Preparation method of Bi12SiO20-Bi2O2SiO3/rGO photocatalyst

A photocatalyst, mass ratio technology, applied in the field of materials, can solve the problem of low photocatalytic efficiency, achieve high specific surface area, improve degradation efficiency, and improve the effect of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) get 0.5g graphite powder and concentration and be 98wt% vitriol oil with mass ratio m 石墨粉 :m 浓硫酸 = 1:70 mixing, stirring for about 30 minutes and adding 3g of KMnO with a mass ratio of about 5.5:1 4 and NaNO 3 The mixture was placed in an ice-water bath and stirred for 2 h, then placed in a 30°C water bath and stirred for about 2 h, and 130 mL of H 2 O, the temperature of the water bath was raised to 90°C, and the stirring was continued for about 2 hours to obtain a uniform mixed solution;

[0024] (2) Add 1 mL of 30% H to the above mixed solution 2 o 2 The solution was washed with deionized water, dried at 60°C, and dispersed ultrasonically (for about 30 minutes) to obtain graphene oxide, which was added to water to obtain a graphene oxide suspension;

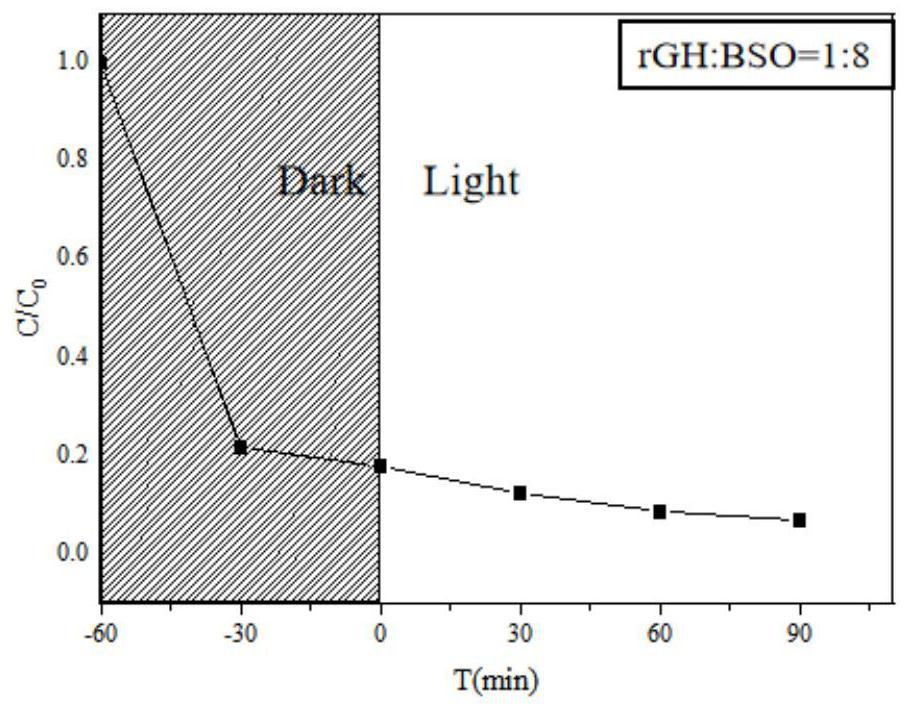

[0025] (3) Mix absolute ethanol and deionized water (volume ratio is about 1.8:1), add a certain amount of citric acid (after adding, the concentration of citric acid is 0.006mol / L), and add a certain amount of...

