Concrete crushing and recycling device

A concrete and crushing box technology, which is applied in the direction of cleaning methods and appliances, using liquid separation agents, separation methods, etc., can solve the problems of not being able to completely and effectively realize environmental protection crushing, not being able to adjust concrete blocks in real time, and not being thorough enough, so as to maintain work Efficiency, prevent stuck, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

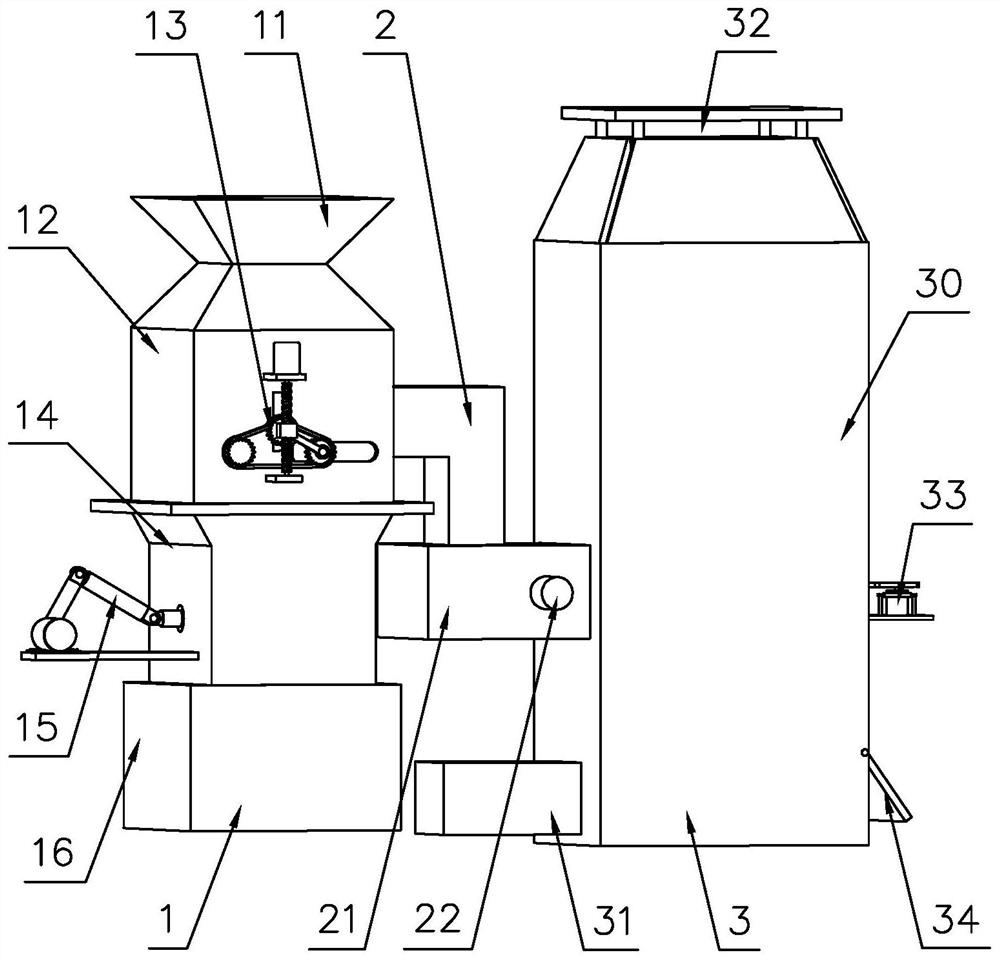

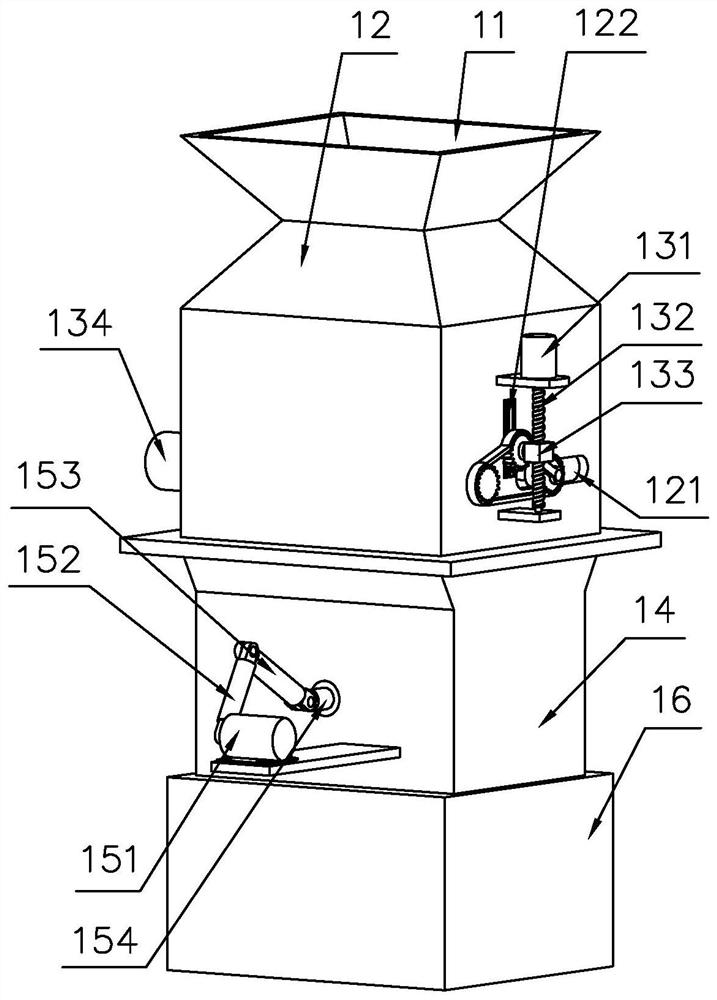

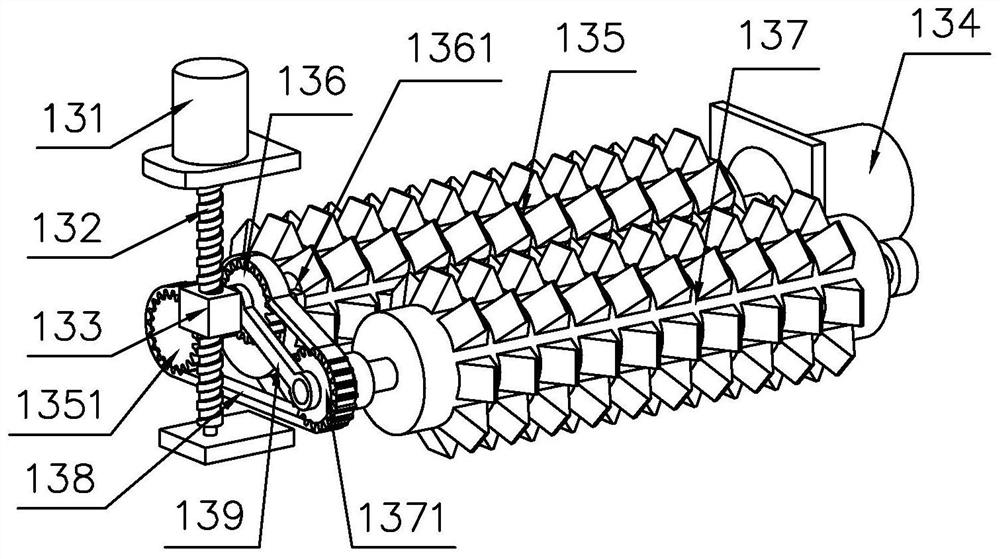

[0032] For the convenience of those skilled in the art to understand, the following in conjunction with the attached Figure 1-9 , to further specifically describe the technical solution of the present invention.

[0033] A device based on the recovery and reuse of broken concrete, including a crushing mechanism 1, a dust channel 2, and a mud generating mechanism 3. A dust channel 2 is provided on one side of the crushing mechanism 1, and a mud generating device is provided on one side of the dust channel 2. Mechanism 3. The crushing mechanism 1 includes a material inlet 11, a crushing box I12, a crushing roller adjustment mechanism 13, a crushing box II14, an extrusion mechanism 15, and an aggregate collection box 16. The side of the material inlet 11 is provided with a crushing Box I12, one side of the crushing box I12 is provided with a crushing roller adjustment mechanism 13, the other side of the crushing box I12 is provided with a crushing box II14, one side of the crush...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com