Organic waste liquid recovery equipment and method thereof

A technology of organic waste liquid and recycling equipment, applied in organic chemistry, separation methods, chemical instruments and methods, etc., can solve problems affecting the quality of recycled products, decomposition of target components, and other reactions, so as to reduce decomposition or other reactions Probability of reaction, reduced residence time, reduced effect of connecting pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

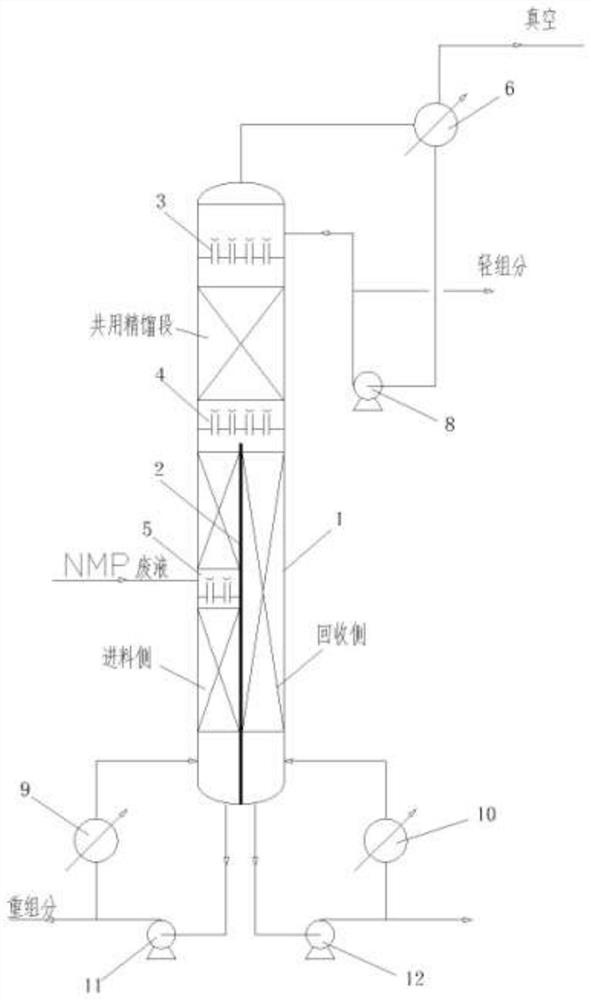

[0023] Such as Figure 2-3 As shown, this embodiment includes a dividing wall rectification column 1, which is divided into a feed side and a recovery side by a partition 2 in the dividing wall rectification column 1, and a third distributing device is provided on the feed side in the dividing wall rectification column 1. 5, a second distributor 4 is provided above the partition plate 2, a first distributor 3 is provided above the second distributor 4, and the common rectification section of the dividing wall rectification column 1 is located in the first distributor 3 and the second distributor 4. The main function of the common rectification section is to separate the target components from the light components, so that the content of light components in the liquid entering the feed side and recovery side is low.

[0024] The top of the next-wall rectification column 1 is connected to the input end of the first condenser 6 by a pipeline, and the output end of the first cond...

Embodiment 2

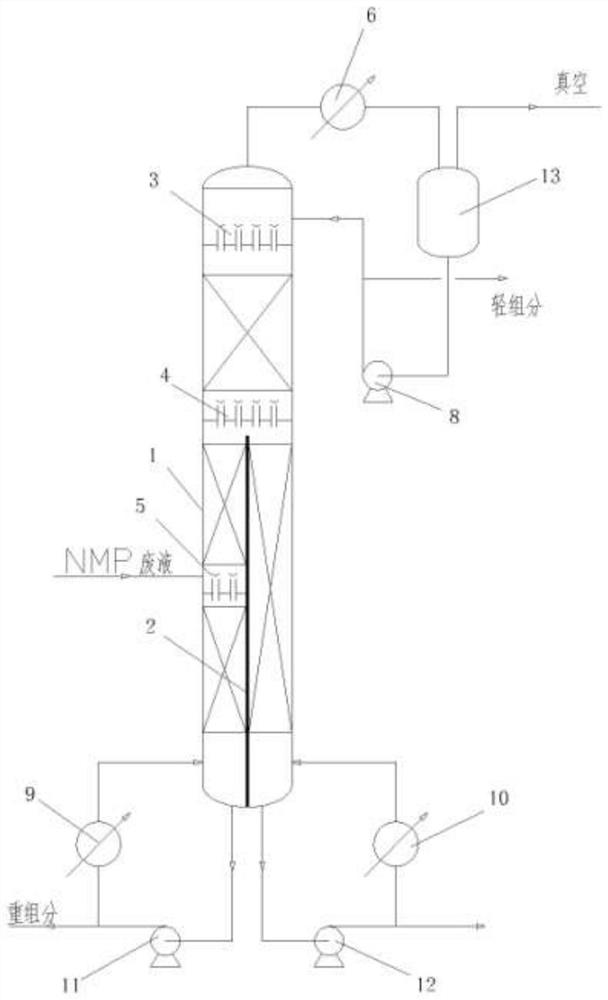

[0036] Such as Figure 4 As shown, the difference between this embodiment and embodiment 1 is that: the top of the rectifying column with dividing wall 1 is connected with two first condensers 6 and second condensers 7 connected in series through pipelines, and the output end of the first condenser 6 is passed through The pipes are respectively connected to the second condenser 7 and the upper part of the dividing wall rectification column 1 , and the second condenser 7 is connected to the top pump 8 . In this embodiment, all the condensate is returned to the next-door rectification column 1, and the vapor phase enters the second condenser 7 to condense and then enters the light component buffer tank 14, and then is output through the tower top pump 8.

[0037] In this embodiment, a vacuum buffer tank 15 connected to the light component buffer tank 14 may also be provided.

[0038] All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com