Mammary gland bracket

A breast and electric push rod technology, applied in the field of medical equipment, can solve the problems of not being able to adjust the distance between massage cups, not being able to fold and store, and attaching dust, etc., to achieve the effects of expanding practicability, reducing cleaning times, and facilitating storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

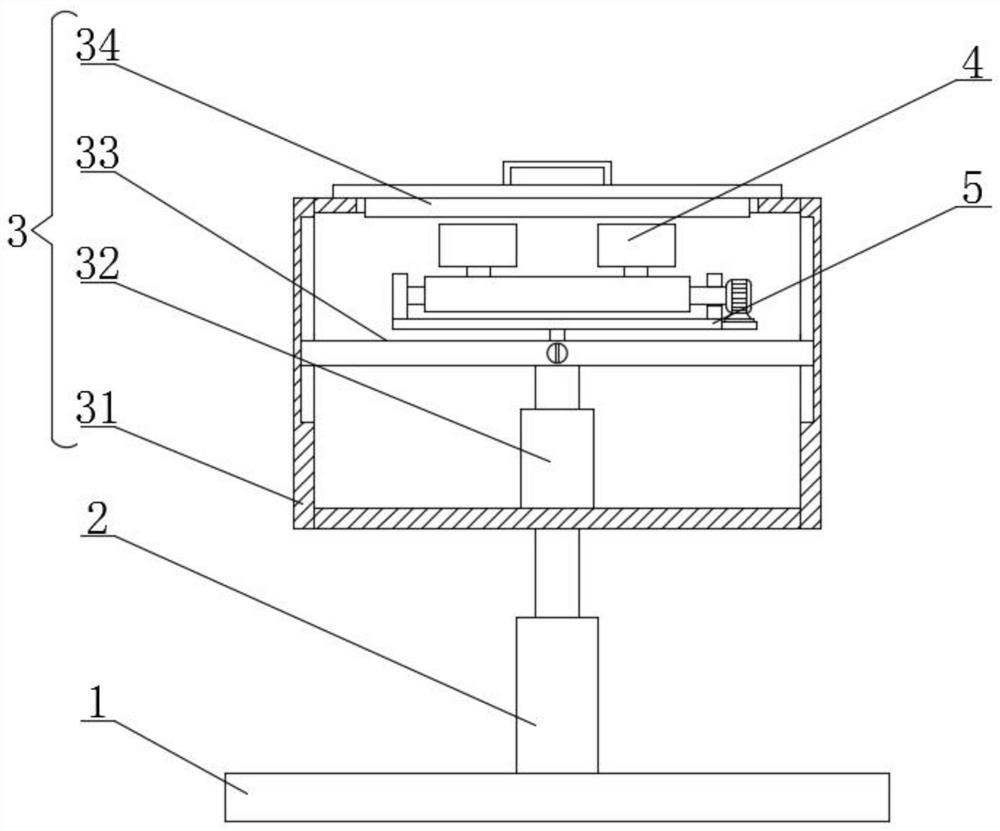

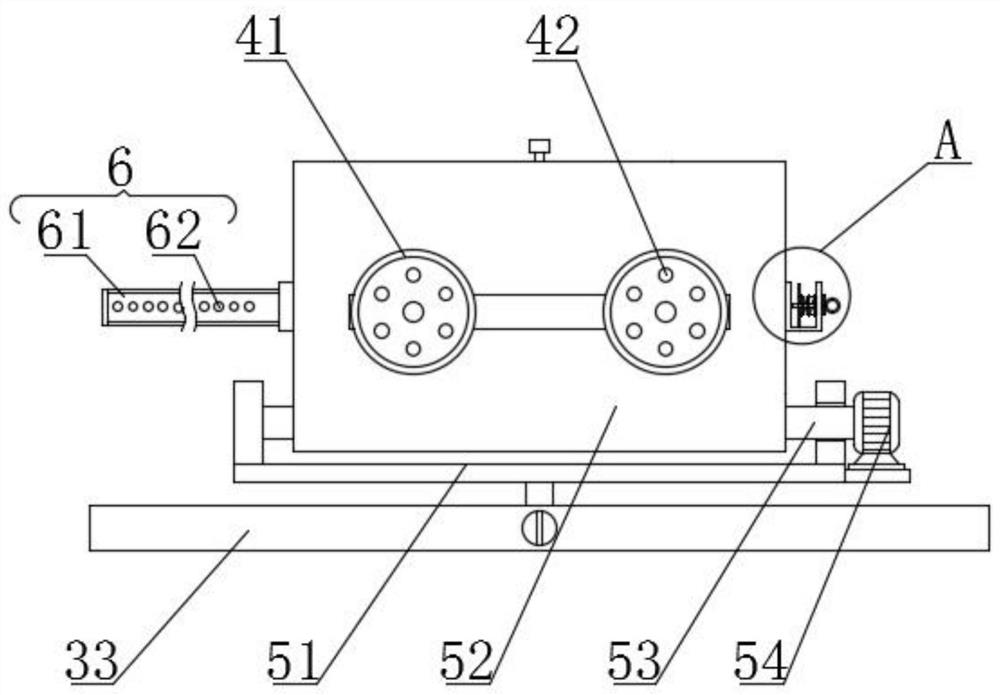

[0032] see Figure 1-8 , the present invention provides a technical solution: a mammary gland bracket, a fixed plate 1; a first electric push rod 2, the first electric push rod 2 is fixedly welded at the center of the top surface of the fixed plate 1; a storage mechanism 3, The storage mechanism 3 includes a storage frame 31, a second electric push rod 32, a placement plate 33 and a sealing cover 34. The top of the first electric push rod 2 is fixedly welded with the storage frame 31, and the bottom of the inner wall of the storage frame 31 is A second electric push rod 32 is fixedly welded in the center, and a placement plate 33 is fixedly welded on the top of the second electric push rod 32, and a sealing cover 34 is connected to the top of the storage frame 31; the moving mechanism 7, the placement The inside of the plate 33 is fixedly equipped with a moving mechanism 7; a rotating mechanism 5, the rotating mechanism 5 includes a mounting seat 51, a rotating plate 52, a fix...

