Numerical control machine tool edge folding mechanism for metal plate machining

A technology for CNC machine tools and metal sheets, applied in metal processing equipment, manufacturing tools, feeding devices, etc., can solve the problems of reducing work efficiency, wasting time, unable to automatically adjust the folding position, etc., to improve the folding efficiency and folding. good edge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

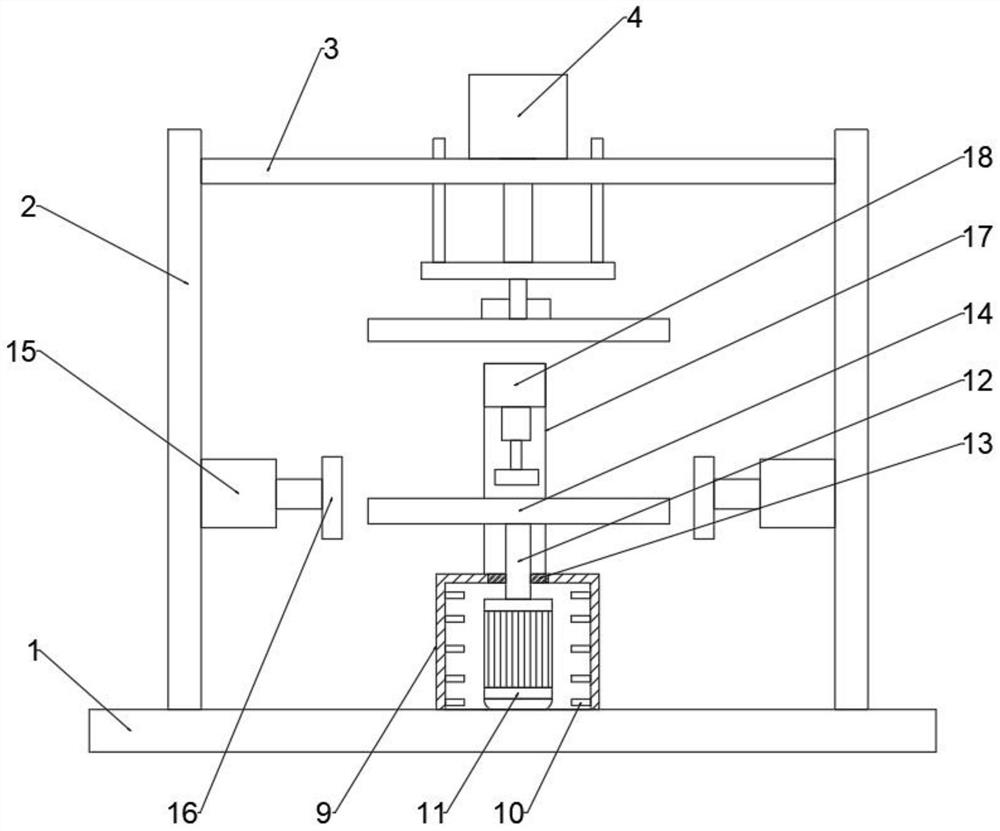

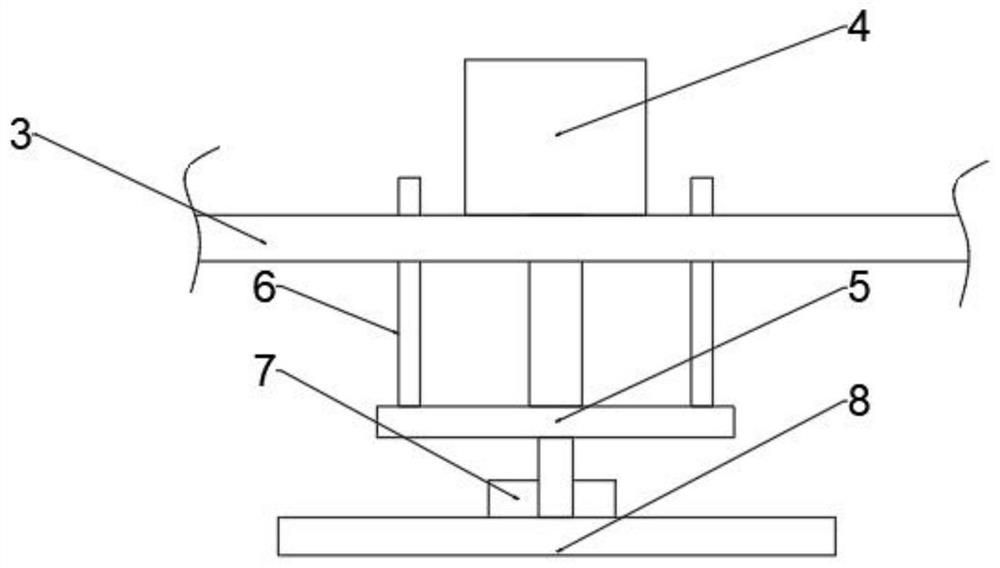

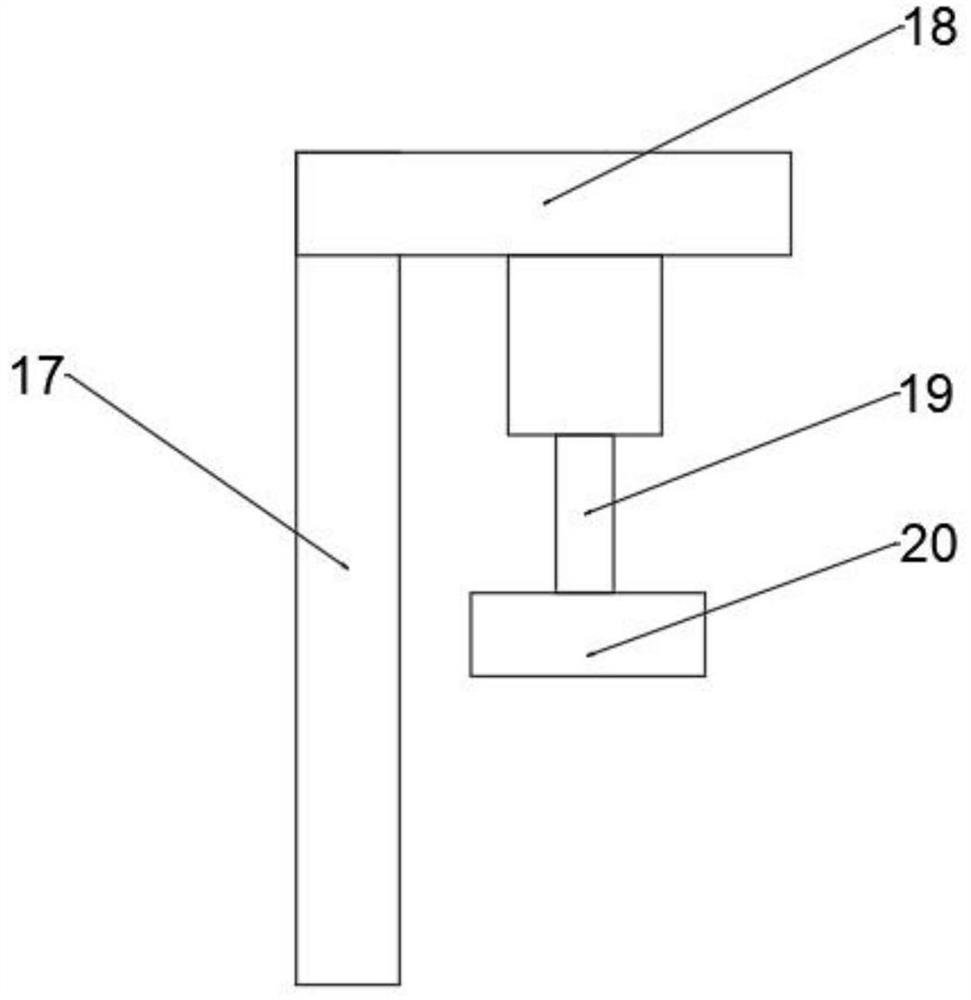

[0021] Embodiment one, by figure 1 , figure 2 and image 3 Given, the present invention includes a base 1, a support frame 2 is connected to both sides of the upper end of the base 1, a horizontal plate 3 is fixedly connected to one side of the upper part of the support frame 2, and a first hydraulic cylinder 4 is connected to the middle part of the upper end of the horizontal plate 3. The output end of the cylinder 4 runs through the horizontal plate 3, the output end of the first hydraulic cylinder 4 is connected with a partition 5, both sides of the upper end of the partition 5 are connected with round rods 6, and the middle part of the lower end of the partition 5 is rotatably connected with the first bearing 7, the first The lower end of the bearing 7 is connected with the first pressure plate 8, the middle part of the upper end of the base 1 is connected with the casing 9, the lower part of the casing 9 is connected with the motor 11, the output end of the motor 11 is ...

Embodiment 2

[0022] Embodiment 2, on the basis of Embodiment 1, the upper end of the round rod 6 runs through and extends to the upper part of one side of the horizontal plate 3 to open a through hole, the round rod 6 is located in the through hole, and the round rod 6 is slidably connected with the through hole, which is convenient Round bar 6 moves up and down.

Embodiment 3

[0023] Embodiment 3, on the basis of Embodiment 1, sound-absorbing partitions 10 are connected to both sides of the inner wall of the box body 9 to reduce noise.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com