Embodiment 2

[0030] (1) Take 0.4g and mix it with 98wt% concentrated sulfuric acid (mass ratio 1:75), stir for about 40min and add 4g of a certain amount of KMnO 4 and NaNO 3 (mass ratio is about 7:1), put it in an ice-water bath and stir for 2.5 hours, then put it in a 30°C water bath and stir for about 2 hours, add 150mLH 2 O, the temperature of the water bath was raised to 100°C, and the stirring was continued for about 2 hours to obtain a uniform mixed solution;

[0031] (2) Add 3 mL of 30% H to the above mixed solution2 o 2 The solution was washed with deionized water, dried at 65°C, and then ultrasonically dispersed (about 30 minutes) to obtain graphene oxide;

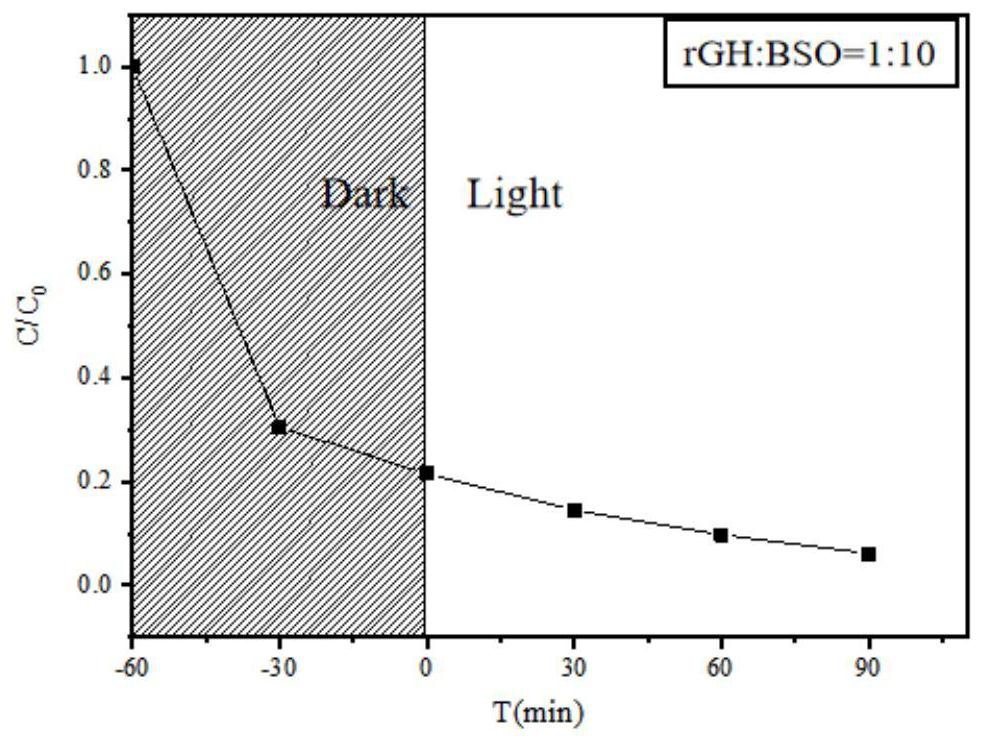

[0032] (3) Mix absolute ethanol with deionized water (volume ratio is about 2:1), add a certain amount of citric acid (concentration is 0.006mol / L) to it, and add a certain amount of bismuth nitrate ( Concentration is 0.005mol / L), stirred for about 1h until completely dissolved. At the same time, according to the ratio of...

Embodiment 3

[0037] (1) Take 0.4g and mix it with 98wt% concentrated sulfuric acid (mass ratio is 1:90), stir for about 50min and add 3.5g KMnO 4 and NaNO 3 (mass ratio is about 7:1), put it in an ice-water bath and stir for 2.5h, then put it in a 40°C water bath and stir for about 2h, add 130mLH 2 O, the temperature of the water bath was raised to 90°C, and the stirring was continued for about 2.5 hours to obtain a uniform mixed solution;

[0038] (2) Add 3mL of H 2 o 2 solution (30%), washed with deionized water, dried at 65°C, and dispersed by ultrasonic (about 30min) to obtain graphene oxide;

[0039] (3) Mix absolute ethanol with deionized water (volume ratio is about 2:1), add a certain amount of citric acid (concentration is 0.005mol / L) to it, and add a certain amount of bismuth nitrate ( Concentration is 0.006mol / L), stirred for about 1h until completely dissolved. At the same time, weigh a certain amount of tetraethyl orthosilicate and dissolve it in a certain amount of water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com