Edge folding-in device for gripper shuttle loom

A technology of folding edge device and shuttle loom, which is applied in looms, textiles, textiles and papermaking, etc., can solve the problems of expensive equipment, waste of raw materials, complicated structure, etc., and achieve the best price performance, convenient installation and maintenance, The effect of the simple structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

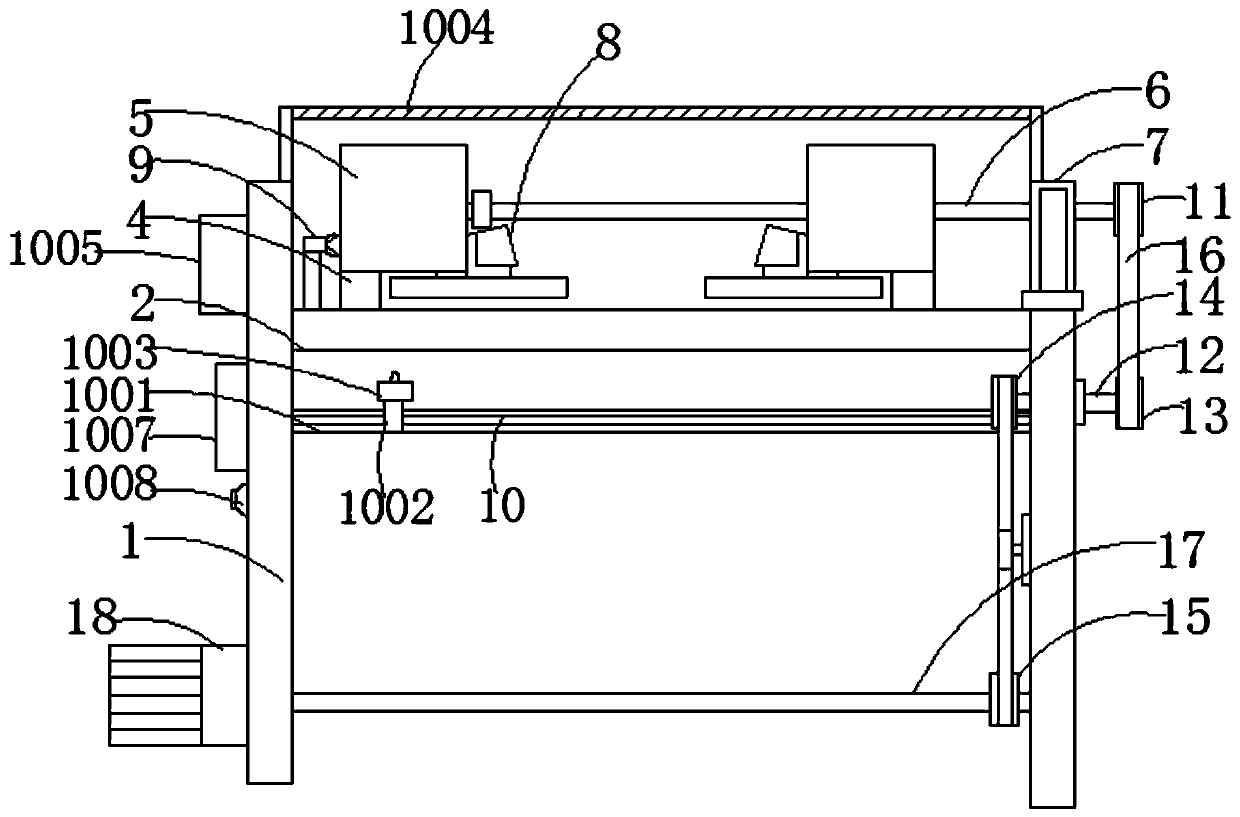

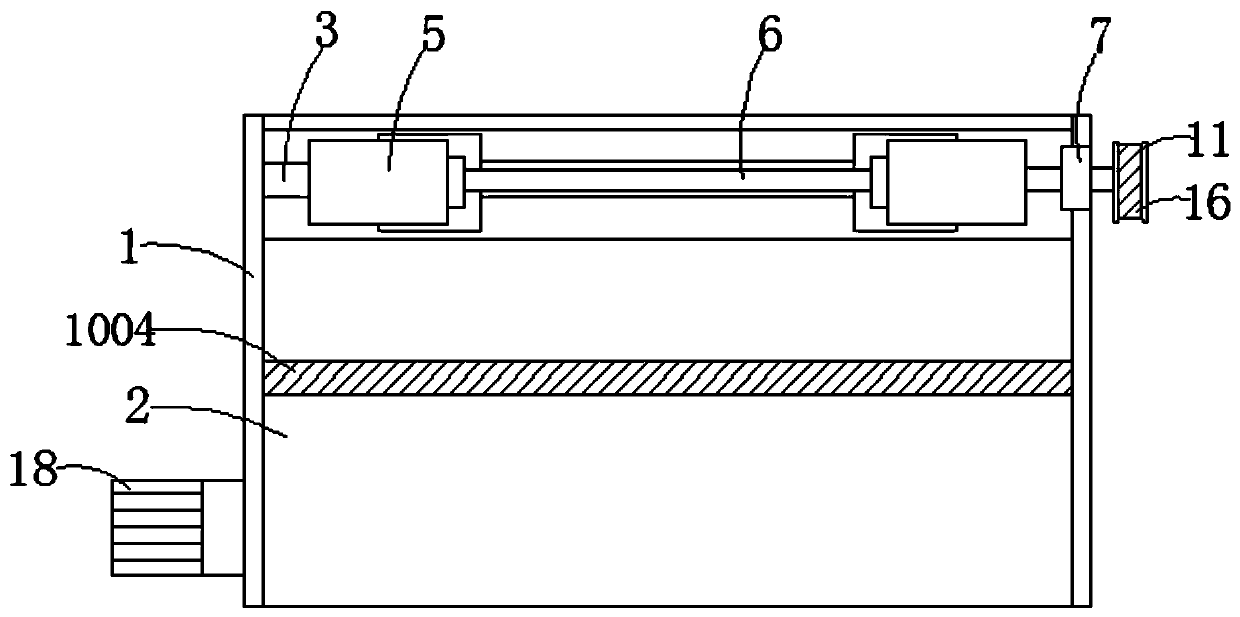

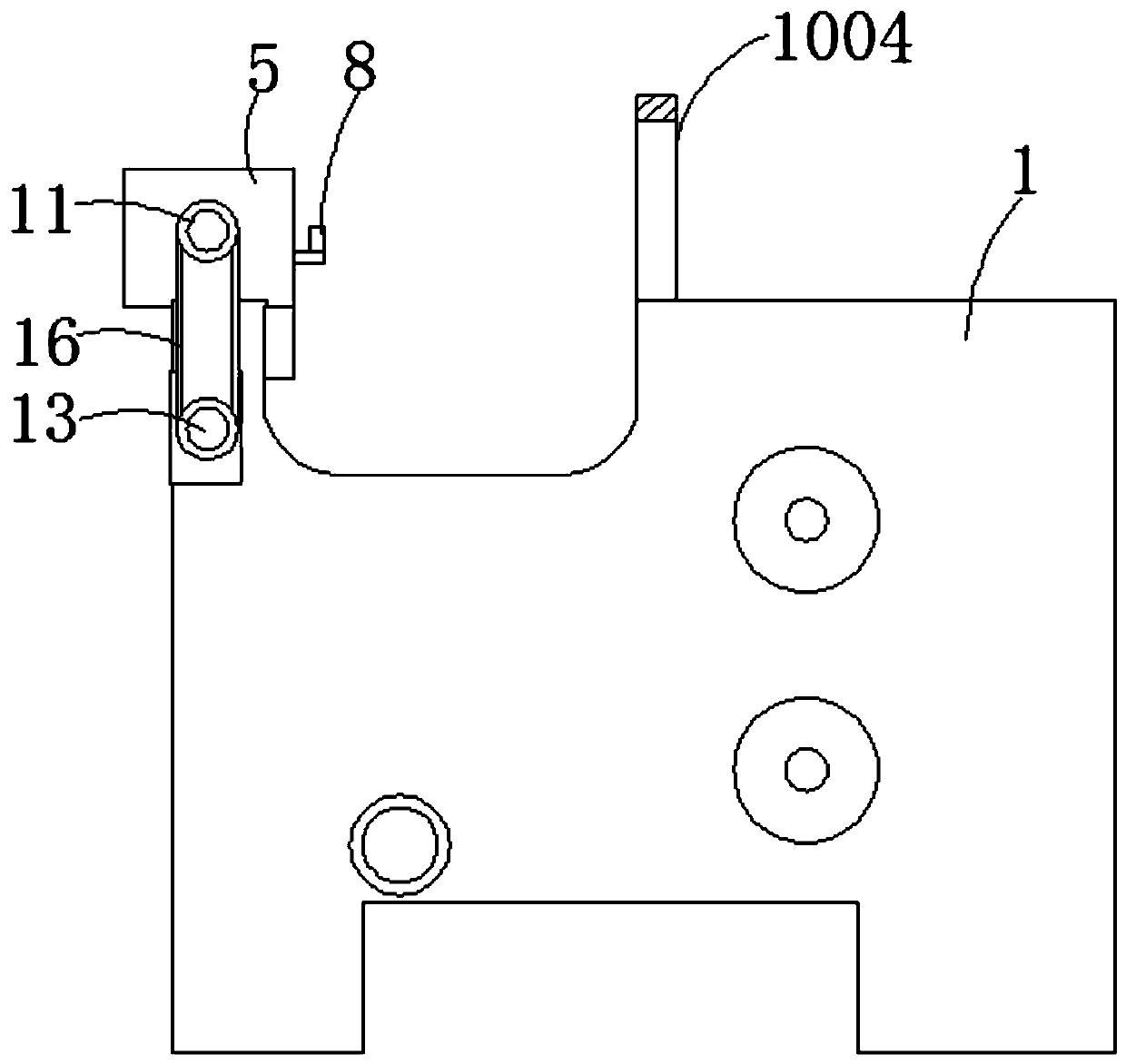

[0024] Such as Figure 1-3 As shown, a folding-in device for a projectile loom includes two parallel support plates 1 and a support platform 2, the support platform 2 is located above the support plate 1, and the upper end of the support platform 2 is provided with a sliding track 3, which slides Two moving