Auxiliary device for chemical fertilizer production

An auxiliary device, a technology for chemical fertilizers, applied in chemical instruments and methods, chemical/physical processes, mixers with rotary stirring devices, etc. The effect of improving the quality of the finished product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

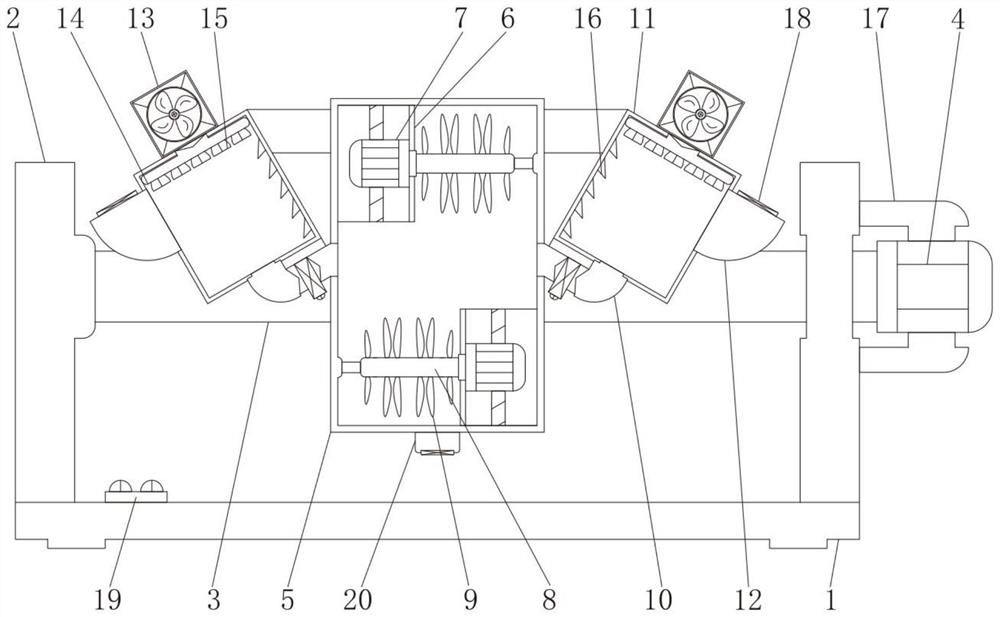

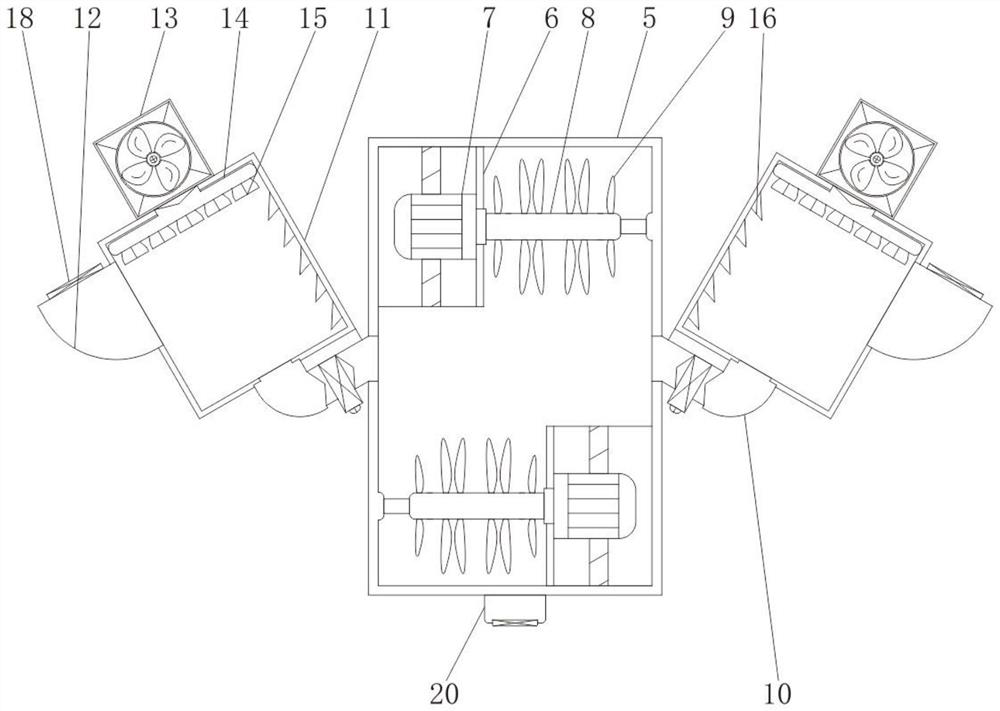

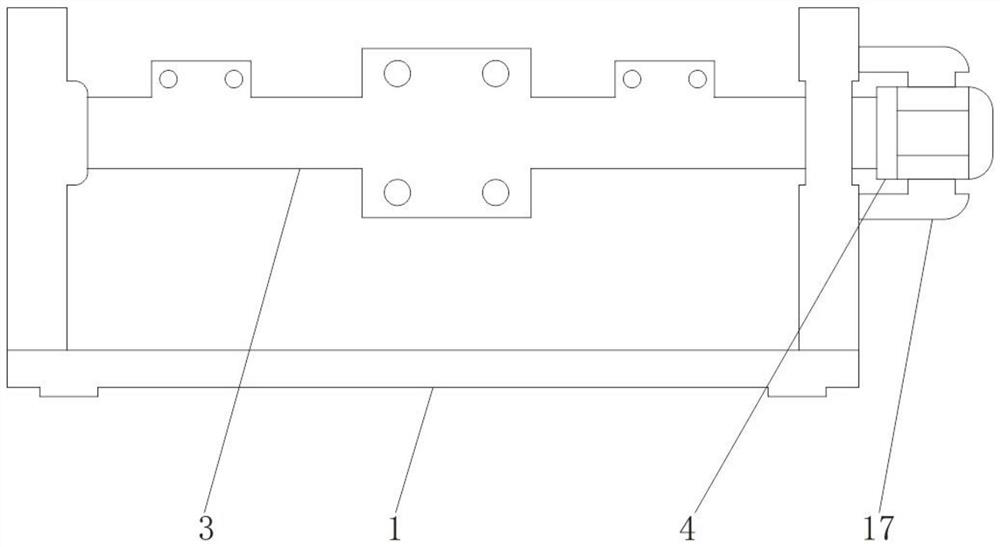

[0021] see Figure 1-3 , the present invention provides the following technical solutions: an auxiliary device for chemical fertilizer production, comprising a load-bearing chassis 1, the top center of the left and right ends of the load-bearing chassis 1 are vertically fixedly connected with a load-bearing plate 2, and the right side of the left load-bearing plate 2 is connected through a rotating shaft. There is a drive bracket 3, the right end of the drive bracket 3 is horizontally fixedly connected with a drive motor 4, and the central rear side of the drive bracket 3 is fixedly connected with a main operation box 5 by bolts, and the left top and right bottom of the main operation box 5 are respectively fixedly connected with a motor The casing 6 and the inside of the motor casing 6 are respectively fixedly connected with a stirring motor 7 through a support rod, the outer end of the stirring motor 7 is fixedly connected with a mixing rod 8, and the center of the left and r...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap