Zero cold water system and gas water heater

A zero-cold water and water heater technology, applied in fluid heaters, lighting and heating equipment, functional valve types, etc., can solve problems such as excessively long circulation loops and large circulation air consumption, and achieve small circulation air consumption, reduce air consumption, The effect of sufficient water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The present invention is further illustrated below by means of examples, but the present invention is not limited thereto within the scope of examples.

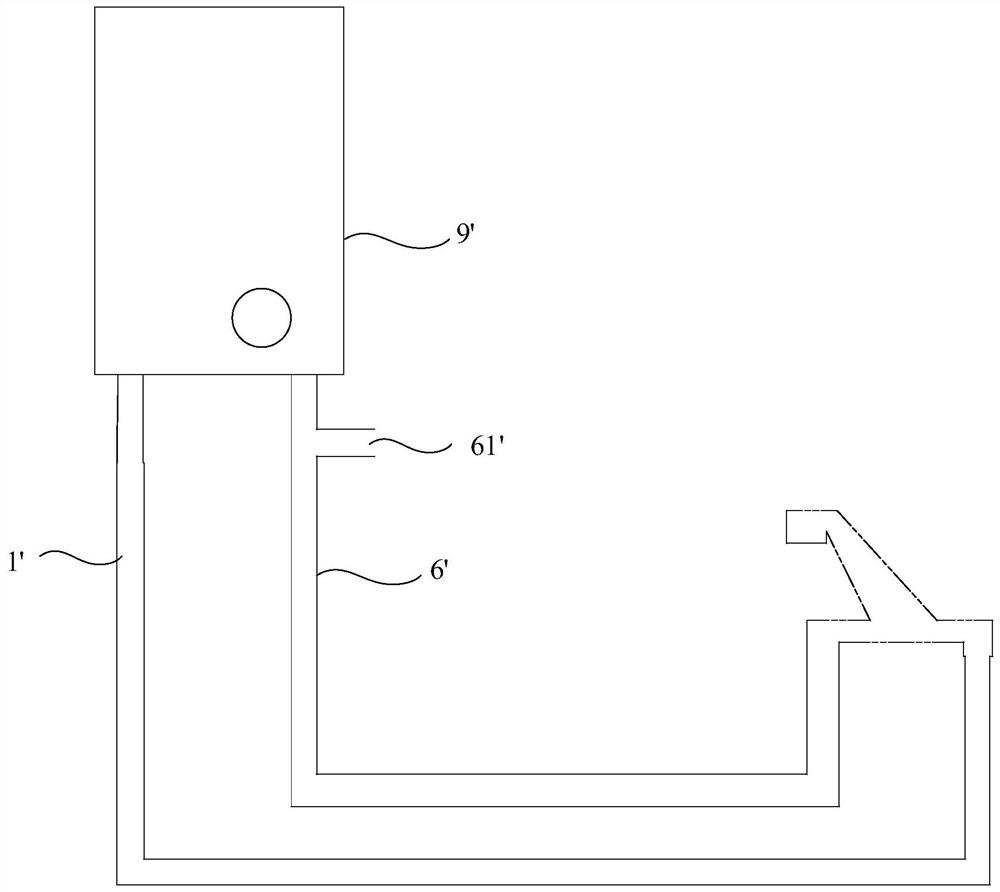

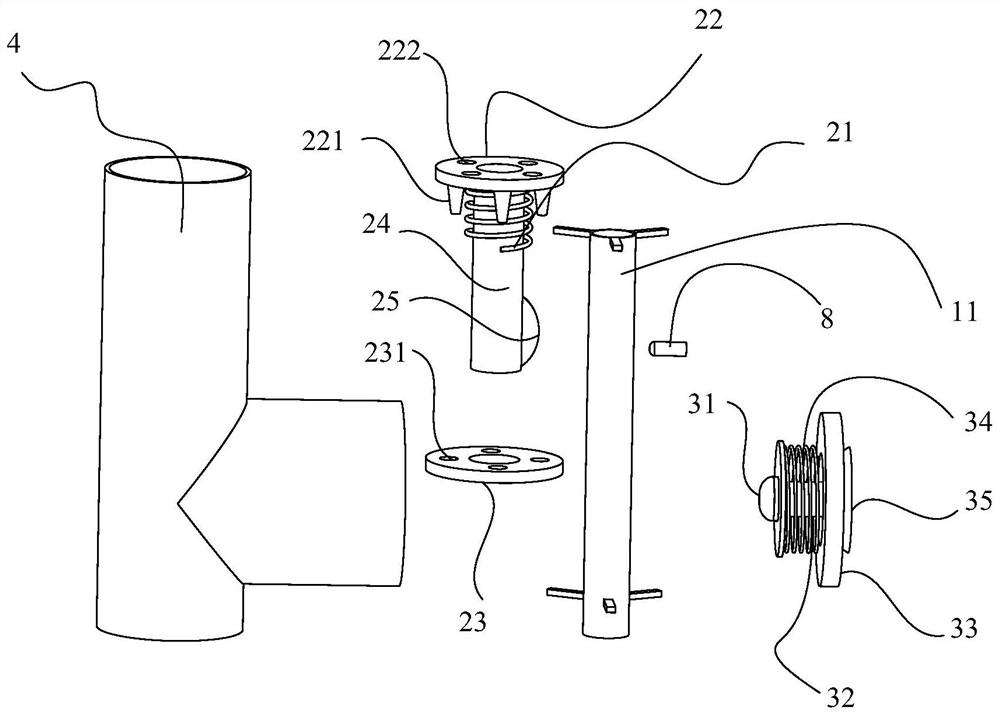

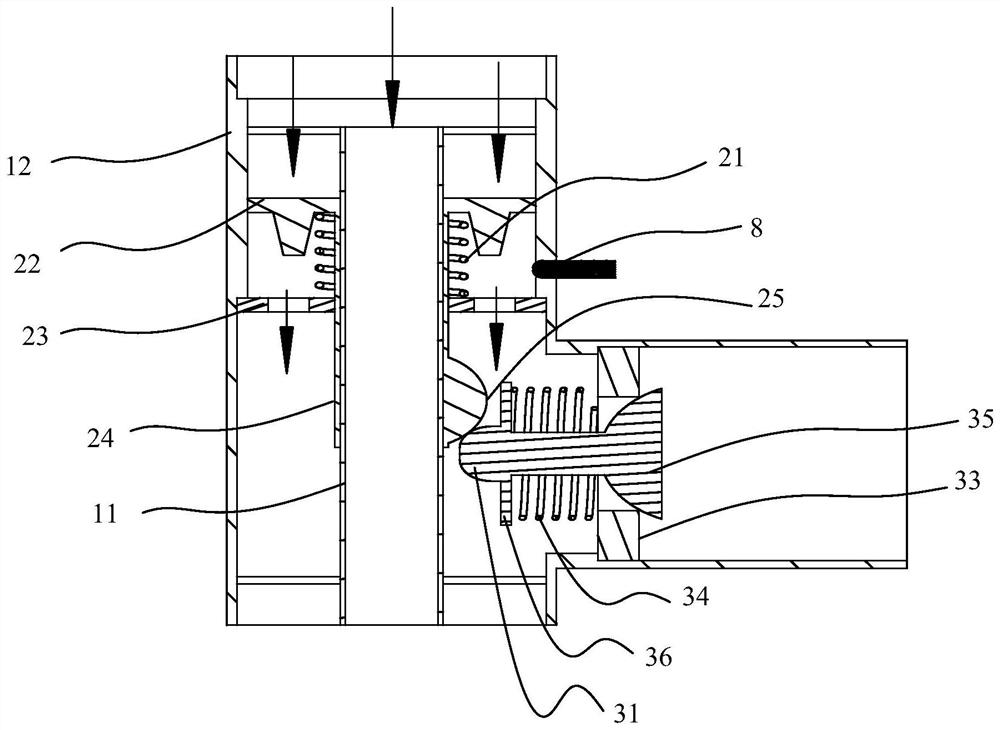

[0079] This embodiment discloses a zero cooling water system. Such as Figure 2-4 As shown, the zero cold water system includes a water heater 9, a cold water pipe 6 and a hot water pipe 1, the cold water pipe 6 is connected to the inlet of the water heater 9, the hot water pipe 1 is connected to the outlet of the water heater 9, and the hot water pipe 1 includes an inner pipe 11 and a sleeve The outer pipe 12 arranged in the inner pipe 11, the inside of the inner pipe 11 forms an inner passage, and the outer passage is formed between the inner pipe 11 and the outer pipe 12, and the inner passage and the outer passage communicate with each other at the end of the hot water pipe 1 away from the water heater 9, The zero cold water system also includes a circulation pipe 5, a first adjustment mechanism 2 and a second adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com