Robot magneto-rheological polishing tool head calibration device and method based on tracker

A magnetorheological polishing and tool head technology, which is applied in the direction of machine tools and instruments that use optical devices and are suitable for grinding the edge of workpieces, can solve the problem that the magnetorheological polishing tool head has a special shape and is difficult to meet the requirements of the magnetorheological polishing tool head. Calibration needs and other issues, to achieve the effect of rapid coordinate system calibration, convenient and fast installation, and simple relative relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to better present the technical solutions and advantages of the present invention, in combination with Figure 1-Figure 10 The specific implementation plan is described. This section presents a typical implementation of the present invention, and the implementation can be optimized according to the characteristics and requirements of the magnetorheological polishing tool, all of which belong to the protection scope of the present invention.

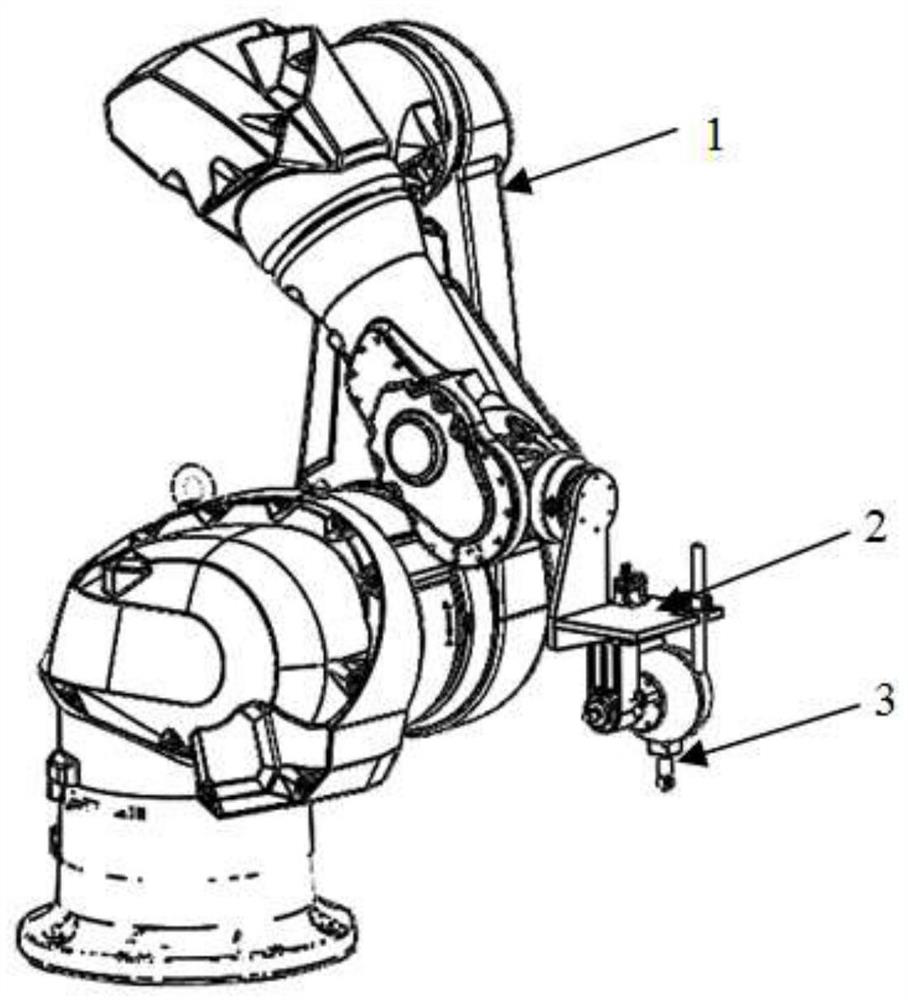

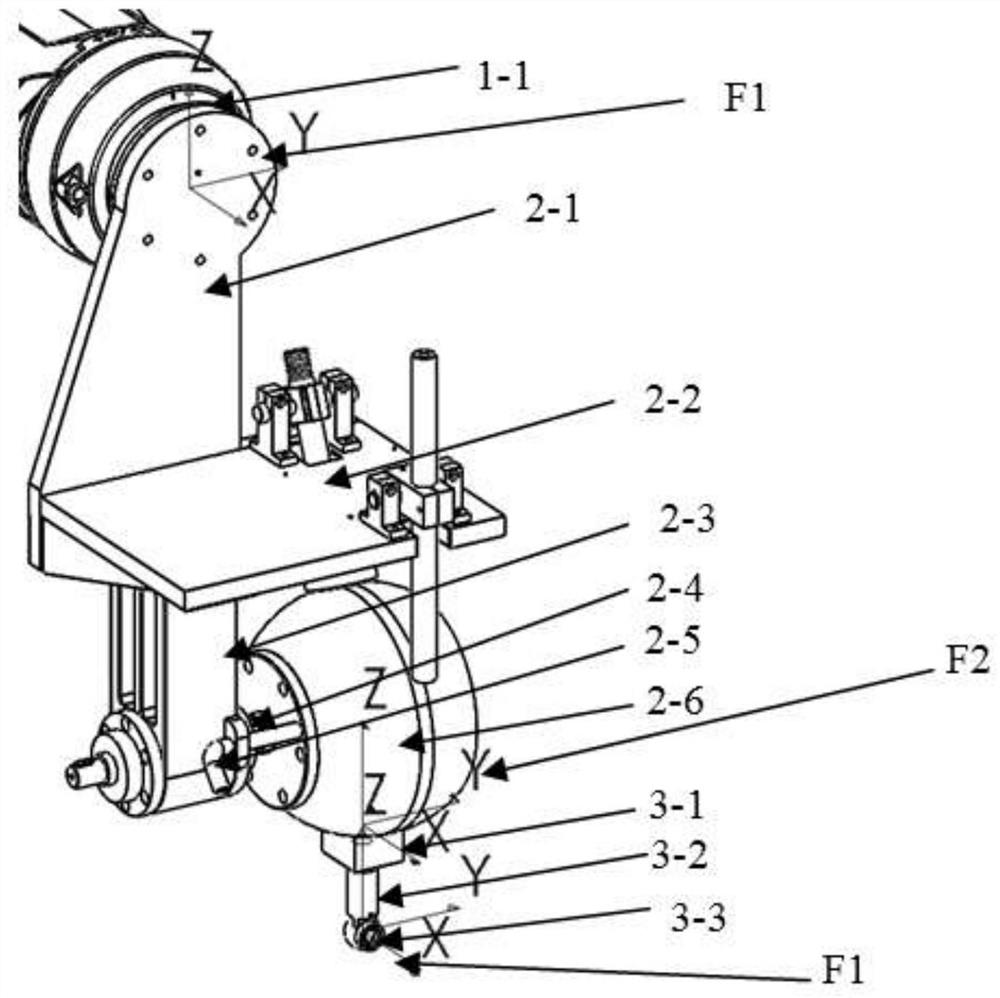

[0033] The magnetorheological polishing tool head calibration device for a robot based on a tracker of the present invention includes a robot 1 , a magnetorheological polishing tool head 2 and a calibration device 3 . The magnetorheological polishing tool head 2 and the calibration device 3 include a tool head adapter plate 2-1, a tool head fixing plate 2-2, a bearing seat 2-3, a positioning pin shaft seat 2-4, and a positioning pin shaft 2- 5. Magnetorheological polishing wheel 2-6, calibration tool holder 3-1, cylindric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com