Decolorizing method of stevia sugar water extracting solution

A stir-frying and tea-leaving technology, which is applied in tea treatment before extraction, solid separation, and separation of solids from solids with airflow, etc. It can solve the problems of picking out, poor stir-frying effect, and lower tea quality, so as to improve the quality , good stir-frying effect, high-quality stir-frying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

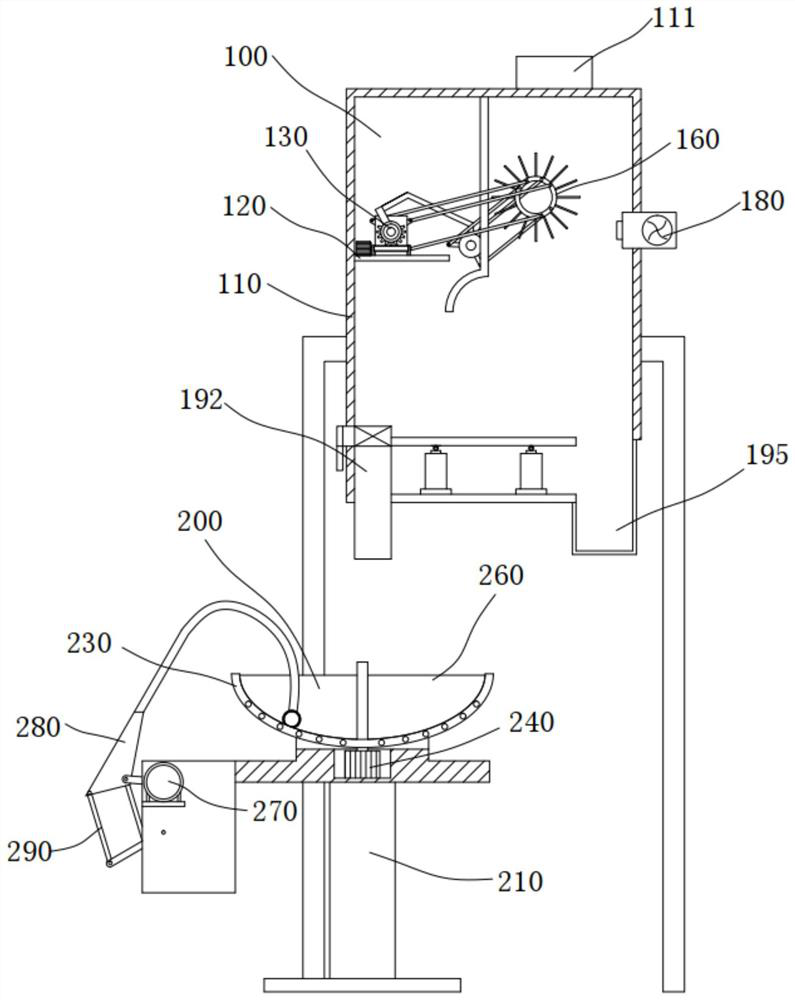

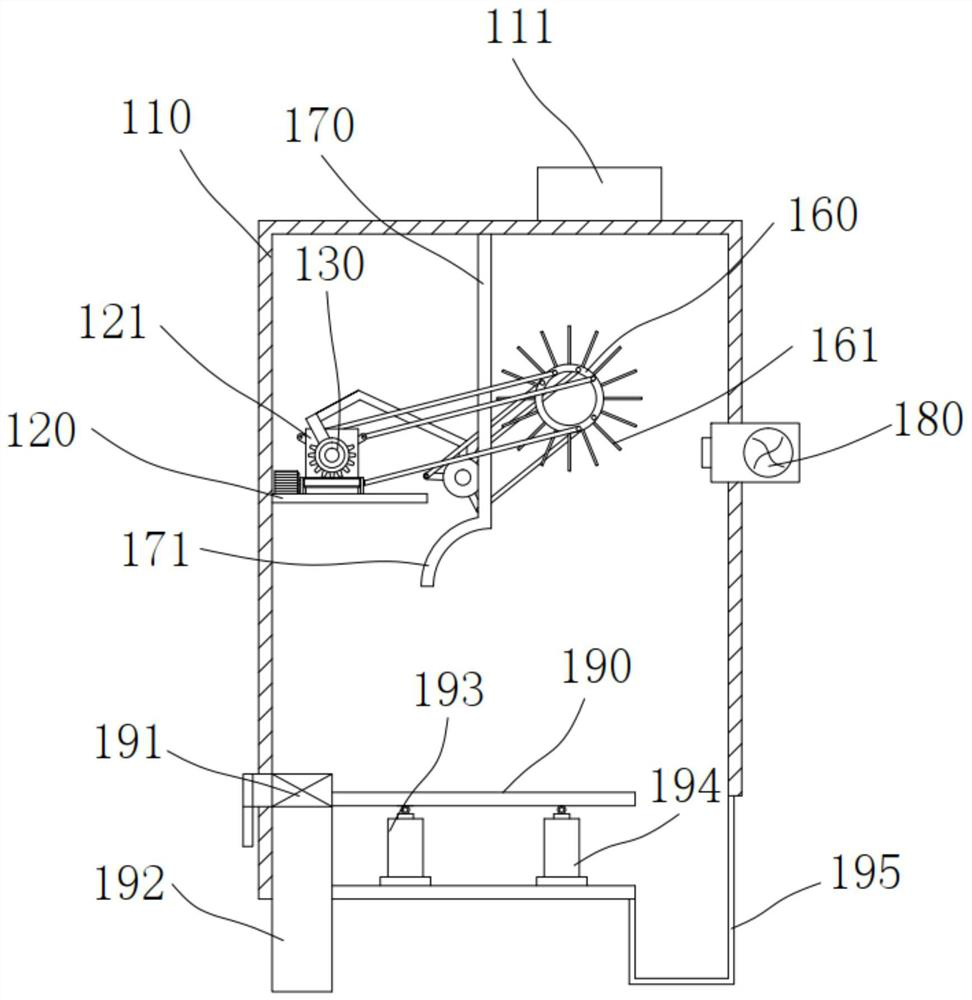

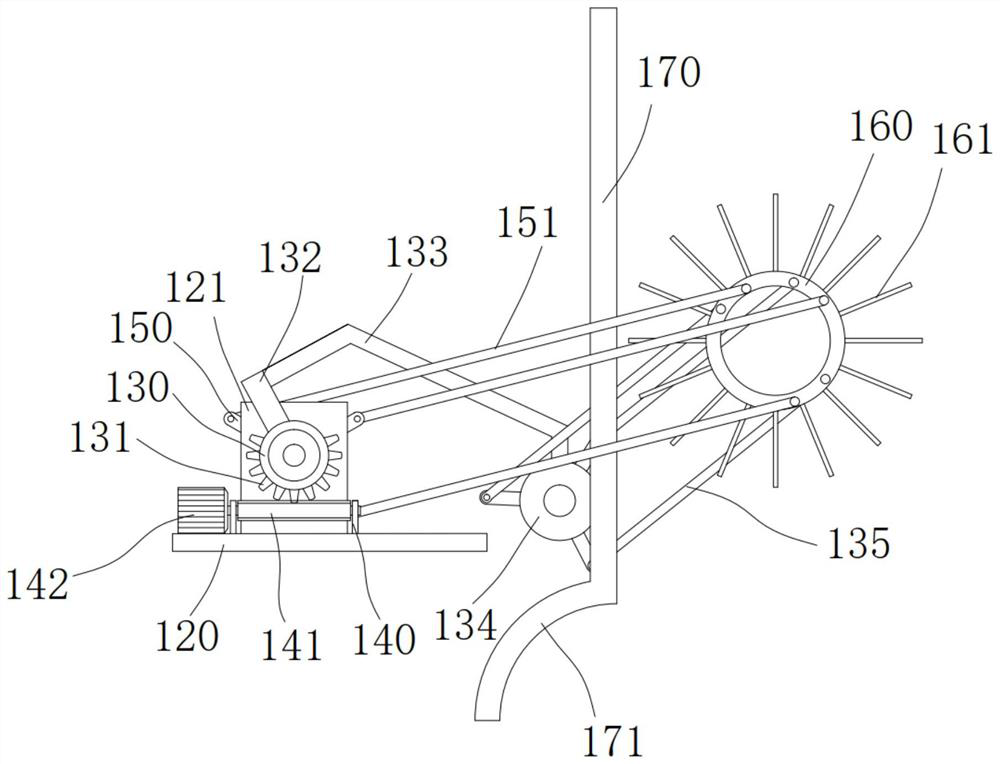

[0031] A kind of tea stir-frying device with screening function, comprises screening mechanism 100, and screening mechanism 100 comprises screening box 110, and the upper end of screening box 110 is provided with feeding port 111, and installing plate 120 is arranged in screening box 110, and the upper end of mounting plate 120 One side is provided with a riser 121, one side of the riser 121 is rotatably connected with an adjustment wheel 130, the outer wall of the adjustment wheel 130 is provided with a worm wheel ring 131, the mounting plate 120 is provided with a bracket 140, and the bracket 140 is rotatably connected with a worm 141, the worm 141 Engaged with the turbine ring, the mounting plate 120 is provided with a first motor 142 at one end of the bracket 140, the output shaft of the first motor 142 is driven and connected with the worm 141, and the outer wall of the screening box 110 is provided with a second motor, and the output shaft of the second motor extends to T...

Embodiment 2

