Workpiece surface defect detection system

A technology for flaw detection and workpiece surface, applied in the direction of optical flaw/defect test, measuring device, material analysis through optical means, etc., can solve problems such as fuzzy distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following is a further detailed description through specific embodiments:

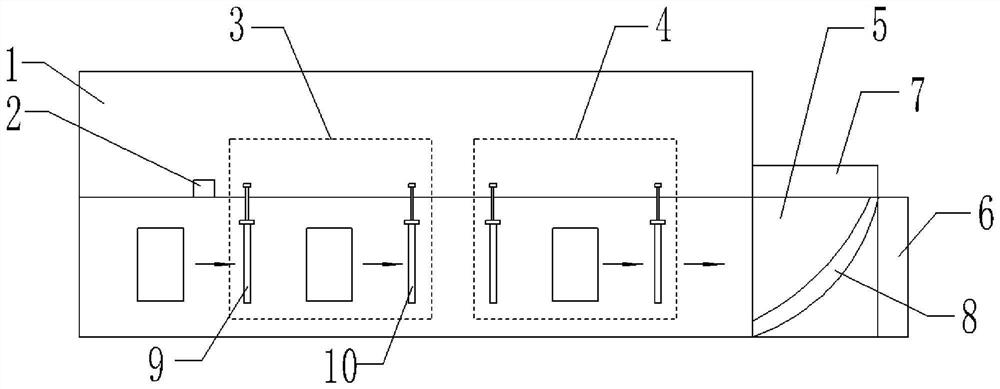

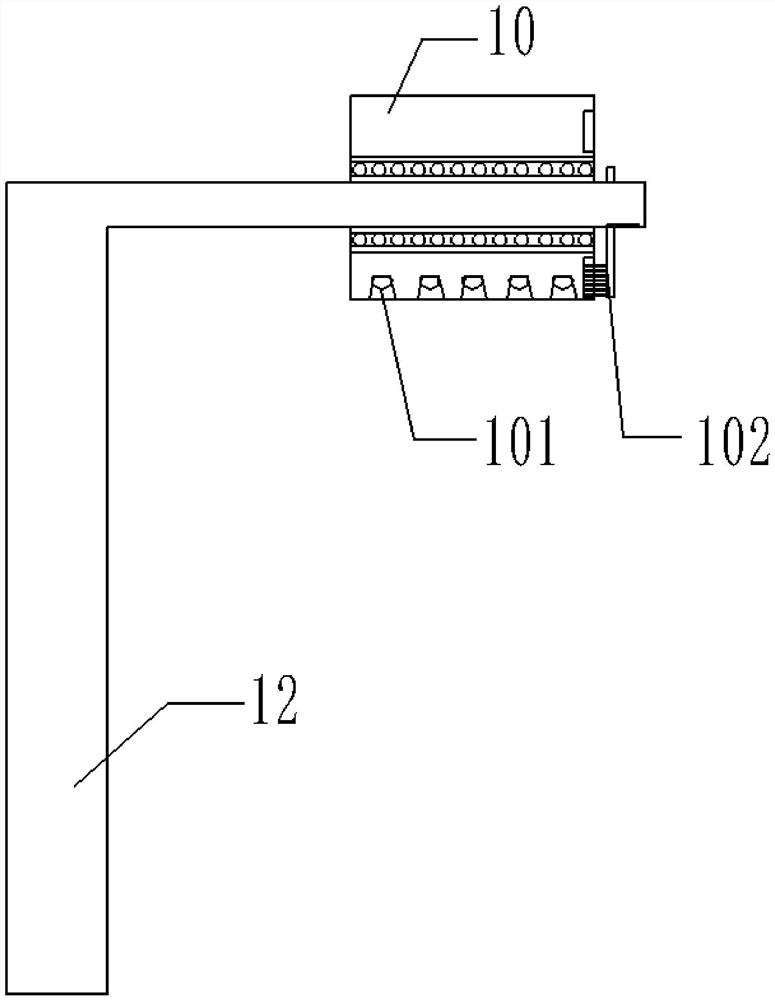

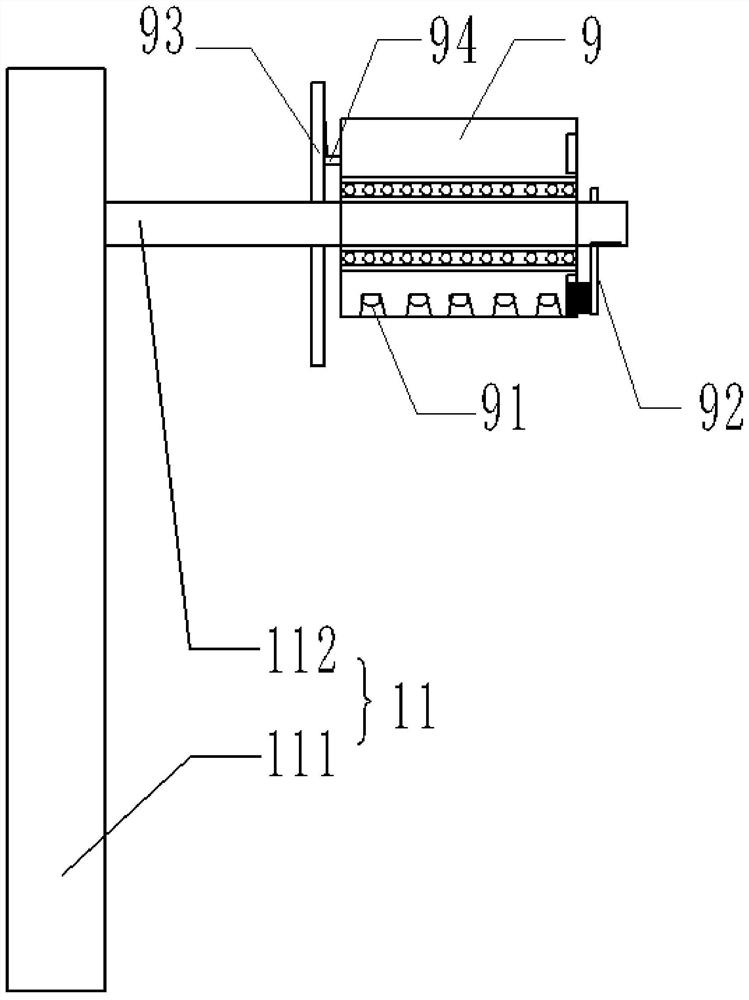

[0047] like figure 1 As shown, a workpiece surface defect detection system includes a frame 1 , a transmission device, an image acquisition device, an image summarization module and a distribution device 8 . The conveyor is mounted on the frame 1, including conveyor belts for placing workpieces. The rack 1 is provided with a reading device 2 on the rear left of the conveyor belt. The reading device 2 is used to read the RFID tags on the surface of the workpiece. Each workpiece has a unique RFID tag, and each RFID tag also corresponds to a unique workpiece. There are two image acquisition devices, namely the first image acquisition device 3 on the left and the second image acquisition device 4 on the right; each image acquisition device includes a light source emitter 9 and a light sensing board 10, and the frame 1 is fixed with The first support rod 11 and the second support rod 12, the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com