trolleys 4 are slidingly installed on the track 3, and an edge folding machine 5 is installed on the upper end of each moving trolley 4, and a transmission shaft 6 is installed between the two edge folding machines 5, and one end of the transmission shaft 6 is rotatably connected to the edge folding machine. On the machine 5, the other end passes through the mobile trolley 4 close to the right side and is rotated and installed on the transmission shaft seat 7. The lower end of the transmission shaft seat 7 is fixedly installed on the support platform 2, and the opposite surfaces of the two edge folding machines 5 are installed with Crochet needle 8, bending type scissors 9 ...

Embodiment 2

[0028] Such as Figure 1-4 As shown, a folding-in device for a projectile loom includes two parallel support plates 1 and a support platform 2, the support platform 2 is located above the support plate 1, and the upper end of the support platform 2 is provided with a sliding track 3, which slides Two moving trolleys 4 are slidingly installed on the track 3, and an edge folding machine 5 is installed on the upper end of each moving trolley 4, and a transmission shaft 6 is installed between the two edge folding machines 5, and one end of the transmission shaft 6 is rotatably connected to the edge folding machine. On the machine 5, the other end passes through the mobile trolley 4 close to the right side and is rotated and installed on the transmission shaft seat 7. The lower end of the transmission shaft seat 7 is fixedly installed on the support platform 2, and the opposite surfaces of the two edge folding machines 5 are installed with Crochet needle 8, bending type scissors 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com