Work clothes folding device in work clothes folding machine

The technology of a work clothes folding machine and a folding device is applied in the directions of laundry room devices, folders, washing devices, etc., which can solve the problems of inability to guarantee the consistency of folding quality, high labor intensity, and increase costs, and achieve automatic folding operations and improve The effect of folding efficiency and small labor input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

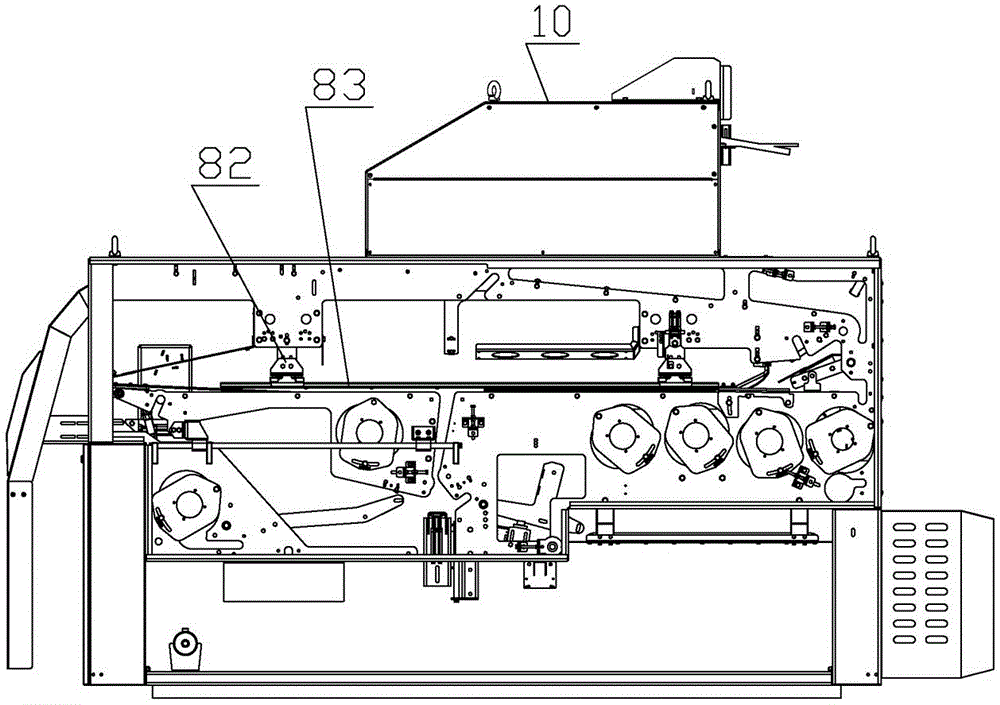

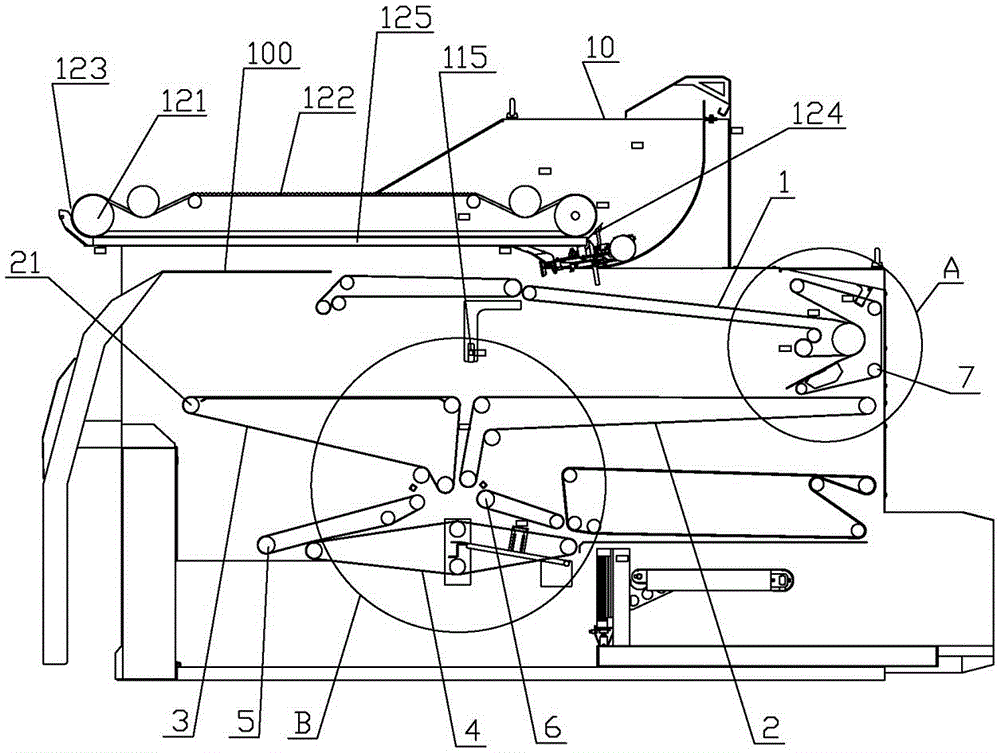

[0024] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

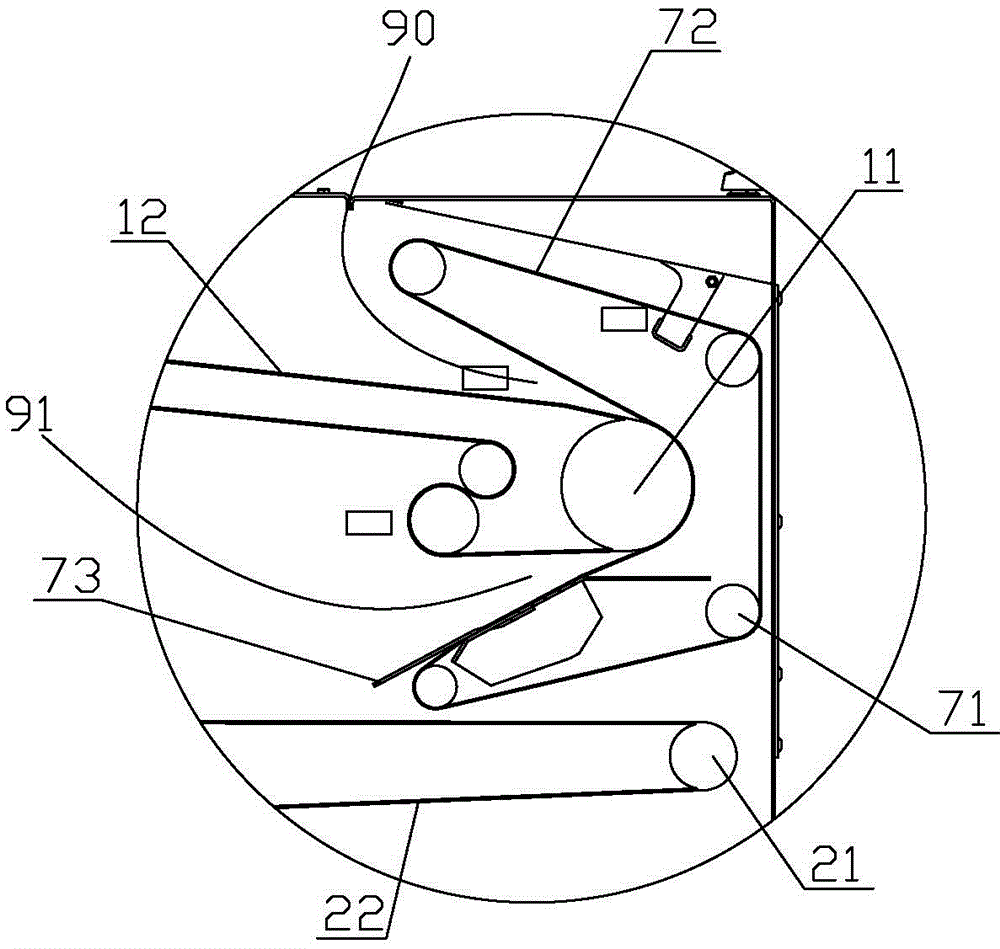

[0025] Such as figure 2 , Figure 5 and Figure 6 As shown, the work clothes folding device in the work clothes folding machine according to the present invention is provided with a sleeve folding device capable of cross-folding the two sleeves of the work clothes on the back of the work clothes at the feeding place of the frame body 10 100. The structure of the sleeve folding device 100 described in this embodiment is as follows: a garment support board 101 is provided at the feeding place of the frame body 10, and the sleeves on both sides of the work clothes are laid flat on the garment support board 101. Both sides of the garment supporting board 101 are naturally drooping downwards. Above the garment supporting board 101, there is a seventh delivery device that hooks the hanger hook and pulls the han...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com