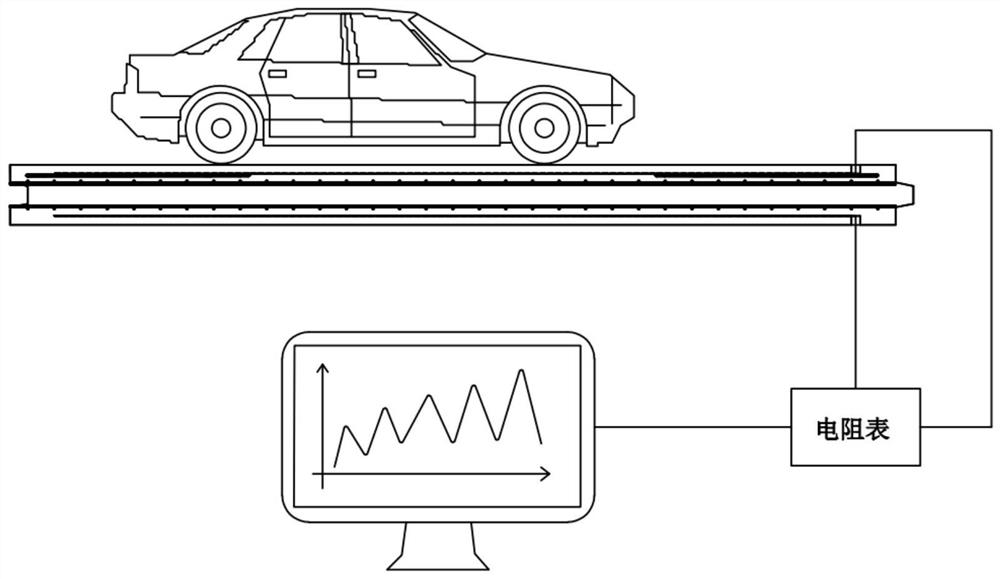

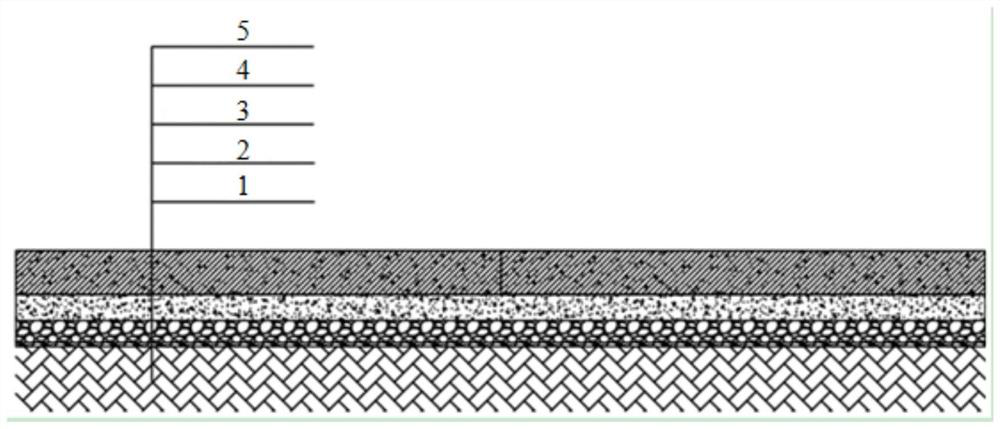

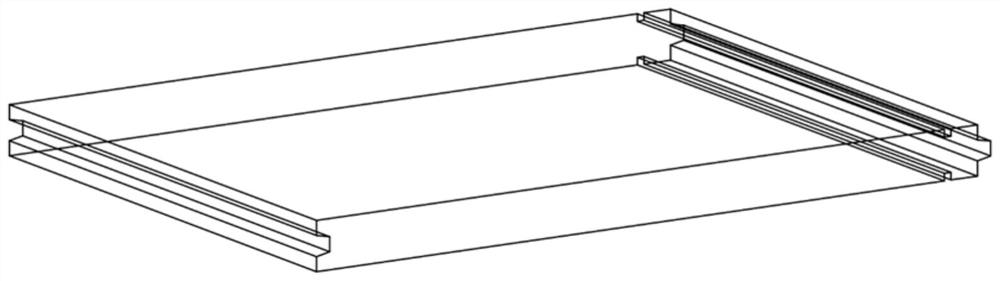

Piezoresistance self-sensing cement concrete material, pavement structure and paving method

A technology of cement concrete and pavement structure, applied in the field of building materials, can solve the problems of affecting the self-perception concrete sensing function, reducing the performance of concrete microstructure, and high cost of self-perceiving concrete, so as to improve the self-perception function, improve the conductivity, and facilitate the The effect of repair and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A piezoresistive self-sensing cement concrete material is composed of the following raw materials: cement, water, sand, gravel, graphite powder, steel slag, graphene nanoflakes, multi-walled carbon nanotubes and polycarboxylate superplasticizer , and the mass ratio of the above-mentioned raw material components is:

[0040] 1:0.34:1.161:2.592:0.129:0.288:0.05%:0.05%:0.2%.

[0041] Among them, the cement is P.O42.5 ordinary Portland cement, the particle size of steel slag is 5-10 mm, continuous gradation, the surface is rough and porous, the particle size of graphite powder is 325 mesh, the diameter of graphene nano flakes is 5-10 μm, and the thickness is 4-20nm, the carbon nanotubes are multi-walled carbon nanotubes with a diameter of 10-20nm and a length of not more than 50μm. Multi-walled carbon nanotubes can be surface-functionalized with Fenton's reagent oxidation and ultraviolet radiation (UV radiation) to enhance the compression sensitivity of this self-sensing c...

Embodiment 2

[0051] The prefabricated cement concrete pavement structure with self-sensing piezoresistance function and its laying method provided in this embodiment are the same as those provided in Example 1, the difference is only that the composition ratio of cement concrete materials with self-sensing piezoresistance is different, specifically cement, water , sand, gravel, graphite powder, steel slag, graphene nanoflakes, multi-walled carbon nanotubes and polycarboxylate superplasticizer, the mass ratio is 1:0.34:1.1481:2.4768:0.1419:0.4032:0.1%:0.05 %: 0.4%.

Embodiment 3

[0053] The prefabricated cement concrete pavement structure with self-sensing piezoresistance function and its laying method provided in this embodiment are the same as those provided in Example 1, the difference is only that the composition ratio of cement concrete materials with self-sensing piezoresistance is different, specifically cement, water , sand, gravel, graphite powder, steel slag, graphene nanoflakes, multi-walled carbon nanotubes and polycarboxylate superplasticizer, the mass ratio is 1:0.34:1.1352:2.3616:0.1548:0.5184:0.05%:0.1 %: 0.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com