Piston ring clamping device with tidying function

A piston ring clamp and piston ring technology, which is applied in the direction of chucks, grinding machine parts, grinding feed movement, etc., can solve the problem that the operation stability of non-standard automatic processing equipment is greatly affected and the jaws are difficult to grasp , poor stability and other problems, to achieve the effect of reducing maintenance and repair costs, small contact area of side clamping, and stable clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

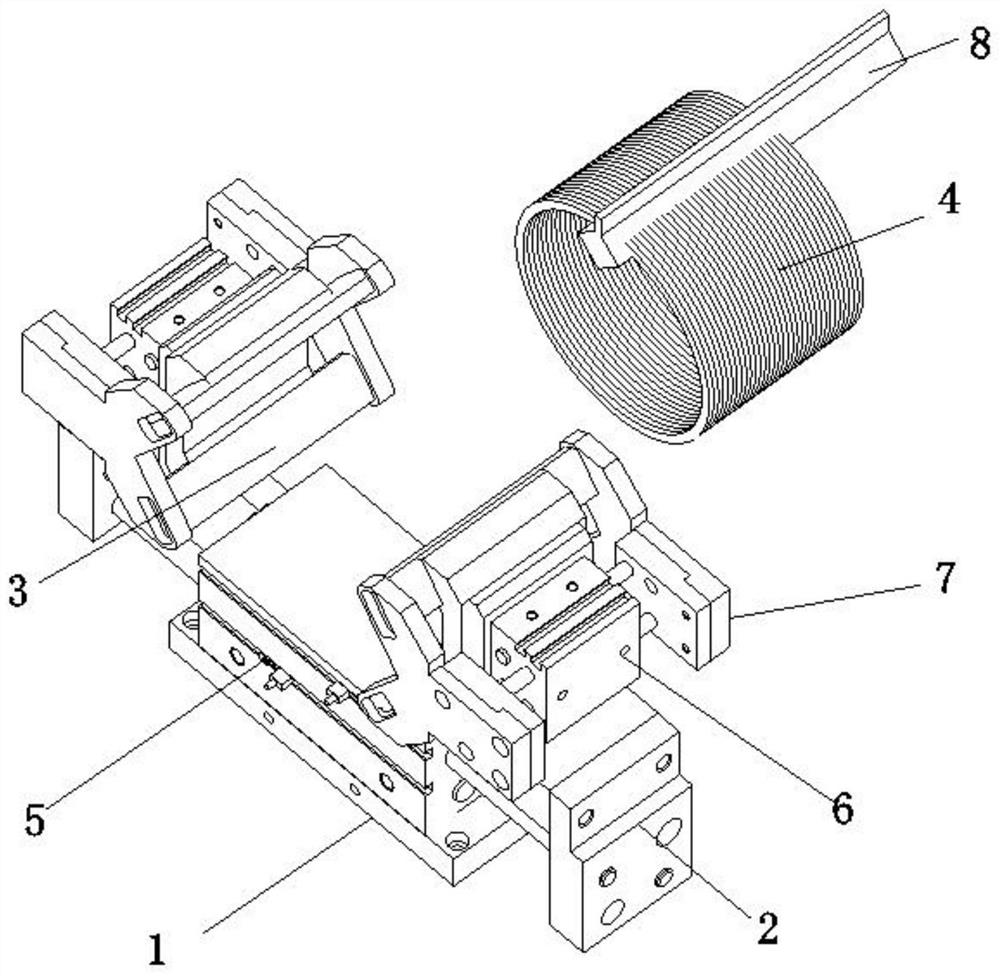

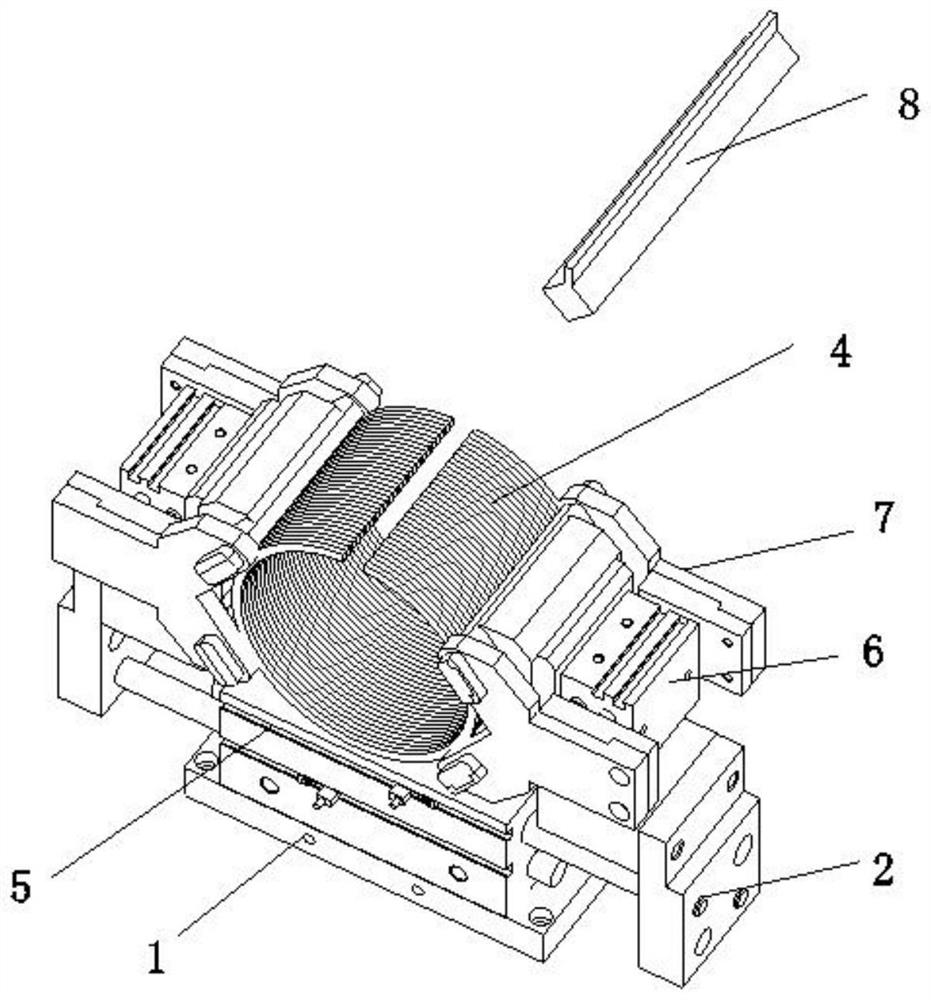

[0022] like Figure 1-2 As shown, a piston ring clamping device with finishing function, including a base 1,

[0023] The top of the base 1 is provided with a radial clamping mechanism, and the radial clamping mechanism is provided with an axial clamping mechanism;

[0024] The radial clamping mechanism includes two clamping seats 2, and a set of radial clamping plates 3 are arranged on the two clamping seats 2, which are symmetrically arranged, and the two radial clamping plates 3 are used for clamping batch piston rings 4;

[0025] A set of radial splints 3 is composed of two symmetrically arranged splints matched with the outer walls of the batch piston rings 4;

[0026] The batch of piston rings 4 is conveyed by an external conveying mechanism into the clamping regions of the radial clamping mechanism and the axial clamping mechanism.

[0027] The radial clamping mechanism includes an expanding and grasping cylinder 1 5, and the expanding and grasping cylinder 1 5 is a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com