Suction-spraying type dense filling device and method for hole and pore

A technology of holes and pores, which is applied in the field of suction-spray dense irrigation and filling devices, can solve the problems of dense filling, hidden dangers of construction engineering quality and safety, and influence on the overall aesthetic performance of buildings, so as to eliminate potential safety hazards and improve the overall aesthetic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

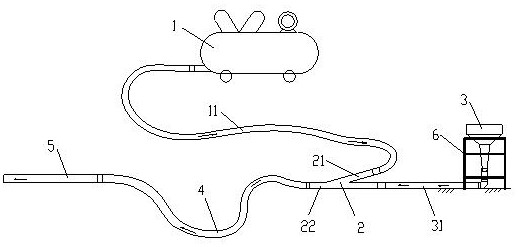

[0016] Example figure 1 As shown, the suction-spray type dense filling device for holes and pores of the present invention includes an air compressor, an inclined three-way pipe joint 2, a funnel 3, a steel wire hose 4 and a grouting material delivery pipe 5, and the output end of the air compressor 1 is Connect the input port of the inclined pipe 21 of the inclined three-way pipe joint 2 through the flexible pipe 11, and the output end of the funnel 3 is connected to the input port of the straight pipe 22 of the inclined three-way pipe joint 2 through the pipeline 31. The input port of the straight pipe 22 of the pipe section 2 is connected to the input port of the grouting material delivery pipe 5 through the steel wire hose 4 .

[0017] Preferably, the device further includes a bracket 6 on which the funnel 3 is seated. The funnel is supported by brackets to ensure the stability of the funnel setup.

[0018] Preferably, the included angle between the inclined pipe 21 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com