Quick-cooling type laser processing device facilitating continuous production and processing method thereof

A laser processing and convenient technology, applied in the direction of laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of long cooling time of parts, achieve the effect of improving quality, preventing temperature overload, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

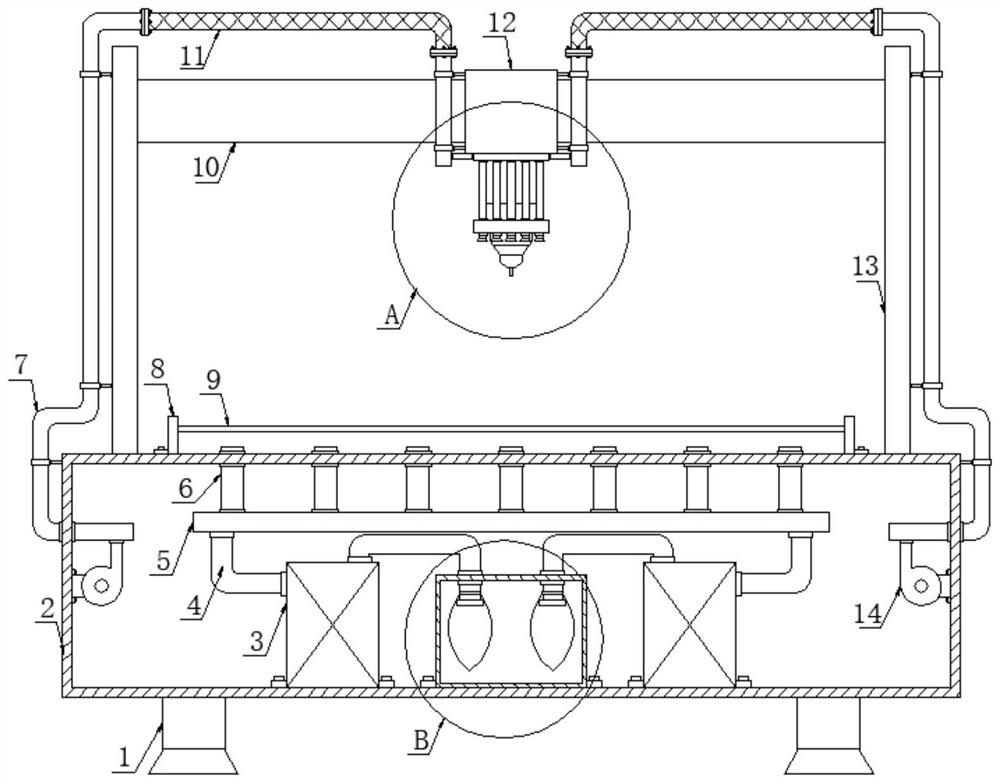

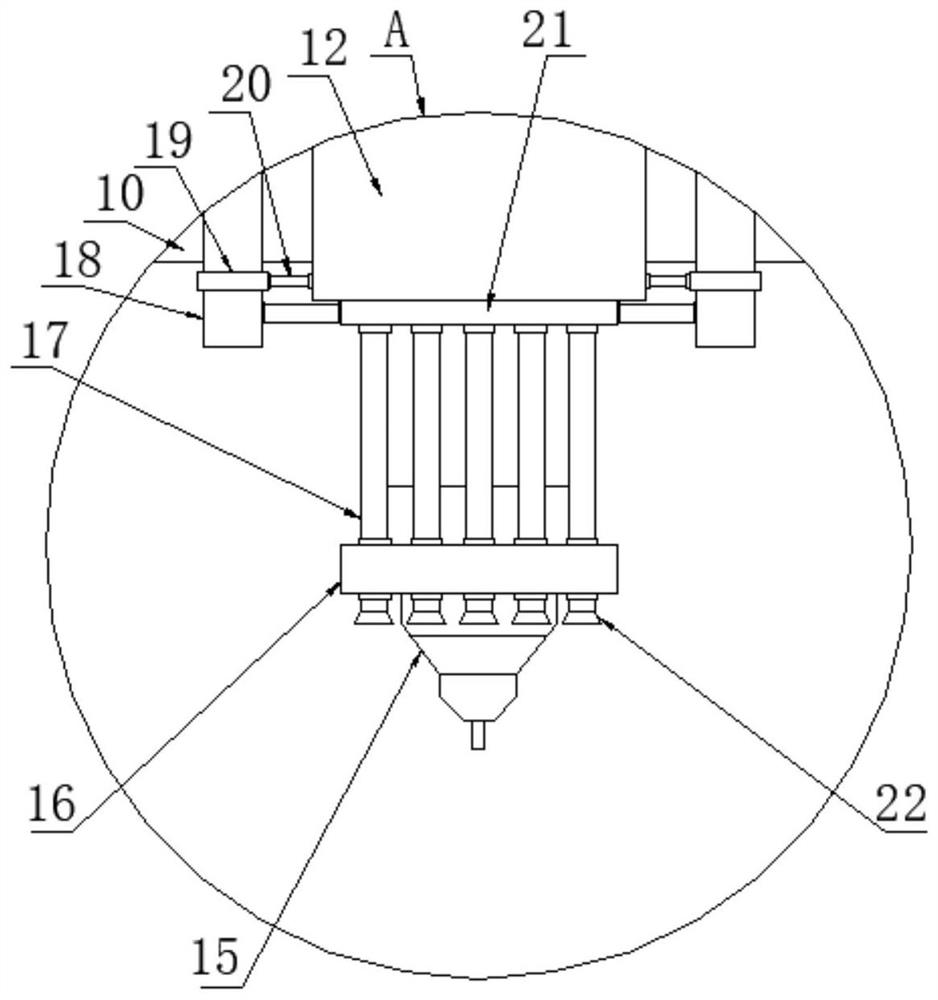

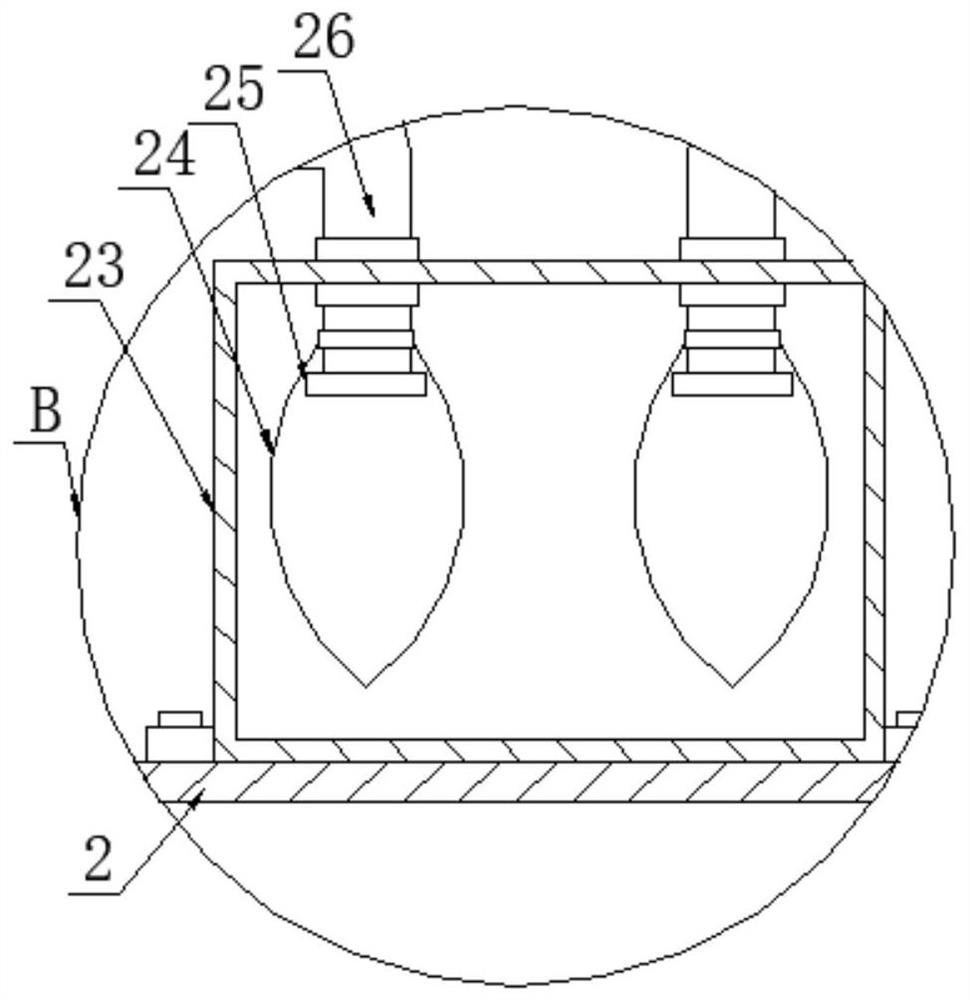

[0025] see Figure 1-4 , the present invention provides a technical solution: a fast-cooling laser processing equipment convenient for continuous production, please refer to figure 1 , including box body 2, two sets of side plates 13, mounting frame body 10, transmission frame 12 and laser cutting head 15, two sets of side plates 13 are symmetrically arranged on the top surface of box body 2, and two sets of side plates 13 and box The body 2 is fixedly connected, the mounting frame body 10 is arranged between two groups of side plates 13, the transmission frame 12 is arranged on the mounting frame body 10, the bottom end surface of the transmission frame 12 is provided with a laser cutting head 15, when cutting, the laser cutting The head 15 can facilitate the cutting work through the cooperation of the drive frame 12 and the mounting frame body 10 .

[0026] see figure 1 , the outside of the laser cutting head 15 is provided with a flexible blowing device, the temperature a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com