[0036] Stir-fry mechanism 200, stir-fry mechanism 200 is arranged below screening mechanism 100, stir-fry mechanism 200 comprises fixed platform 210, and fixed platform 210 upper end is provided with support seat 220, and support seat 220 upper end is provided with pot body 230, and pot body 230 wall has A interlayer, a heating wire is arranged in the interlayer, a side plate 221 is arranged on one side of the fixed platform 210, a third motor 270 is fixedly installed on the side plate 221, the output shaft of the third motor 270 is connected with a rotating arm 271, and the rotating arm 271 is hinged with a turning arm Stir-fry arm 280, the lower end of stir-fry arm 280 is movably connected with side plate 221 through movable assembly 290, and the upper end of stir-fry arm 280 is connected with stir-fry claw 281, and stir-fry claw 281 is an arc structure, and stir-fry claw 281 extends to the pot body In 230, the stir-fry claw 281 is connected with a stir-fry brush 282, and the...

Embodiment 3

[0040] The pot body 230 is provided with a stirring mechanism, and the stirring mechanism includes a rotating rod 250, a partition blade 260 and a fourth motor 240. The middle part of the pot body 230 is provided with a rotating rod 250. The lower side of the partition blade 260 has an arc edge respectively, and the arc edge is matched with the inner wall of the pot body 230. Four groups of partition blades 260 divide the pot body 230 into four groups of stir-frying chambers 261. There is a cavity in the support seat 220. A fourth motor 240 is installed in the body, and the output shaft of the fourth motor 240 is drivingly connected to the rotating rod 250;

[0041] The third motor 270 drives the stir-frying frequency of the stir-fry arm 280 to match the rotation frequency of the fourth motor 240 to drive the rotating rod 250, and the stir-fry arm 280 drives the stir-fry claw 281 to swing back and forth in the pot body 230, and the stir-fry claw 281 Drive the stir-fry brush 28...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com