Novel building dump truck hopper capable of reducing dust

A technology for dump trucks and truck bodies, which is applied in the arrangement of loading and unloading vehicles, vehicles used for freight, vehicles with inclined bearing motion, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

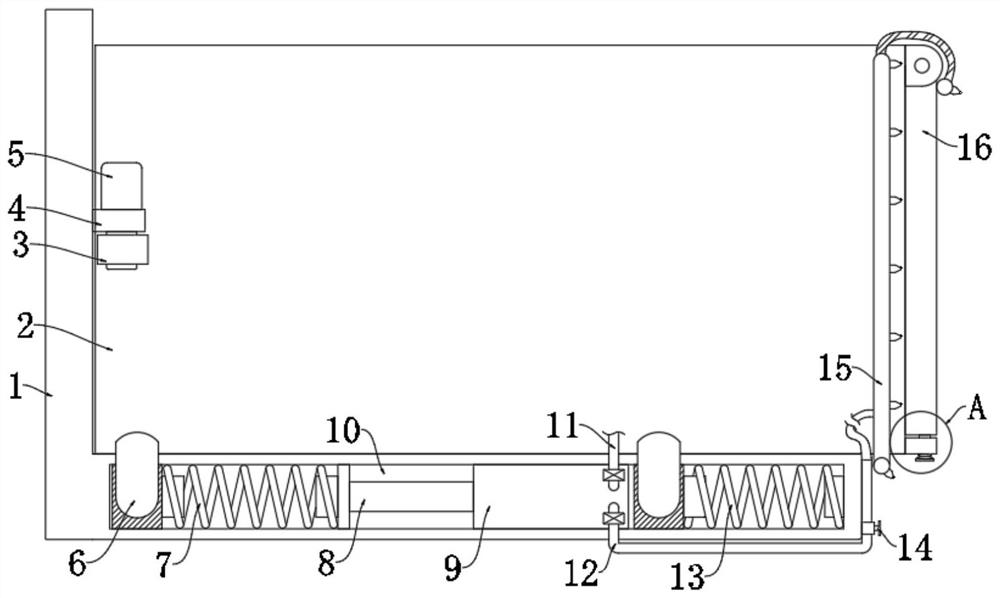

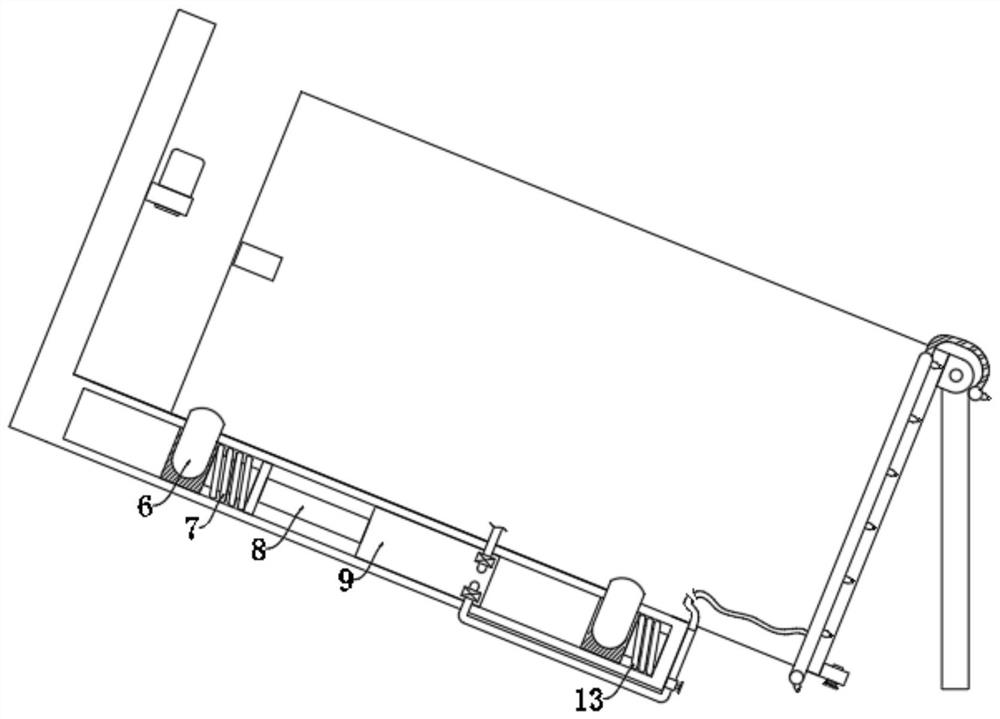

[0025] refer to Figure 1-3 , a new type of dust-reducing construction dump truck body, including an L-shaped frame 1 and a body 2 arranged on the frame 1, the frame 1 is provided with a fixing mechanism for fixing the body 2, the frame 1 A chute 10 is provided on the side of the horizontal part of the car body 2, and two connecting sliders 6 are fixedly connected to both sides of the vehicle body 2. The water storage piston cylinder 9 between the blocks 6, the water storage piston cylinder 9 is connected with a water inlet pipe 11 and a water outlet pipe 12, the water storage piston cylinder 9 can temporarily store water for dust spraying, and the water outlet pipe 12 is provided with a valve 14 The water storage piston barrel 9 is provided with a piston rod 8 at one end near the front side, the first spring 7 is connected to the connecting slider 6 on the front side, the other end of the first spring 7 is connected to the piston rod 8, and the connecting slider 6 on the rear...

