Wheel-side electric drive axle mechanical differential mechanism

A mechanical, differential technology, applied in control devices, transportation and packaging, vehicle components, etc., can solve the problems of unilateral weight of electric drive axles, unreasonable structural design, poor driving stability, etc., to achieve a wide range of applications. , The effect of ingenious structural design and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

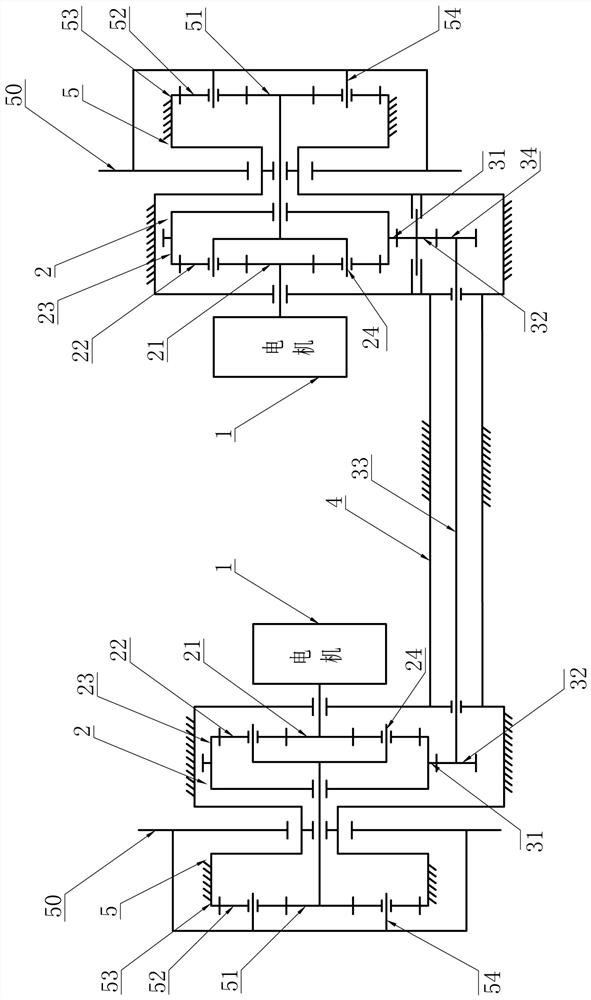

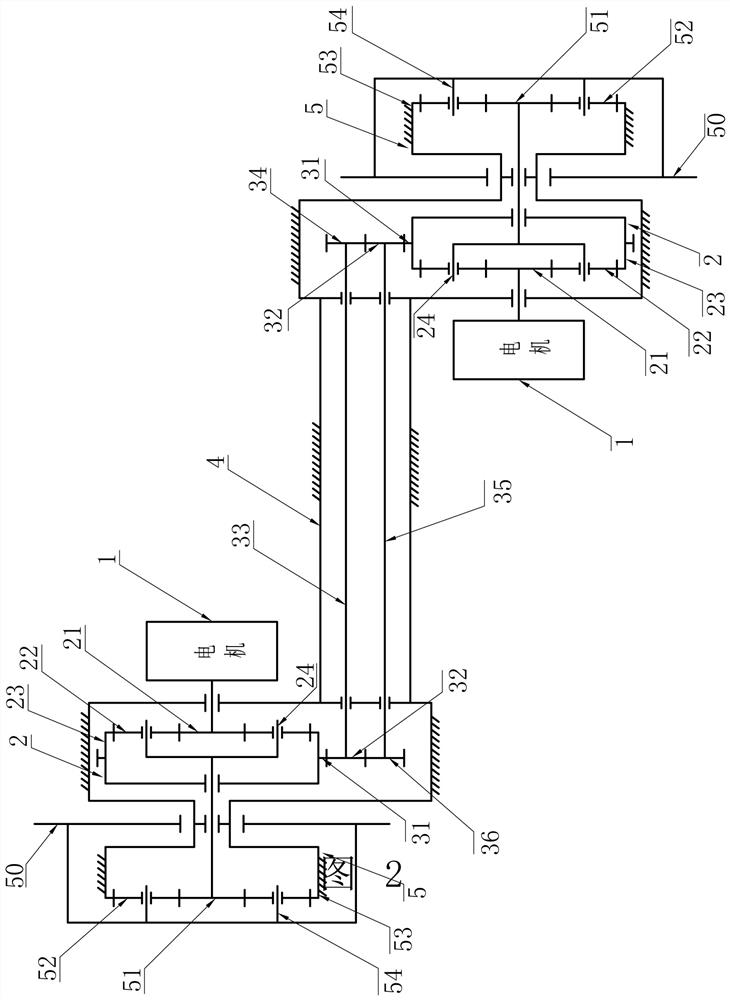

[0021] refer to figure 1 , a wheel-side electric drive axle mechanical differential, including electric drive axle 4 and motors 1 arranged on the left and right sides of electric drive axle 4, planetary transmission mechanism and differential mechanism. The motor 1 is drivingly connected to the planetary transmission mechanism, and outputs power to the wheels through the planetary transmission mechanism. The differential mechanism includes a main differential gear 31 and an auxiliary differential gear 32. The main differential gear 31 is drive-connected to the planetary transmission mechanism and meshes with the auxiliary differential gear 32; it also includes a first differential shaft 33 and an electric drive The right differential gear 34 on the right side of the bridge, the right differential gear 34 meshes with the auxiliary differential gear 32 located on the right side of the electric drive axle 4, and is connected to the left differential gear 32 located on the left si...

