Moving and rotating mechanism and cloth cutting device for cotton textile production

A technology of rotating mechanism and cutting device, which is applied in the cutting of textile materials, textiles and papermaking, etc. It can solve the problems of poor cutting effect, low cutting efficiency, and difficulty in maintaining the linearity of cutting, so as to improve efficiency and achieve good cutting effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to facilitate understanding of the present invention, the present invention will be described more fully described with reference to the related drawings. The preferred embodiment of the present invention is given in the drawings. However, the present invention can be implemented in a variety of different forms, and is not limited to the embodiments described herein. Conversely, the purpose of providing these embodiments is to make a more thorough understanding of the disclosure of the present invention.

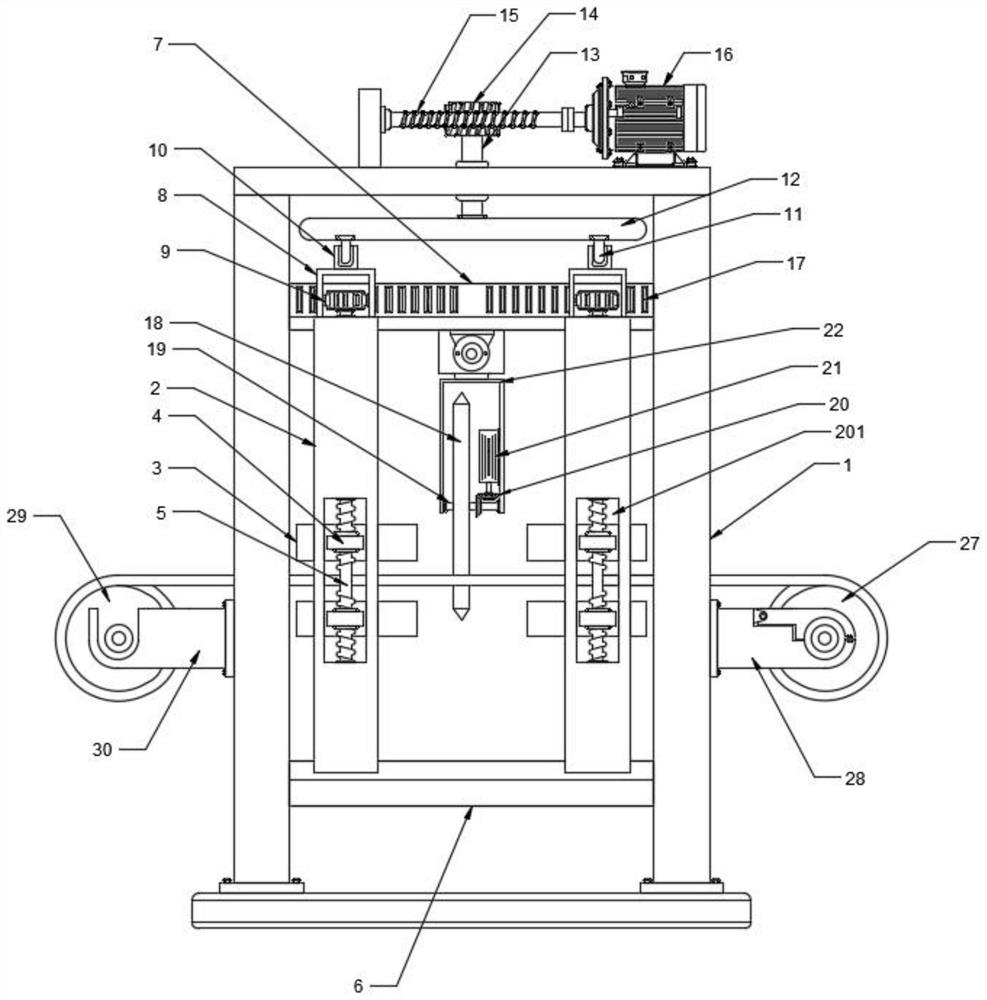

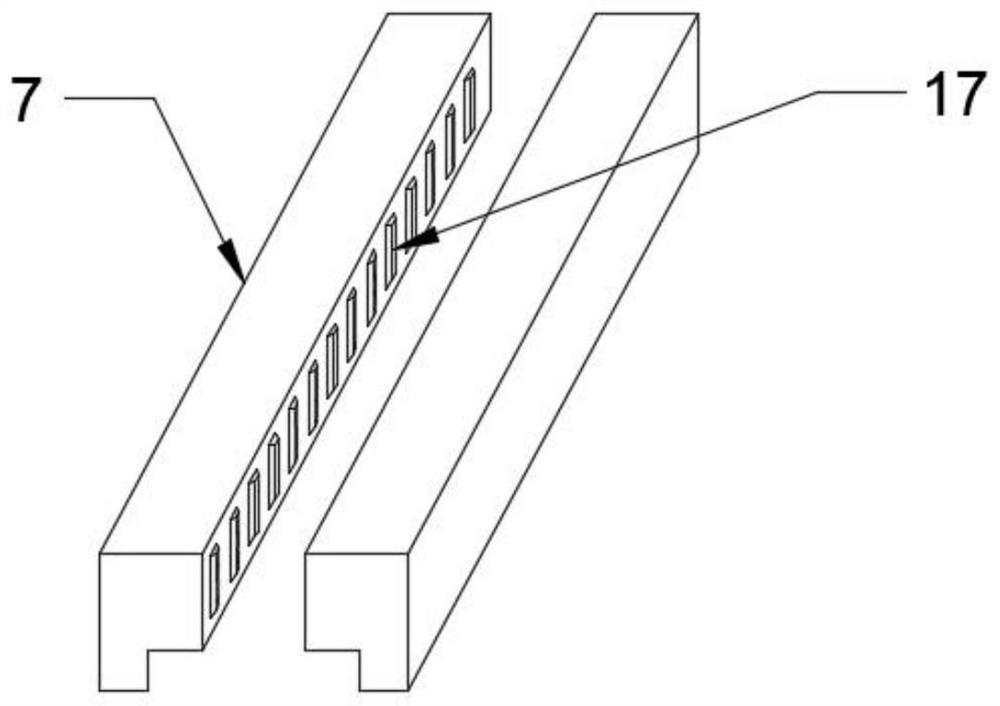

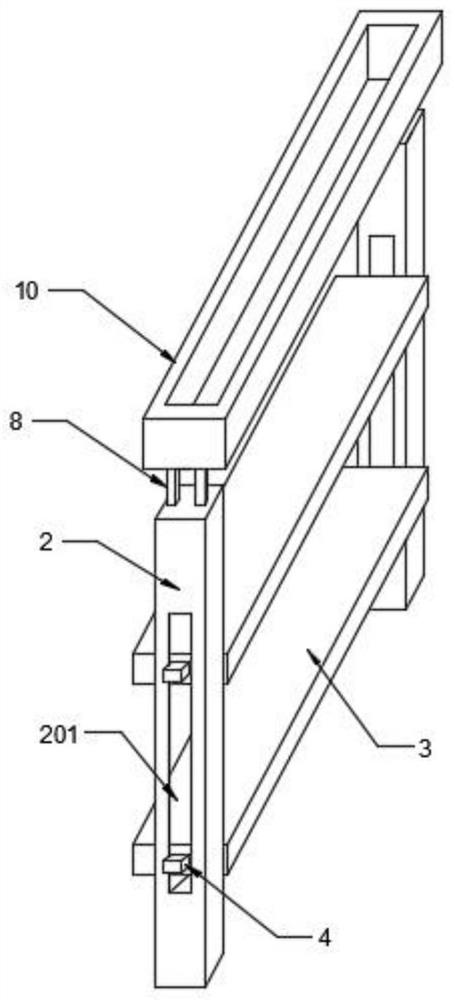

[0026] See Figure 1 ~ 4 In one embodiment of the present invention, a moving rotation mechanism includes a mounting frame 1 and two sets of clamp assemblies disposed inside the mounting frame 1, the clamp assembly including a front and rear symmetrical settings. Group moving plate 2, the upper end card is attached to the upper rail 7 and the upper rail 7 slides; the moving plate 2 is fixed to the connecting frame 8, the connecting frame 8 fixes a longitudinal sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com