Embodiment 2

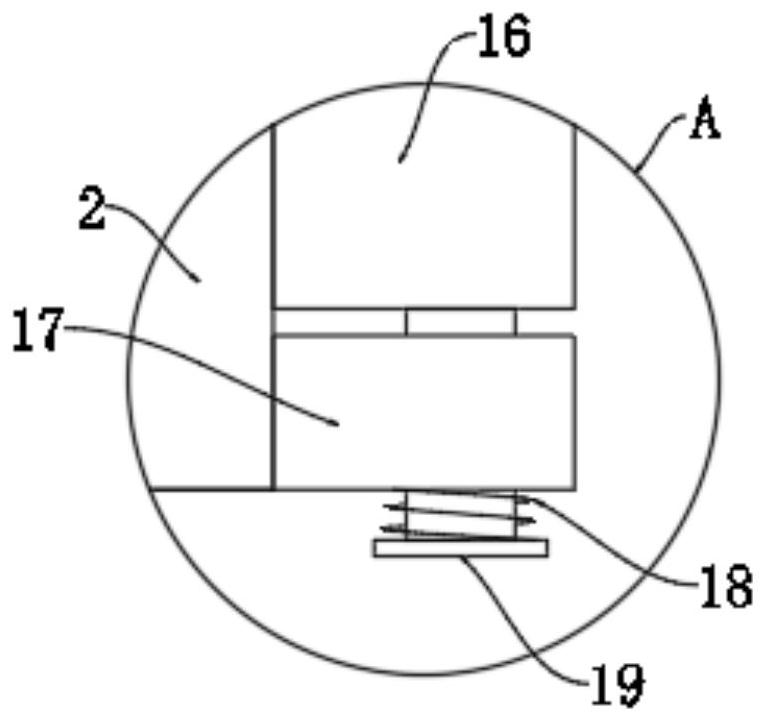

[0032] refer to Figure 4 , 5 Compared with Embodiment 1, the advantage of this embodiment is that the lower side of the fixed block 17 and the rear end of the vehicle frame 1 in this embodiment are equipped with a guide wheel frame 21, and the guide wheel frame 21 is provided with a guide wheel 22 , the two guide wheel frames 21 are threaded with the same rope 23, and the rope 23 fits the wheel surface of the guide wheel 22, the rope 23 passes through the guide wheel frame 21 and is limited by the guide wheel frame 21, and the guide wheel 22 pairs The rope 23 guides, the valve 14 is a pull rod valve, and the pull rod of the pull rod valve is sleeved with a second extension spring 20, and the two ends of the rope 23 are respectively connected to the insertion rod 19 and the pull rod of the pull rod valve.

[0033] When this embodiment is working, since the valve 14 is set as a pull rod valve, and the pull rod of the pull rod valve is covered with a second extension spring 20,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com