Liquid distributor, multi-stage efficient distributor and washing liquid spraying method

A technology of liquid distributor and distributor, applied in the field of washing liquid spraying, which can solve the problems that the uniformity of the absorbent and the integrity of the coverage cannot be guaranteed, the nozzles cannot achieve the best spraying effect at the same time, and the pressure change of the washing liquid is ignored. , to achieve the effects of simple structure, increased kinetic energy, and improved washing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

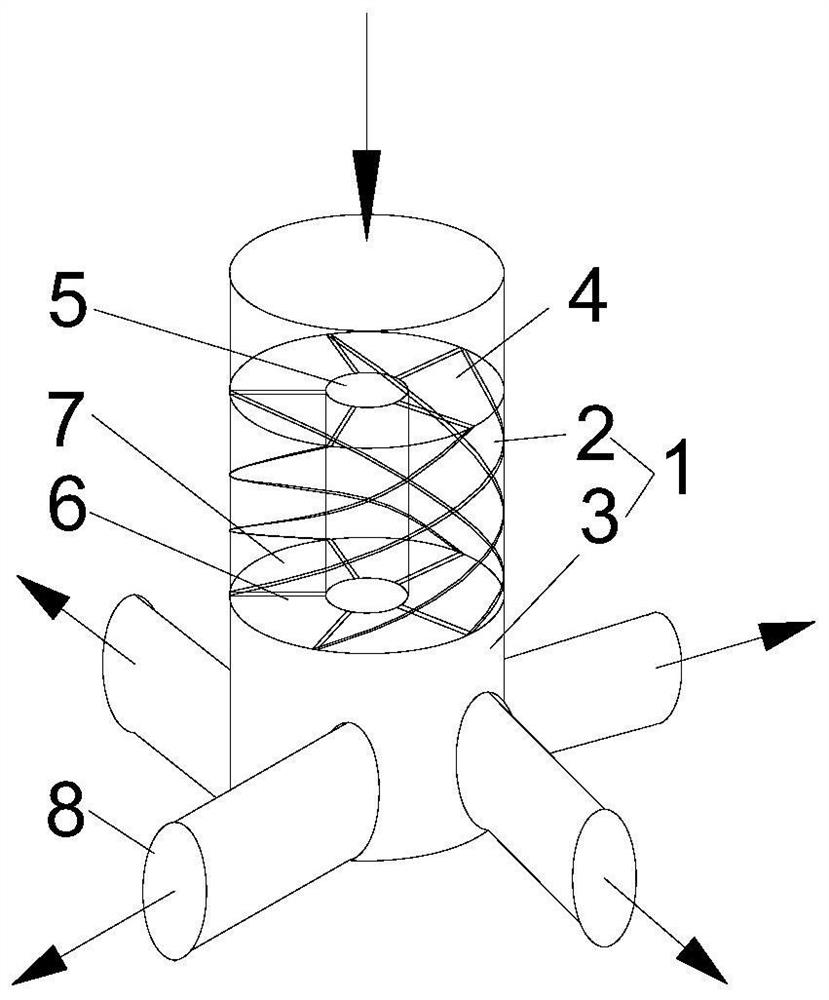

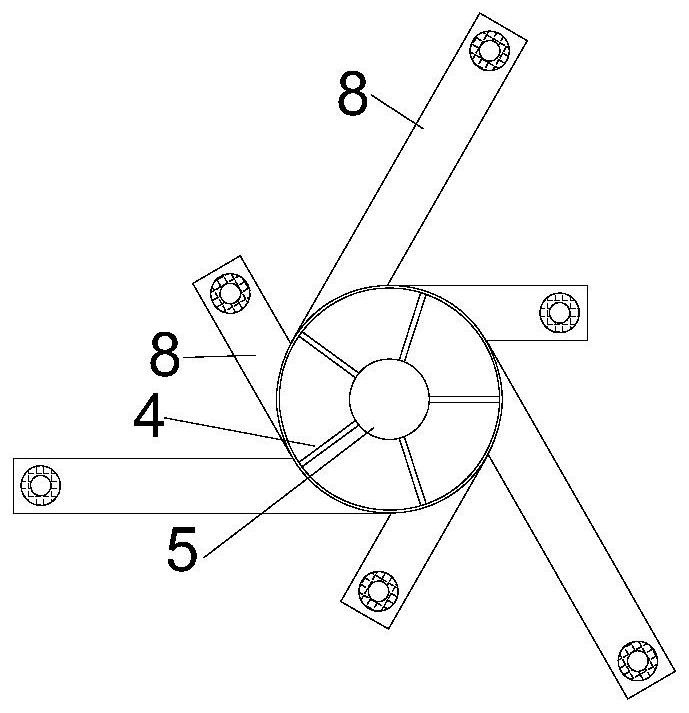

[0042] The present invention provides a liquid dispenser, see figure 1 , including a vertical cylinder 1 with a bottom seal, the cylinder 1 includes an upper feed chamber 2 and a lower distribution chamber 3, the inner wall of the feed chamber 2 is provided with a plurality of helical blades 4 from top to bottom, and the helical blades 4 The inner edge is connected to the vertical fixing column 5 in the middle. In order to reduce the weight, it is better to set the inside of the fixing column 5 as hollow. The distribution chamber 3 includes a plurality of partitions 6, the partitions 6 divide the distribution chamber 3 into a plurality of independent chambers 7, each independent chamber 7 has a through hole on its outer wall, and an outlet pipe 8 is connected to the through hole. The liquid enters from the top of the feeding chamber 2 and is accelerated by the spiral blade 4 to be distributed to each independent chamber 7 . Preferably, the volume of each independent chamber 7...

Embodiment 2

[0044] A high-efficiency distributor (two-stage) suitable for liquid spray, see Figure 4 and Figure 5 , including the above-mentioned liquid distributor as the central distributor 100 is also a first-level distributor, each outlet pipe 8 is connected to a second-level distributor 200 through a connecting pipe 12, and the central distributor 100 located in the middle is higher than the surrounding first-level distributors. In the secondary distributor 200, all the outlet pipes 8 are arranged tangentially along the outer wall of the distribution chamber 3, and the outlet pipes 8 of the second-stage distributor 200 on the lower floor are connected to the vertical extension pipe 9 downward, and the vertical extension pipe The bottom of 9 is connected with nozzle 10.

[0045] preferred, see image 3 and Figure 4 , the vertically extending pipe 9 has two lengths and two or more lengths are arranged at intervals, so that the heights of the nozzles 10 can be different, so that the...

Embodiment 3

[0051] When the required spraying area is greater than 78.5m2 2 , in order to ensure the local spraying effect, the high-efficiency distributor needs to adopt a three-stage spraying arrangement, and the specific structure can be found in Figure 9 and Figure 10 . The outlet pipe of the central distributor 100 is connected to the second-stage distributor 200 through the connecting pipe 12 , and the outlet pipe of the second-stage distributor 200 is connected to the third-stage distributor 300 through the connecting pipe 12 .

[0052] The high-efficiency distributor of the present invention can precisely control the spray coverage area when the single nozzle 10 and the multi-nozzle 10 are combined, thereby ensuring high-efficiency washing and strong adaptability. Using high-efficiency distributors in spray washing equipment (such as spray towers) and rationally arranging the distance between nozzles 10 can improve the gas washing efficiency.

[0053] The following specific e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Helix angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com