Embodiment 2

[0034] As a preferred solution of Embodiment 1, the connecting device 83 includes a fixed sleeve 831, a sliding plate 832, a second spring 833, a fixed frame 834, an insertion rod 835 and a push rod 836, and the surface of the second threaded sleeve 85 A fixed sleeve 831 is fixedly welded. The end of the fixed sleeve 831 away from the second threaded sleeve 85 passes through the rotating plate 52 and extends to the outside of the rotating plate 52. The top surface of the fixed sleeve 831 extending to the outside of the rotating plate 52 is fixedly welded with A fixed frame 834, a sliding plate 832 is slidably connected between the inner walls of the fixed frame 834, and a second spring 833 is fixedly welded between the top of the sliding plate 832 and the inner wall top of the fixed frame 834, and the sliding plate 832 A push rod 836 is fixedly welded at the center of the bottom, the bottom of the push rod 836 passes through the fixed frame 834 and the fixed sleeve 831 and exte...

Embodiment 3

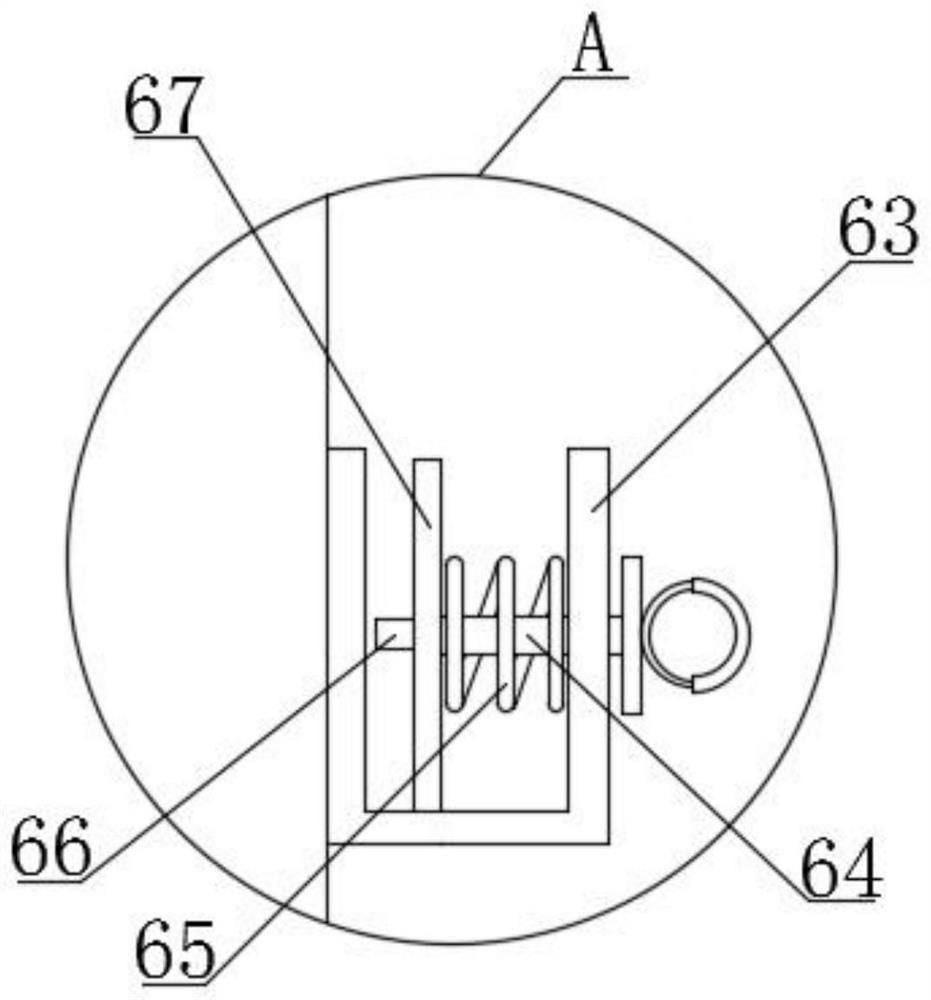

[0036] As a preferred solution of Embodiment 1, the side wall is fixedly installed with a limit mechanism 6, and the limit mechanism 6 includes a strap 61, a through hole 62, a limit frame 63, a sliding rod 64, a first spring 65, a limit A position column 66 and a limit plate 67, a strap 61 is fixedly installed in the center of one side wall of the rotating plate 52, and a plurality of through holes 62 are provided in the inside of the strap 61, and the side of the rotating plate 52 The wall and the side away from the strap 61 are fixedly welded with a limit frame 63, and the center of the side of the limit frame 63 away from the rotating plate 52 is movably inserted with a sliding rod 64, and the slide rod 64 is located at the limit frame 63. One end of the interior is fixedly welded with a limiting plate 67, and the end of the limiting plate 67 away from the sliding rod 64 is fixedly welded with a limiting column 66 that is compatible with the through hole 62, and the surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com