A kind of fluorescent superhydrophobic fiber cloth and preparation method thereof

A super-hydrophobic and fiber cloth technology, which is applied in textiles and papermaking, can solve the problems of complex preparation methods, low repeatability, and low oil-water separation effect, and achieve simple preparation methods, uniform hydrophobic properties, and complete mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

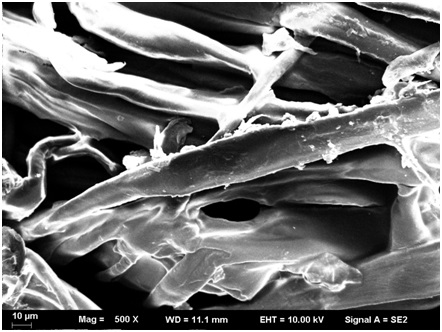

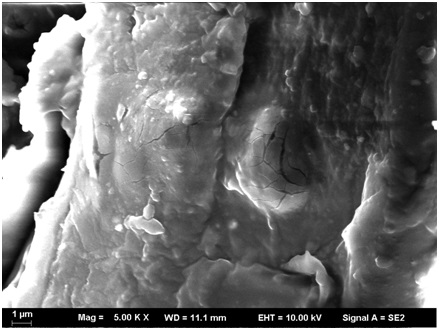

Image

Examples

Embodiment 1

[0035] In the first step, MMA, HPA, 2-EHA, and GMA are used as monomers, AIBN is used as an initiator, and butyl acetate is used as a solvent to synthesize an acrylic resin. The percentages in this step are the percentages of the total mass of the raw materials used to synthesize the acrylic resin. First add 27% butyl acetate into a three-necked flask and heat to 82°C, then accurately weigh 1.8% AIBN, 0.5% chain transfer agent, 23.68% MMA, 3.125% HPA, 23.195% 2-EHA, 12.5% GMA and 3.5% Butyl acetate, mixed and dissolved, was added dropwise into a three-necked flask, and the dropping time was controlled to be 4 hours. After the dropwise addition was complete, the temperature was raised to 85°C, kept for 5 hours, and then 0.2%g AIBN and 4.5%g butyl acetate were added Ester, continue to keep warm for 1 hour, cool down to 60 ℃ and discharge, and the acrylic resin containing epoxy with a solid content of 65% can be obtained; the glass transition temperature of the above-mentioned r...

Embodiment 2

[0040] What is different from Embodiment 1 is:

[0041] In the first step, add 27% butyl acetate into a three-necked flask and heat it to 82°C, then accurately weigh 1.8% AIBN, 0.5% chain transfer agent, 26.745% MMA, 3.125% HPA, 20.13% 2-EHA, 12.5% GMA and 3.5% butyl acetate were mixed and dissolved, then added dropwise into a three-necked flask, and the dropping time was controlled to be 4 hours. After the dropwise addition was complete, the temperature was raised to 85°C and kept for 5 hours, and then 0.2% g AIBN and 4.5 %g butyl acetate, continue to keep warm for 1 hour, cool down to 60°C and discharge, and then the acrylic resin containing epoxy with a solid content of 65% can be obtained; the glass transition temperature of the above resin is about 10°C.

Embodiment 3

[0043] The difference from Example 1 is that

[0044] In the first step, add 27% butyl acetate into a three-necked flask and heat it to 82°C, then accurately weigh 1.8% AIBN, 0.5% chain transfer agent, 30.05% MMA, 3.125% HPA, 16.825% 2-EHA, 12.5% GMA and 3.5% butyl acetate were mixed and dissolved, then added dropwise into a three-necked flask, and the dropping time was controlled to be 4 hours. After the dropwise addition was complete, the temperature was raised to 85°C and kept for 5 hours, and then 0.2% g AIBN and 4.5 %g butyl acetate, continue to keep warm for 1 hour, cool down to 60°C and discharge, and then the acrylic resin containing epoxy with a solid content of 65% can be obtained; the glass transition temperature of the above resin is about 20°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com