Air floating garbage winnowing machine

An air separator and air flotation technology, which is applied in the separation of solids from solids by air flow, solid separation, chemical instruments and methods, etc., can solve the problems of poor material sorting quality and short wind exposure time. The effect of easy processing, few moving parts and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the embodiments, but the design concept of the present invention is not limited thereto, and any non-substantial changes to the present invention by using this concept should belong to the behavior of violating the protection scope of the present invention.

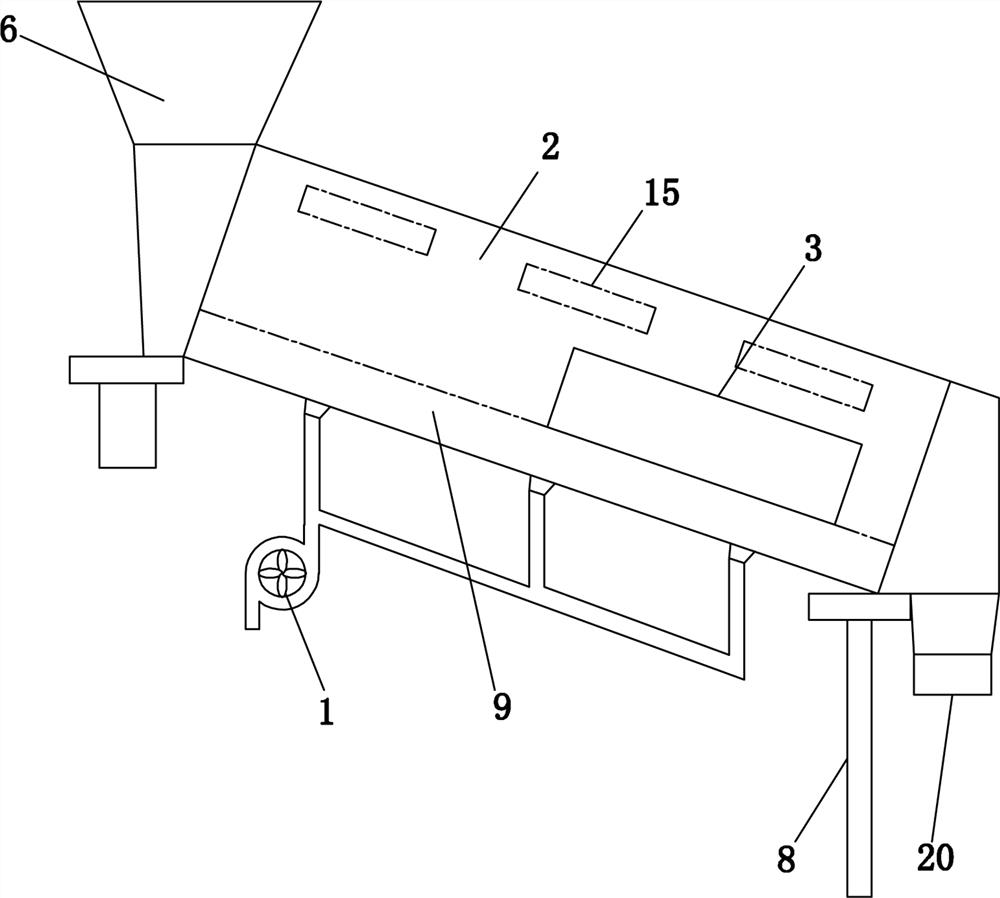

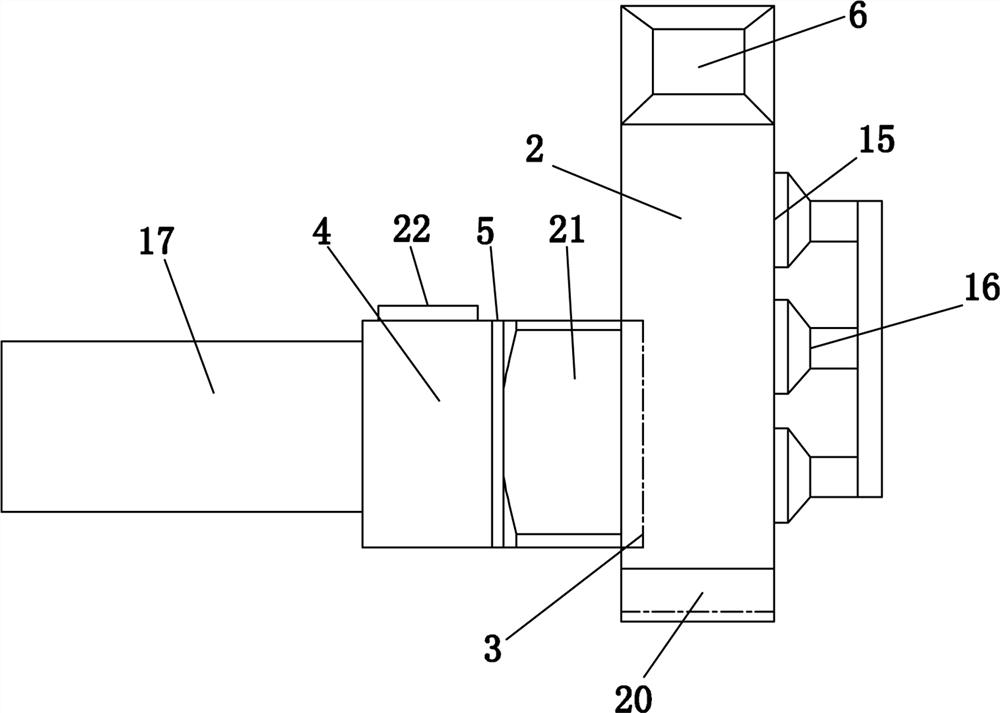