Embodiment 2

[0027] refer to figure 1 and figure 2 , different from Embodiment 1, Embodiment 2 also includes a second differential shaft 35 and a left differential gear 36 located on the left side of the electric drive axle 4, and the left differential gear 36 and the secondary differential gear located on the left side of the electric drive axle 4 The speed gears 32 mesh with each other, and are connected to the auxiliary differential gear 32 on the right side of the electric drive axle through the second differential shaft 35 . Designing two differential shafts to transmit torque can ensure the stability and reliability of the differential structure, even if one of them is broken during use, it can still operate normally.

Embodiment 3

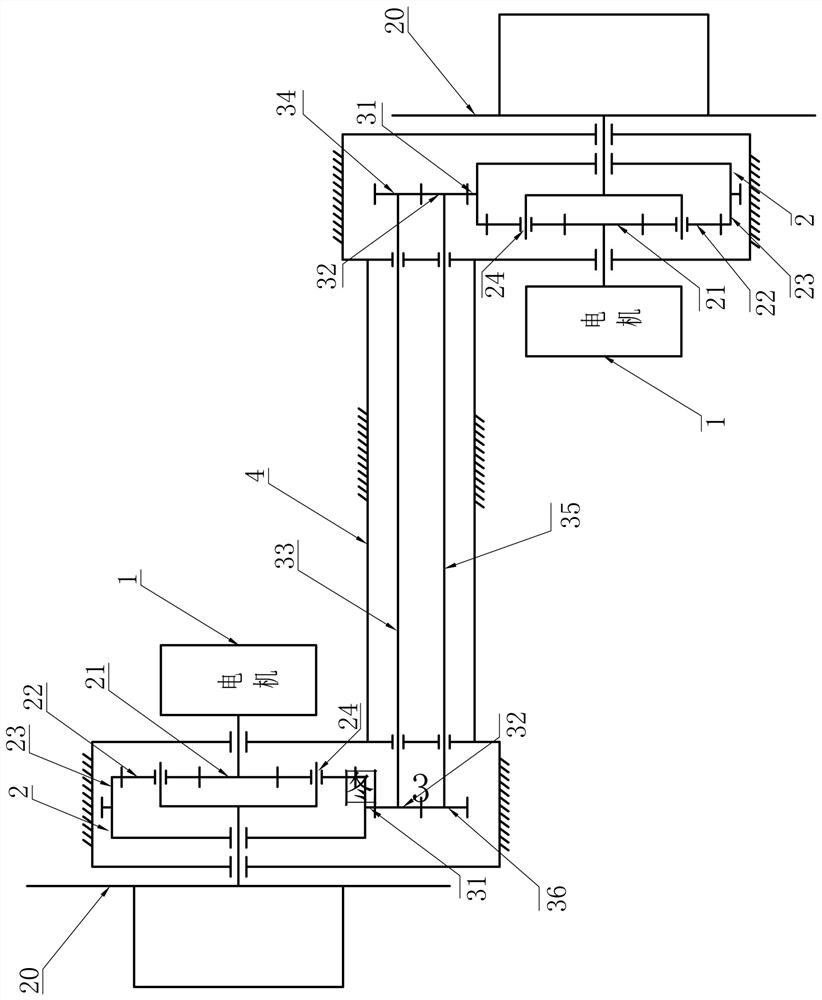

[0029] refer to figure 2 and image 3 , different from the second embodiment, the third embodiment does not set the second planetary row, but directly sets the mounting part 20 for mounting the wheel at the end of the output shaft, so that the differential can be adapted to a single tire vehicle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com