A flexible grasping device for industrial robots

An industrial robot and grasping device technology, applied in the directions of manipulators, manufacturing tools, chucks, etc., can solve the problems of incapable of grasping workpieces of different shapes, increase work intensity, reduce daily output, etc., so as to reduce maintenance costs and improve work. Efficiency, avoid the effect of reducing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

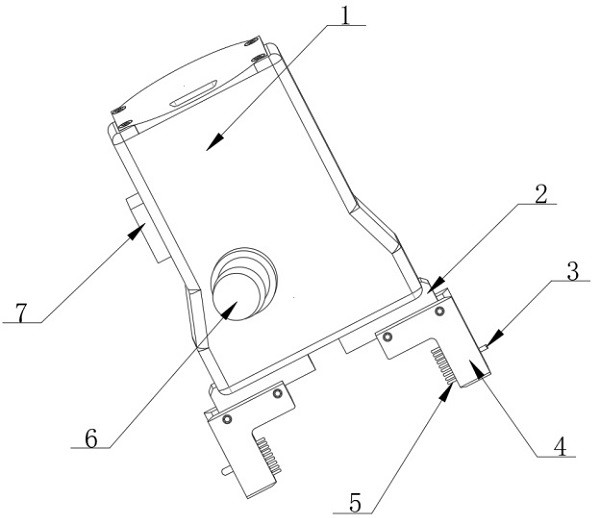

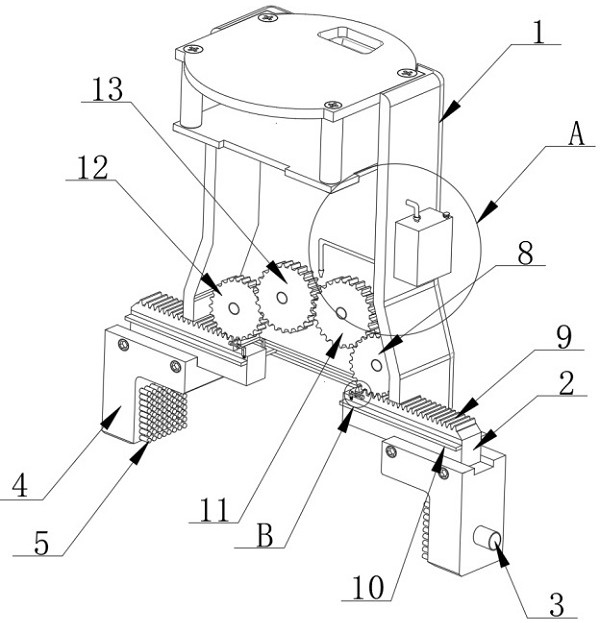

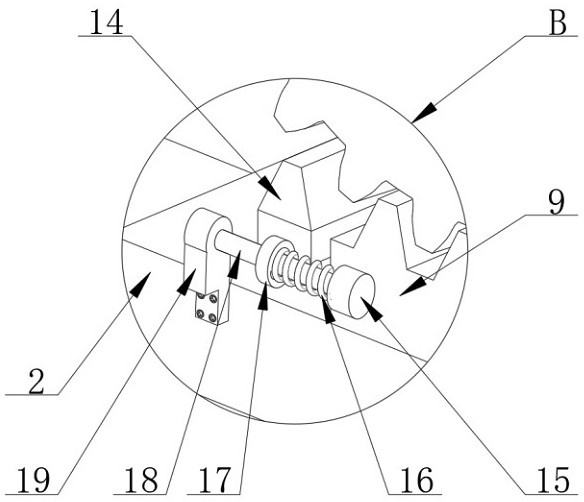

[0020] see Figure 1-5 , in an embodiment of the present invention, a flexible grabbing device for an industrial robot includes a housing 1, two sliding seats 2 are symmetrically slidably connected to the bottom of the housing 1, and guides are fixed on both sides of the sliding seat 2 The inner side of the plate 10 and the housing 1 is provided with a guide groove matching with the guide plate 10, which can play the role of limit guide and ensure the stability of displacement.

[0021] The front side of housing 1 is equipped with driving motor 6, and the inside of housing 1 is connected with the driving gear 13 that links to each other with driving motor 6 power transmission shafts, and the inside of housing 1 is positioned at one side of driving gear 13 and is connected with The drive gear 13 is meshed with the linkage gear 11, the inside of the housing 1 is located at the position below the other side of the drive gear 13 and is rotatably connected with the second transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com