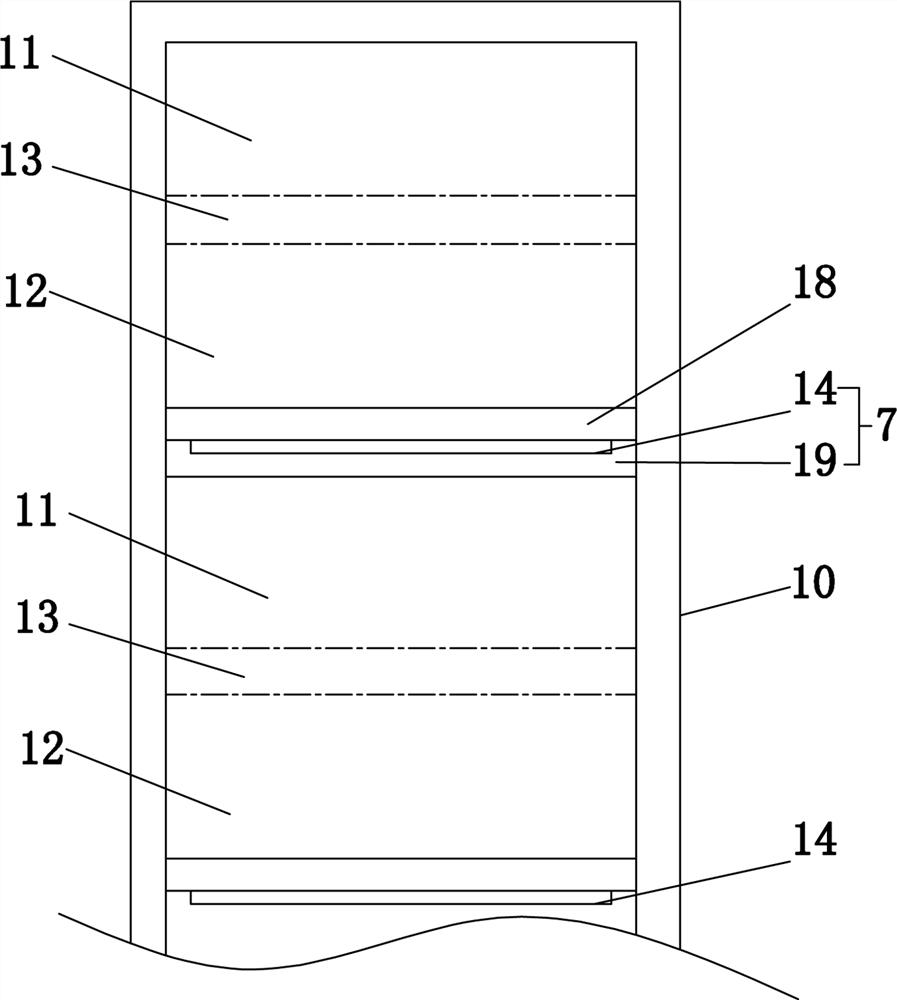

[0034] The present invention relates to an air flotation type garbage winnowing machine. During the process of sliding down the air flotation bed, the materials are first lifted by the high-pressure wind of the air flotation fan 1 in the vertical direction, and the lighter materials are suspended in the air to realize the preliminary separation of light and heavy materials, and then Suspended materials are blown by horizontal wind force to further realize the separation of light and heavy materials. After several times of air flotation and blowing, the effective separation of light and heavy materials is realized. Lighter materials en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com