A fuel plate surface contamination location detection device and system

A positioning detection device and surface detection technology, applied in the field of nuclear detection, can solve the problems of low degree of automation and low detection efficiency, and achieve the effects of high degree of automation, high detection efficiency, and avoidance of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

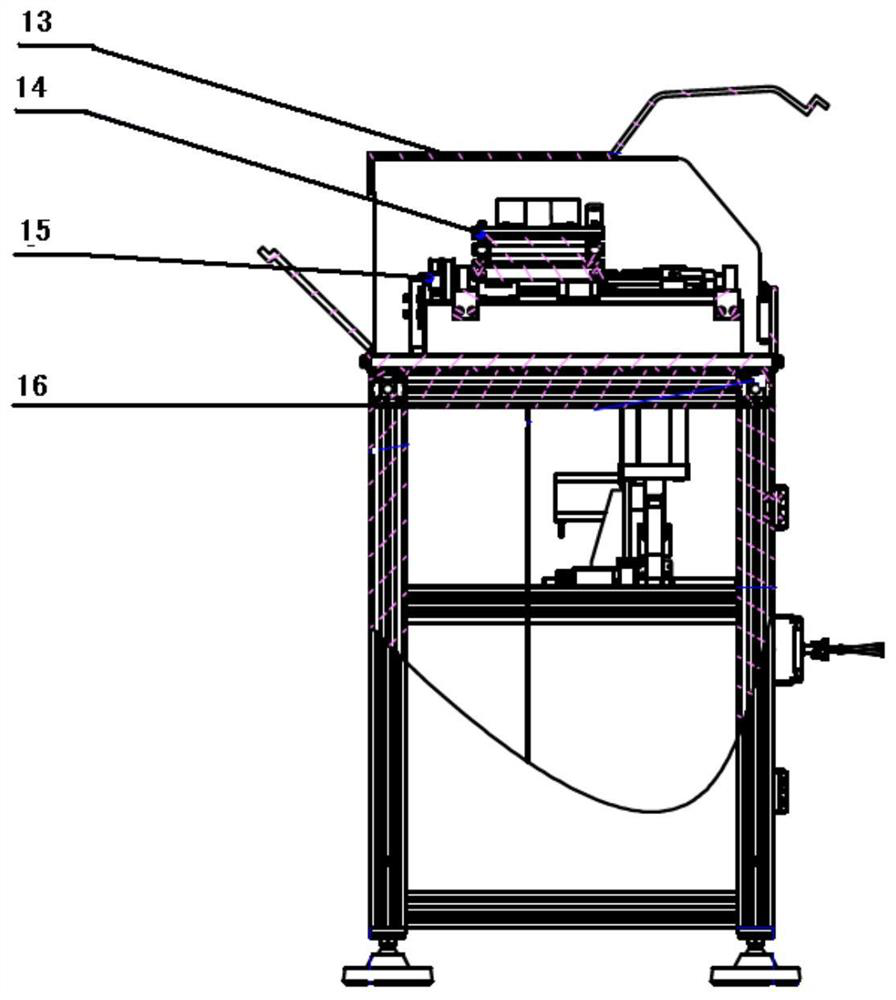

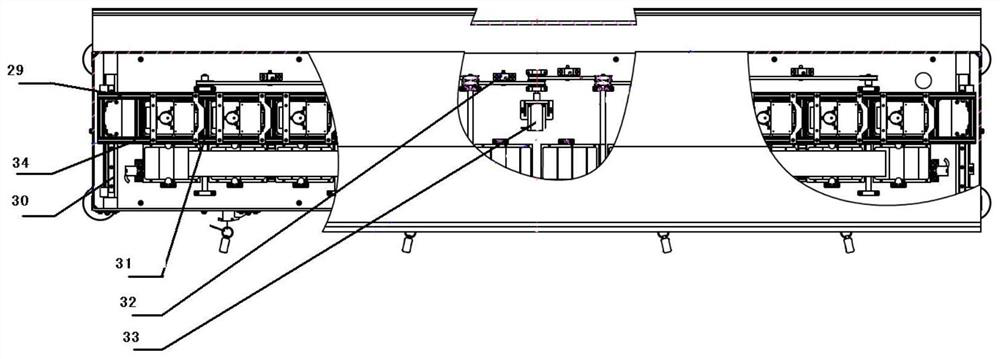

[0033] This embodiment proposes a fuel plate surface pollution location detection device, such as Figure 1-3 As shown, the fuel plate surface contamination location detection device includes: the detection device includes a shield 13, an upper surface detection unit 27, a lower surface detection unit 28, a lifting unit, a workpiece transfer unit and a support mechanism 16; wherein the shield 13 It is fixed on the support mechanism 16 and forms a cavity with the support mechanism 16 to accommodate the upper surface detection unit 27 , the lower surface detection unit 28 , the lifting unit and the workpiece transfer unit arranged on the support mechanism 16 . For the convenience of subsequent description, this embodiment refers to figure 2 front view of and image 3 In the top view of the support mechanism, the left-right direction (ie, the length direction) of the support mechanism is defined as the transverse direction, and the front-to-back direction (ie, the width directi...

Embodiment 2

[0043] Based on the fuel plate surface pollution location detection device proposed in the above embodiment 1, this embodiment proposes a fuel plate surface pollution location detection system, such as Figure 4 Said, the detection system includes a signal processing device 5, a host computer 7, a power supply device 1 and a fuel plate surface contamination location detection device 3 (that is, the fuel plate surface contamination location detection device proposed in the above-mentioned embodiment 1); the power supply device 1 Power supply for the signal processing device 5, the upper computer 7 and the fuel plate surface contamination location detection device 3 respectively; The processing means 5 are connected in communication.

[0044] Specifically, in this embodiment, the power supply device 1 adopts a regulated power supply, and the host computer adopts a computer; the regulated power supply 1 is connected to the surface pollution detection device 3 through the power co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com