A waste cloth crushing and recycling machine

A recycling machine and fabric technology, applied in grain processing, etc., can solve problems such as easy winding, achieve the effect of preventing waste wire from winding and ensuring crushing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

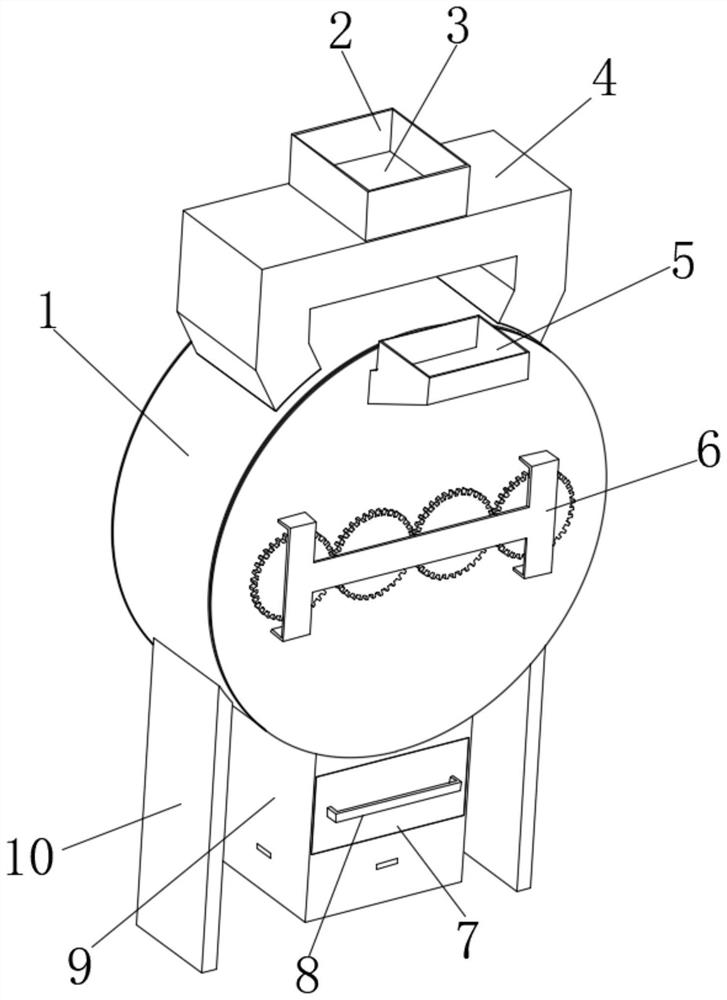

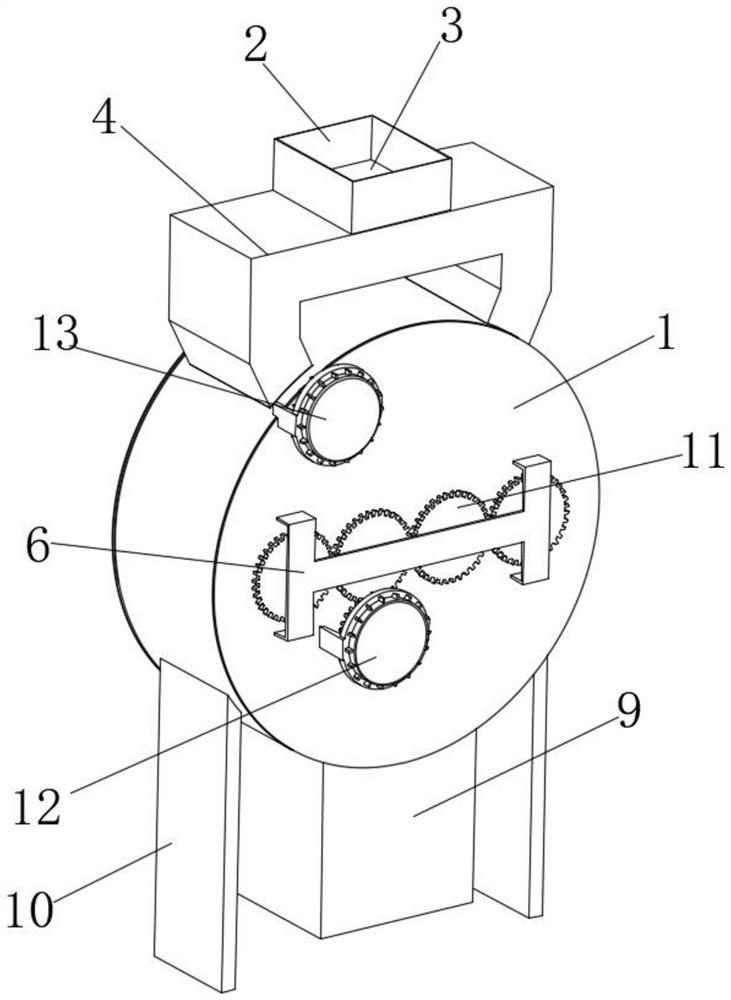

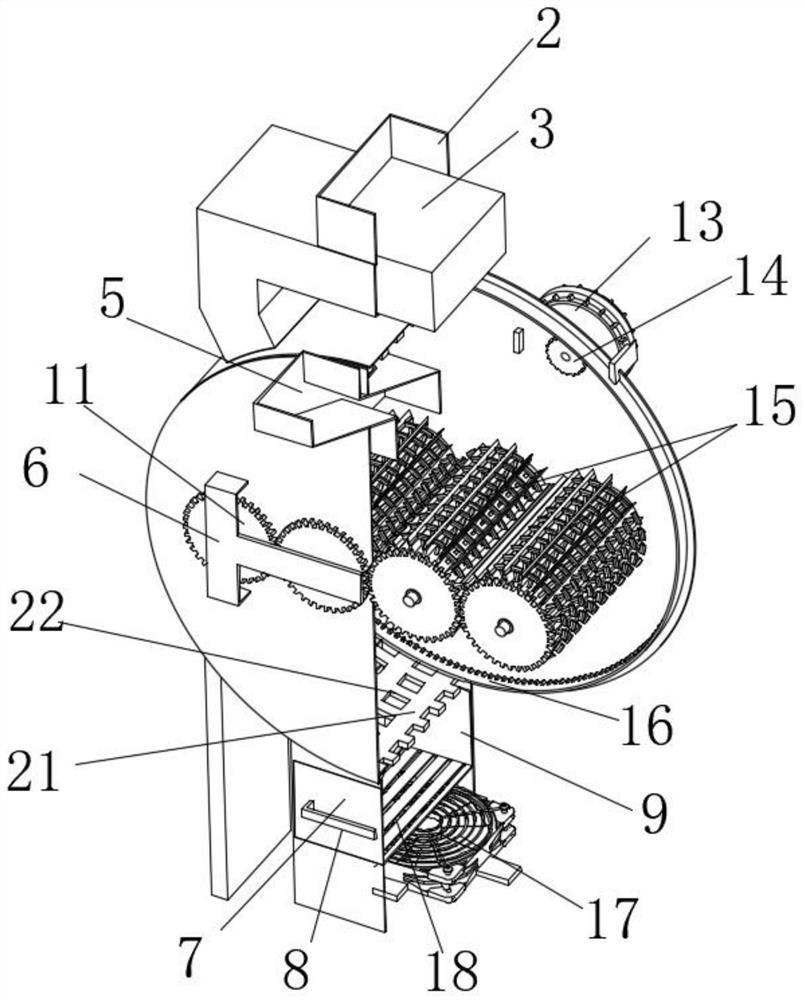

[0027] Such as Figure 1-Figure 7 The waste cloth crushing and recycling machine shown includes a casing 1, the inner wall of the casing 1 is provided with a rotating cylinder 21 that is slidably fitted therewith, the rotating cylinder 21 is evenly distributed with third through grooves 22, and the side wall of the casing 1 is provided with a drive Rotating drum 21 is a rotating mechanism that rotates around its central axis. The rotating mechanism includes a second motor 13. The second motor 13 is fixedly mounted on the outer wall of the housing 1 through a mounting seat. The end of the output shaft of the second motor 13 is coaxially connected with a drive gear. 14 , the driving gear 14 meshes with the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com