Lithium battery residual capacity management method and system

A technology of residual capacity and management method, applied in the field of lithium battery residual capacity management method and management system, can solve problems such as insufficient capacity, residual capacity detection and management, affecting user experience, etc., to improve user experience and facilitate safety management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for managing residual capacity of a lithium battery, comprising the following steps:

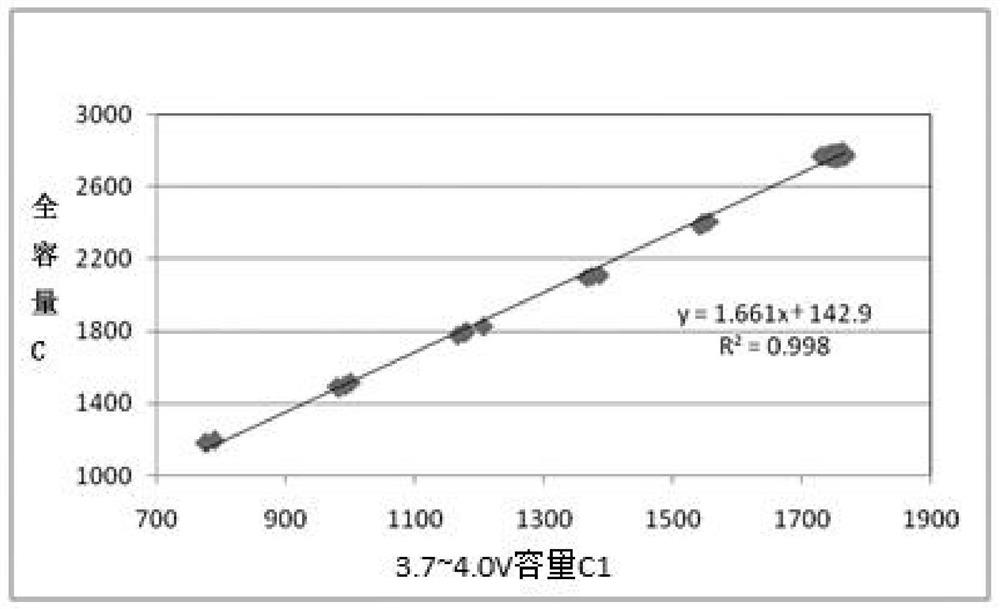

[0030] S1, take a number of batteries of the same type as the batteries of the electronic product under test, charge a number of said batteries, select two voltage points 3.7V and 4.0V during the charging process of each battery, and calculate the voltage between 3.7V and 4.0V The charge capacity C 1 , with the charging capacity C of several batteries 1 is the abscissa, taking the full capacity C of several batteries as the ordinate, and performs linear fitting, such as figure 1 As shown, the formula C=1.661C is obtained 1 +142.9;

[0031] S2, through the power management system of the electronic product under test, obtain the charging capacity C between the voltage points of 3.7V and 4.0V when the battery of the electronic product under test is charged 1 is 2262mAh, the remaining battery capacity C is calculated by the formula obtained in step S1 残余 , C 残余 =1.661C 1 +...

Embodiment 2

[0035] A method for managing residual capacity of a lithium battery, comprising the following steps:

[0036] S1, take a number of batteries of the same type as the batteries of the electronic product under test, charge a number of said batteries, select two voltage points 3.7V and 4.0V during the charging process of each battery, and calculate the voltage between 3.7V and 4.0V The charge capacity C 1 , with the charging capacity C of several batteries 1 is the abscissa, taking the full capacity C of several batteries as the ordinate, and performs linear fitting, such as figure 1 As shown, the formula C=1.661C is obtained 1 +142.9;

[0037] S2, through the power management system of the electronic product under test, obtain the charging capacity C between the voltage points of 3.7V and 4.0V when the battery of the electronic product under test is charged 1 is 1841mAh, calculate the remaining battery capacity C by the formula obtained in step S1 残余 , C 残余 =1.661C 1 +142....

Embodiment 3

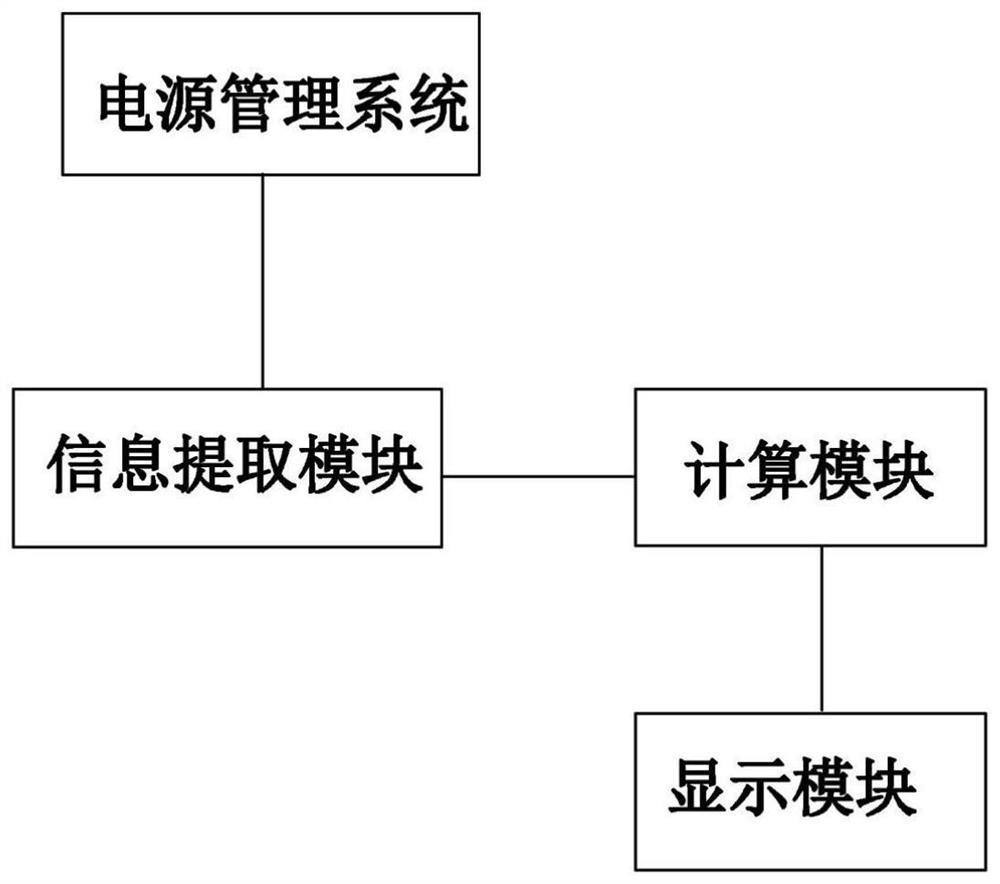

[0041] Such as figure 2 As shown, a lithium battery residual capacity management system includes:

[0042] The information extraction module is connected with the power management system of the electronic product under test, and is used to extract the battery charging data of the electronic product;

[0043] The calculation module is connected with the information extraction and screening module, and uses the filtered charging data to perform calculations, so as to obtain the remaining battery capacity and the percentage of battery remaining capacity;

[0044] The display module is connected with the calculation module, and is used for displaying the remaining capacity of the battery and the percentage of the remaining capacity of the battery on the screen of the electronic product.

[0045] Specifically, the charging data of the rechargeable battery includes the battery at the voltage point U 1 ~ U 2 between the charging capacity and the rated capacity of the battery.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com